Method for extracting CBD and CBDV at same time

A technology of extracting liquid and eluting liquid, which is applied in the field of chemistry, can solve problems such as waste of resources, and achieve the effects of low cost, reduced impact on the environment and operators, and simple and easy operation and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

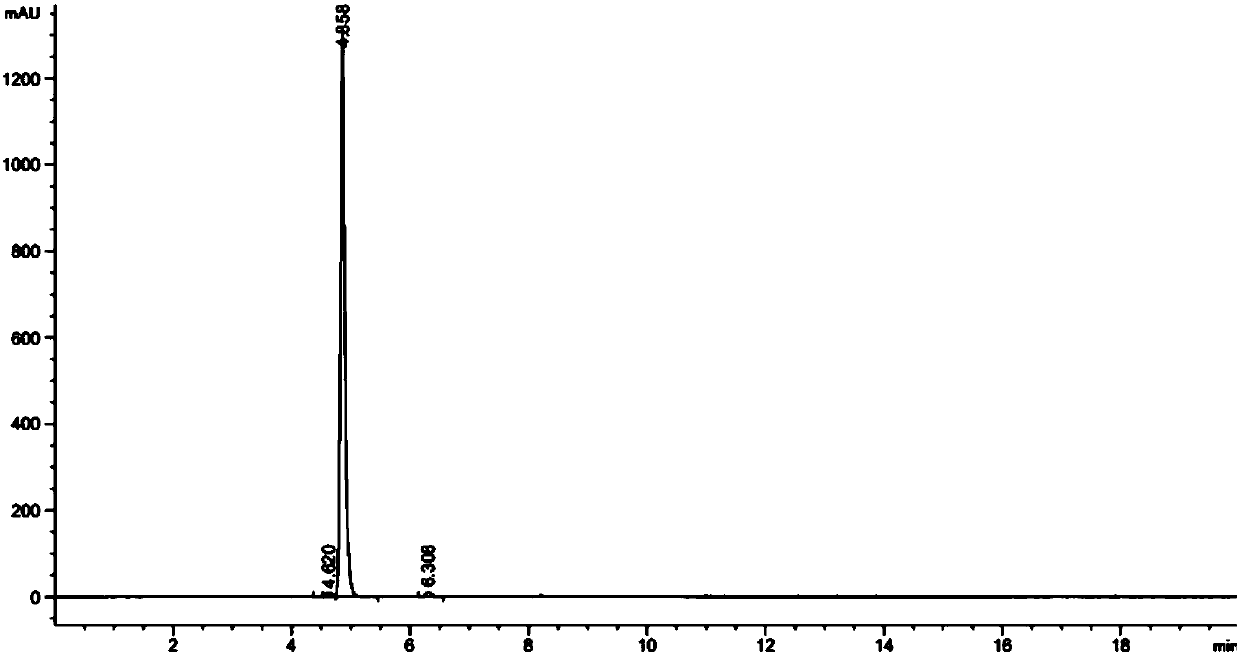

[0085] The process steps of simultaneously extracting CBDV and CBD are as follows:

[0086] 1) Grinding industrial hemp flower and leaf raw materials into 40-mesh coarse powder, baking at 105°C for 80 minutes, and the measured moisture content is 3.6%;

[0087] 2) soak the medicinal material obtained in step 1) with 6 times 95% ethanol at room temperature for 1 hour, extract by cold soaking method 3 times, and combine to obtain the extract;

[0088] 3) Concentrate the extract obtained in step 2) at 55°C to an alcohol content of 50%, add 95% ethanol to adjust the alcohol content to 60%, settle overnight, and obtain the supernatant;

[0089] 4) Pass the supernatant obtained in step 3) through the large-pore HPD 100 resin, wash 2BV with purified water, wash 4BV with 60% ethanol, start collecting CBDV from liquid chromatography, and stop when the concentration of CBDV is lower than 0.5g / L Collect the remaining part as waste liquid recovery solvent; then elute 5BV with 80% ethanol...

