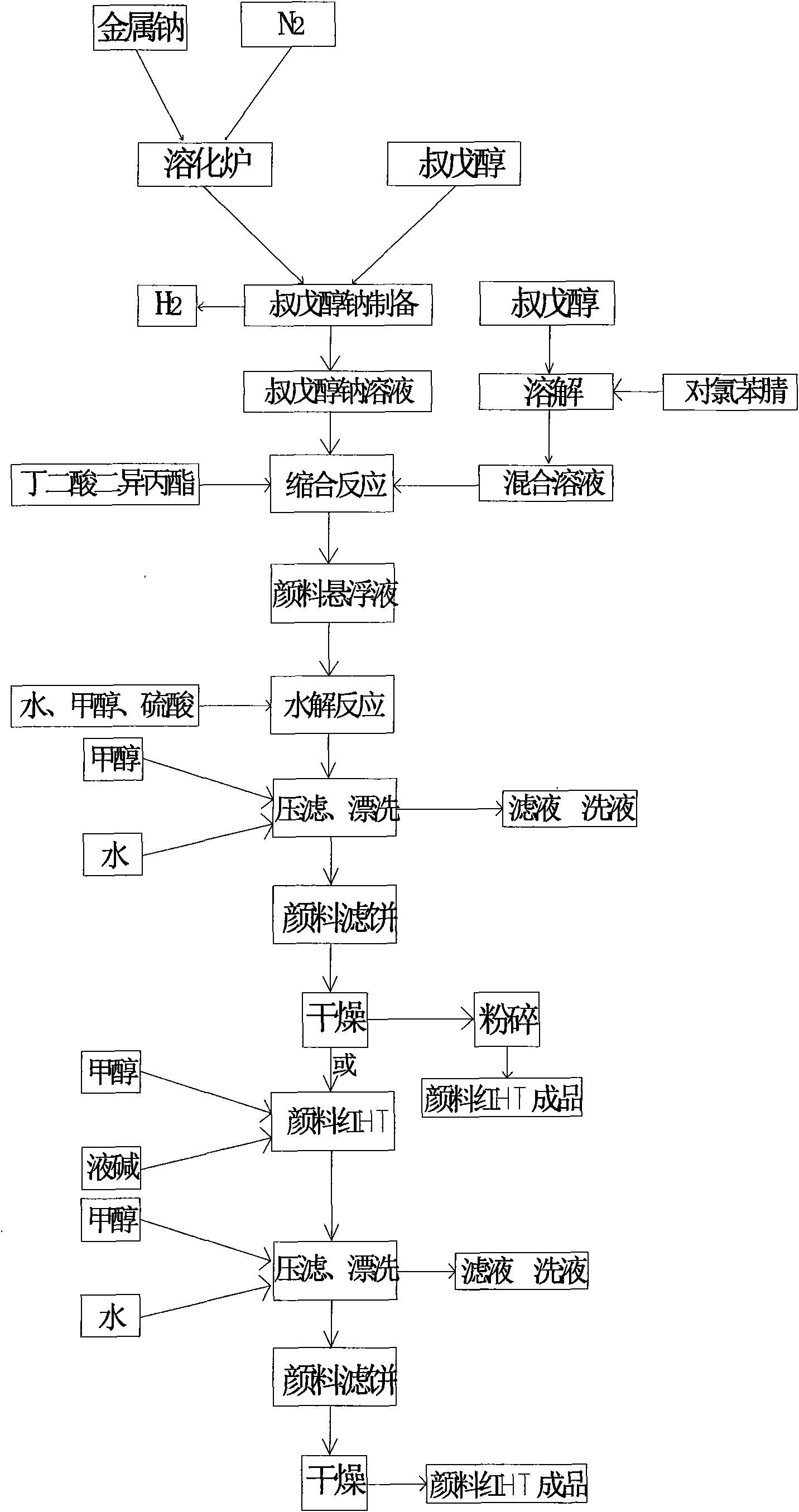

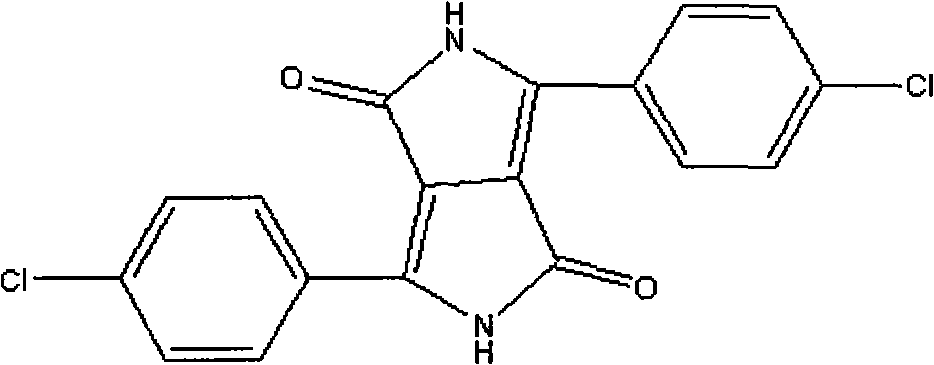

Production process of pigment red HT

A production process, pigment red technology, applied in the chemical industry, can solve problems such as low work efficiency and production quality, low catalytic activity of sodium tert-amylate, uneven pigment particles, etc., to achieve good batch stability and easy operation , the effect of fine particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

