Ultraviolet curing coating

A technology for curing coatings and UV light, applied in polyester coatings, polyurea/polyurethane coatings, coatings, etc., to achieve the effects of good weather resistance, low yellowing and high curing activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

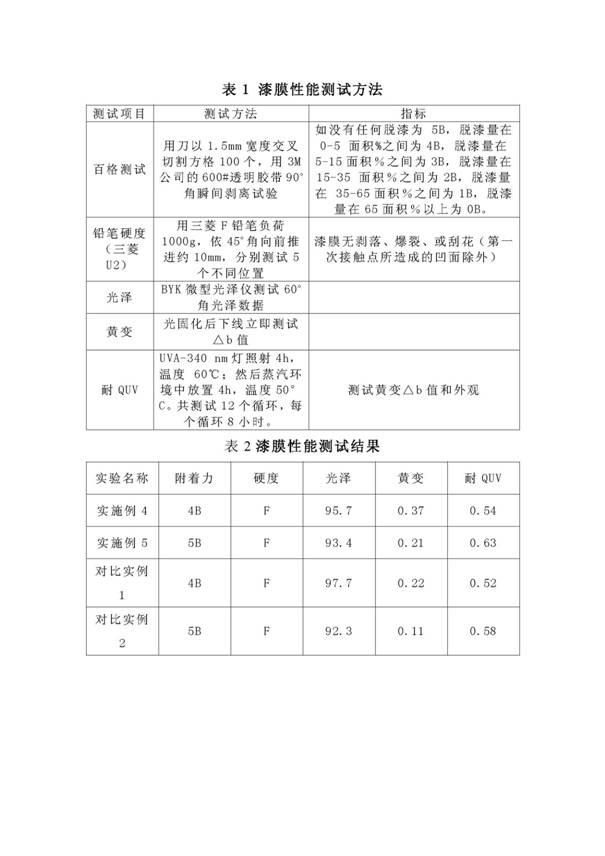

Examples

Embodiment 1

[0037] Example 1 (Synthesis of low yellowing initiator):

[0038] Into a 5000ml four-necked flask with a condenser, thermometer, air duct, and mechanical stirrer, pass dry air into it, turn on the stirrer, add 2661.6g butyl acrylate after 10 minutes, and dissolve 0.7g pair with 20.0g butyl acetate. Methoxyphenol (MQ), 1.4g 2,6-di-tert-butyl-p-cresol (BHT), add the above solution into the reactor under stirring conditions, weigh 35.6g DBU, and add dropwise to the reactor under stirring conditions, Slowly heat up to 45°C; weigh 1000.0g of acetylacetone, use a constant-pressure dropping funnel to add dropwise within the time range of 150-180min, wash the funnel with 30gB solvent, keep it at 45-55°C for 4h, discharge, and obtain a red-yellow liquid; Place the above liquid in an environment of 0°C for 24h, take it out, and grind into a powder. The low-yellowing initiator 4,4 diacetylpimelate dibutyl ester provided by the present invention is obtained.

Embodiment 2

[0039] Example 2 (Synthesis of low yellowing initiator):

[0040] Into a 5000ml four-necked flask with a condenser, thermometer, air duct, and mechanical stirrer, pass dry air into it, turn on the stirrer, add 2592.6g butyl acrylate after 10 minutes, and dissolve 0.7g pair with 20.0g butyl acetate. Methoxyphenol (MQ), 1.4g 2,6-di-tert-butyl-p-cresol (BHT), add the above solution into the reactor under stirring conditions, weigh 30.2g DBN, and add dropwise to the reactor under stirring conditions, Slowly increase the temperature to 45°C; weigh 1100.0g ethyl acetoacetate, use a constant-pressure dropping funnel to add dropwise within a time range of 150-180min, wash the funnel with 30gB solvent, keep it at 45°C for 4h, discharge, and obtain a red-yellow liquid; Place the above liquid in an environment of 0°C for 24h, take it out, and grind into a powder. The low-yellowing initiator 4,4 diacetylpimelate diethyl ester provided by the present invention is obtained.

Embodiment 3

[0041] Example 3 (Synthesis of low yellowing initiator):

[0042] Into a 5000ml four-necked flask with condenser, thermometer, air duct, and mechanical stirrer, pass dry air into it, turn on the stirrer, add 2676.6g methyl acrylate after 10 minutes, dissolve 0.7g pair with 20.0g butyl acetate Methoxyphenol (MQ), 1.4g 2,6-di-tert-butyl-p-cresol (BHT), add the above solution into the reactor under stirring conditions, weigh 35.6g DBU, and add dropwise to the reactor under stirring conditions, Slowly heat up to 45°C; weigh 1200.0g of acetylacetone, use a constant-pressure dropping funnel to add dropwise within the time range of 150-180min, wash the funnel with 30gB solvent, keep it at 45°C for 4h, discharge, and obtain a red-yellow liquid; The liquid is placed in a 0℃ environment for 24h, taken out, and ground into powder. Obtain the low-yellowing initiator 4,4 dimethyl diacetylpimelate provided by the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com