Embodiment 2

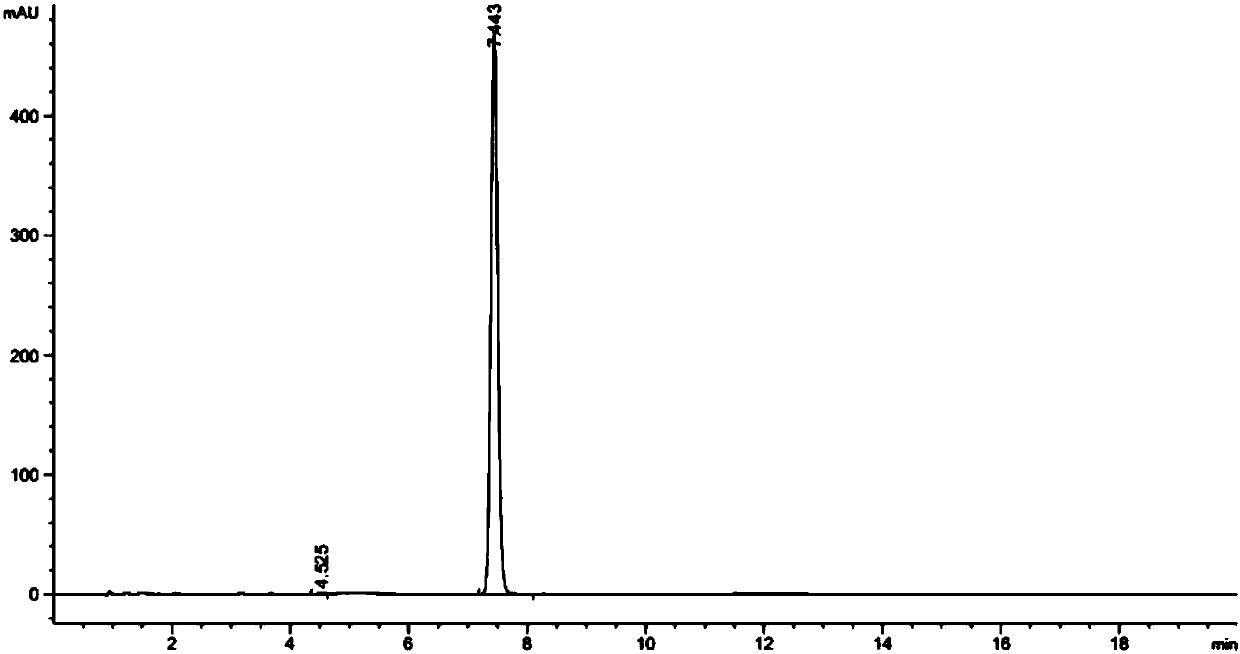

[0096] The process steps of simultaneously extracting CBDV and CBD are as follows:

[0097] 1) Grinding the raw material of industrial hemp mosaic leaves into 60-mesh coarse powder, baking at 150°C for 30 minutes, and the measured moisture content is 3.2%;

[0098] 2) Soak the medicinal material obtained in step 1) with 10 times 95% ethanol at room temperature for 1 hour, extract twice by cold soaking, and combine to obtain the extract;

[0099] 3) Concentrate the extract obtained in step 2) at 65°C to an alcohol content of 72%, filter with a plate and frame, and obtain a supernatant;

[0100] 4) Put the supernatant obtained in step 3) over HZ18 macroporous resin overnight, wash 3BV with purified water, wash 4BV with 60% ethanol, start collecting CBDV from the liquid phase inspection, and stop collecting when the concentration of CBDV is detected to be lower than 0.5g / L. Partially make waste liquid recovery solvent; then elute 5BV with 76% ethanol, start collecting from the l...

Embodiment 3

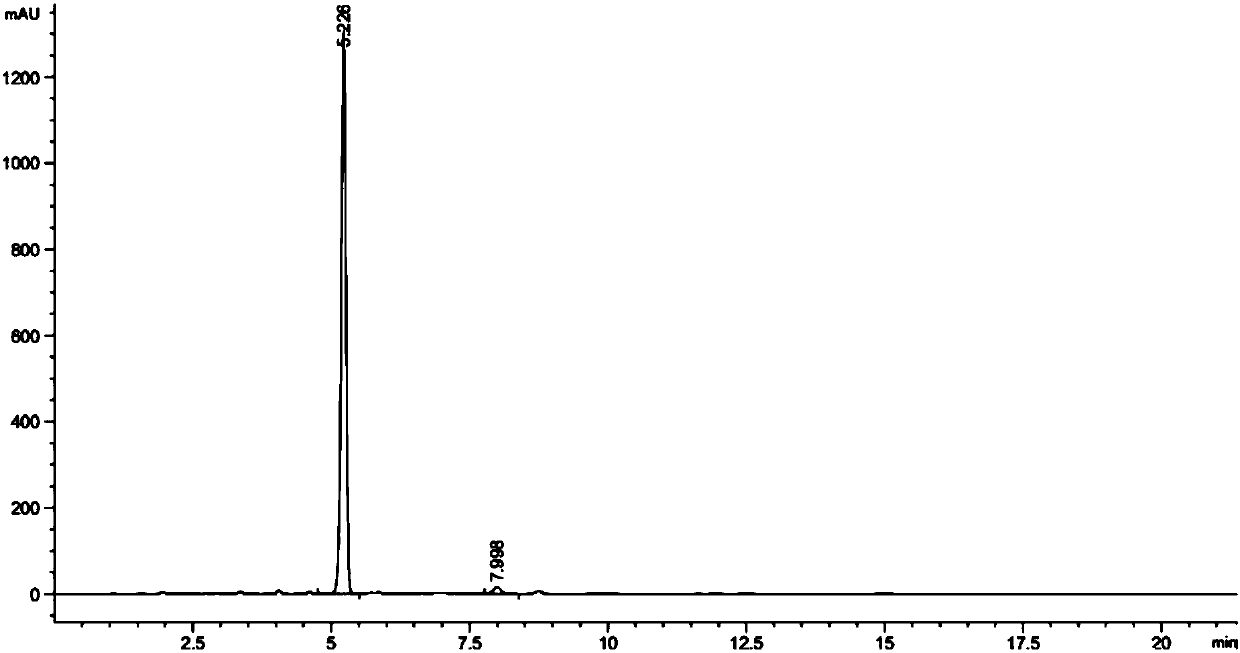

[0108] The process steps of simultaneously extracting CBDV and CBD are as follows:

[0109] 1) Grinding the raw material of industrial hemp mosaic leaves into 20-mesh coarse powder, baking at 120°C for 40 minutes, and the water content is 3.5%;

[0110] 2) Soak the medicinal material obtained in step 1) with 7 times 80% ethanol at 60°C for 1 hour, extract twice by cold soaking, and combine to obtain the extract;

[0111] 3) Concentrate the extract obtained in step 2) at 70°C to an alcohol content of 65%, filter with a plate and frame, and obtain a supernatant;

[0112] 4) Put the supernatant obtained in step 3) over D101 macroporous resin overnight, wash 2BV with purified water, wash 4BV with 65% ethanol, start collecting CBDV from the liquid phase inspection, and stop collecting when the CBDV concentration is lower than 0.5g / L. Partially make waste liquid recovery solvent; then elute 6BV with 82% ethanol, start collecting from the liquid phase inspection to CBD, and stop col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com