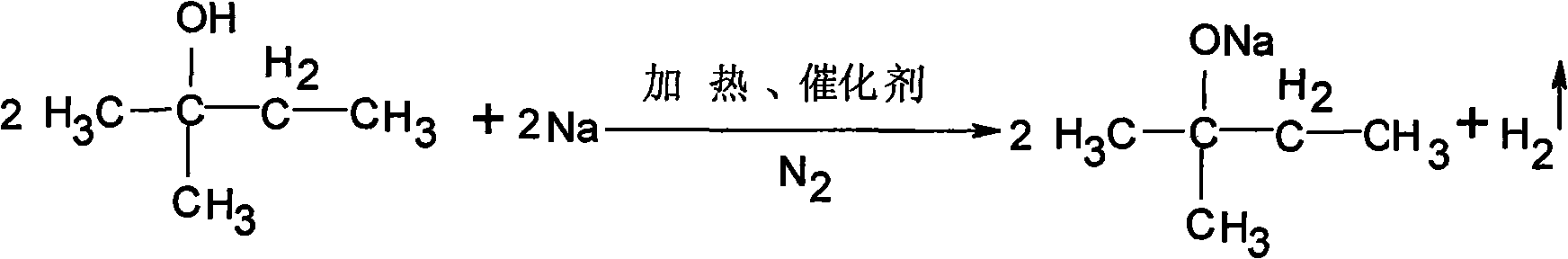

Embodiment 1

[0032] The production process of Pigment Red HT uses p-chlorobenzonitrile, diisopropyl succinate, sodium metal, methanol, and tert-amyl alcohol as basic raw materials. The steps are as follows: first, pour N into a 500L stainless steel melting pot 2 , and then after raising the temperature to 160°C, all 282 kg of sodium metal was added into the stainless steel melting pot. After the sodium metal was completely melted, N was introduced into the stainless steel sodium alkoxide preparation kettle. 2 , and keep the preparation kettle dry, then add 2127 kg of solvent tert-amyl alcohol solvent, stir and heat up to 101 ° C, then add molten sodium metal to the preparation kettle over a period of 0.4-0.6 hours, and control the stirring speed to 80 rpm / min, warming up to the reflux state, under the reflux state, gradually add dropwise 100ml concentration of 5% ferric trichloride tert-amyl alcohol solution, after the temperature reaches 119°C, start to feed N 2 , kept for 1h, at this ti...

Embodiment 2

[0036] First pass N into the 500L stainless steel melting pot 2 , and then raise the temperature to 150°C, add 260 kg of sodium metal into the stainless steel melting pot, and after the sodium metal is completely melted, pour N into the stainless steel sodium alkoxide preparation kettle. 2 , and keep the preparation kettle dry, then add 2080 kg of tert-amyl alcohol solvent, stir and heat up to 101-105°C, then add molten sodium metal into the preparation kettle over a period of 0.4-0.6h, and control the stirring speed to 80 Turn per minute, heat up to reflux state, under reflux state, gradually add dropwise 90ml of ferric trichloride tert-amyl alcohol solution with a mass concentration of 5% as a catalyst, after the temperature reaches 115-122°C, start to feed N 2, keep 1h to complete the oxidation-reduction reaction to obtain sodium tert-amylate;

[0037] In the 5000L condensation reactor, N 2 , then add 280 kg of solvent tert-amyl alcohol, heat up to 100-105°C, then cool do...

Embodiment 3

[0040] The production process of Pigment Red HT uses p-chlorobenzonitrile, diisopropyl succinate, sodium metal, methanol, and tert-amyl alcohol as basic raw materials. The steps are as follows: first, pour N into a stainless steel melting pot 2 , and then after raising the temperature to 180°C, all 300 kg of sodium metal was added into the stainless steel melting pot. After the sodium metal was completely melted, N was introduced into the stainless steel sodium alkoxide preparation kettle. 2 , and keep the preparation kettle dry, then add 2160 kg of tert-amyl alcohol solvent, stir and heat up to 101-105°C, then add molten sodium metal into the preparation kettle over a period of 0.4-0.6h, and control the stirring speed to 80 RPM, heat up to reflux state, under reflux state, gradually drop 110ml of ferric trichloride tert-amyl alcohol solution with a mass concentration of 5% as a catalyst, after the temperature reaches 115-122°C, start to feed N 2 , keep 1h to complete the oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| photostability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com