Preparation method of hexamethylene diisocyanate tripolymer curing agent

A trimerization technology of hexamethylene diisocyanate and isocyanate, applied in organic chemistry, polyurea/polyurethane coatings, coatings, etc., can solve the problems of high reaction temperature, low catalytic efficiency, easy to produce by-products, etc., and achieve catalytic High efficiency, increase heat transfer area, and save solvent cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

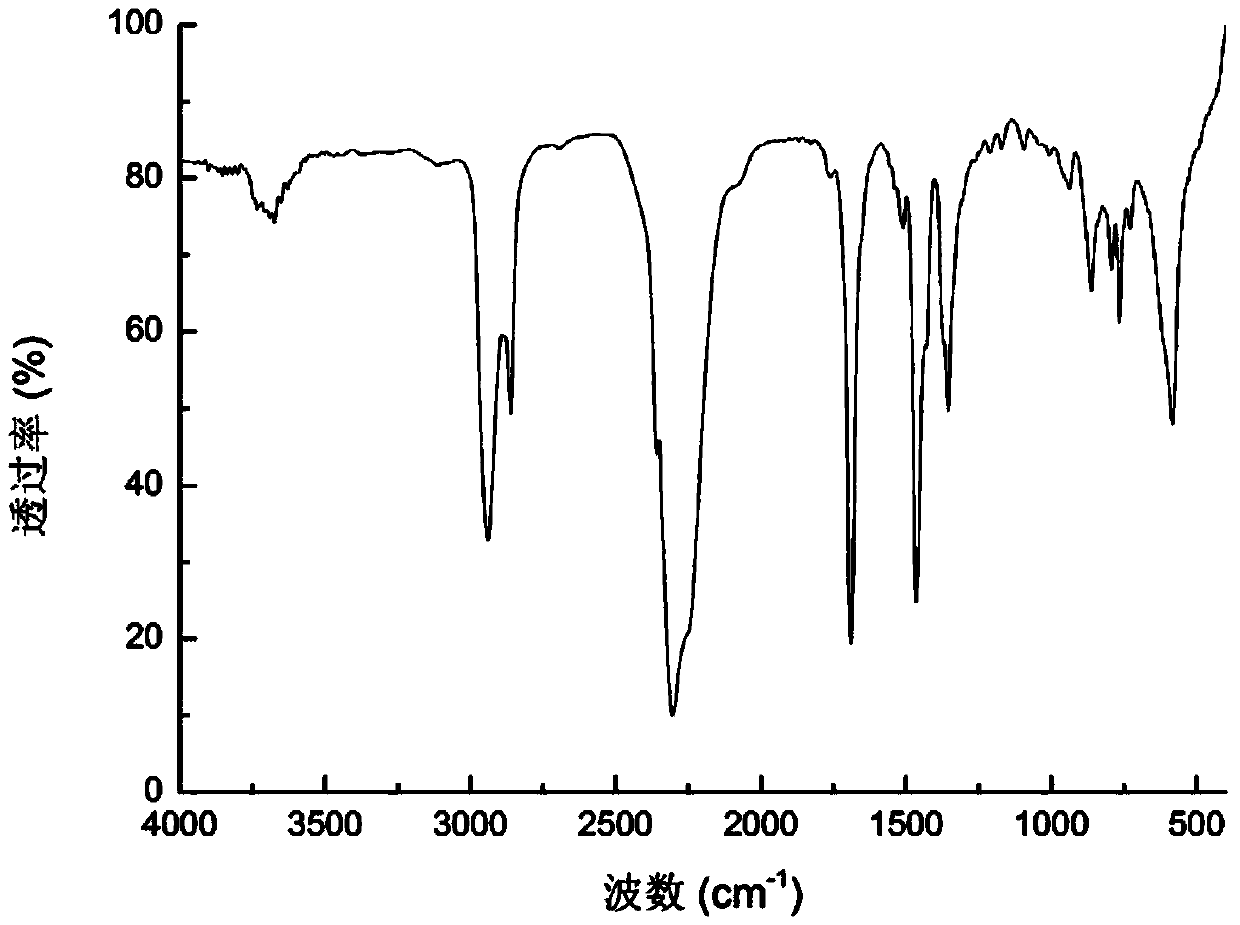

Image

Examples

Embodiment 1

[0026] Preparation of 2-hydroxyalkyl quaternary ammonium base: in parts by mass, under nitrogen protection, 38 parts of propylene oxide were added dropwise to a system of 65 parts of triethylamine and 12 parts of water within 1 h to maintain the system The temperature is 30°C. After the addition of propylene oxide was completed, the stirring continued for 12 hours. After the reaction was stopped, the yellow liquid in the lower layer was separated with a rotary evaporator to obtain the product 2-hydroxyalkyl quaternary ammonium base in the form of yellow oil. In the prior art, quaternary ammonium salt catalysts are used to catalyze aromatic highly active diisocyanates such as TDI. For aliphatic diisocyanates (such as HDI, IPDI) with weak monomer activity, the catalytic activity of quaternary ammonium salts is very small. Except for special quaternary ammonium salts with fatty chain segments (for example, 2-hydroxypropyltrimethylisooctanoic acid ammonium salt), which are oily ...

Embodiment 2

[0032] Preparation of 2-hydroxyalkyl quaternary ammonium base: under the protection of nitrogen, 25.94g of propylene oxide was added dropwise to 80g of trimethylamine aqueous solution (33% by mass), and the dropwise addition was completed in one hour. Stirring was continued at 35 °C for 24 h. After stopping the reaction, the yellow liquid in the lower layer was separated with a rotary evaporator to obtain the product 2-hydroxyalkyl quaternary ammonium base in the form of light yellow oil.

[0033] (1) Put 100g of HDI monomer into the reaction container under the protection of nitrogen, and dropwise add the trimerization catalyst 2-hydroxyalkyl quaternary ammonium base prepared by accounting for more than 0.2% of the mass of isocyanate monomer within 1.5h, maintain the temperature at 40°C, and keep it warm Stirring and reacting for 8h; when the mass percentage of free NCO groups was measured to be 35%, add a phosphoric acid polymerization inhibitor accounting for 0.3% of the ma...

Embodiment 3

[0036] The preparation method of 2-hydroxyalkyl quaternary ammonium base: use 72.11 parts of methyl propylene oxide, add dropwise to the mixed solution of 101.19 parts of triethylamine and 18 parts of water, and continuously stir at 40°C for 12h. After stopping the reaction, the yellow liquid in the lower layer was separated with a rotary evaporator to obtain the product 2-hydroxyalkyl quaternary ammonium base in the form of light yellow oil.

[0037] (1) Put 100g of HDI monomer into the reaction container under the protection of nitrogen, add the trimerization catalyst prepared by accounting for more than 0.5% of the mass of the isocyanate monomer dropwise within 1 hour, maintain the temperature at 80 ° C, keep stirring for 2 hours; measure the free NCO group When the mass percentage of the mass is 40%, add 0.5% acetyl chloride polymerization inhibitor accounting for the mass of the isocyanate monomer, and keep warm for 0.5h; stop the reaction, and after cooling down to room t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com