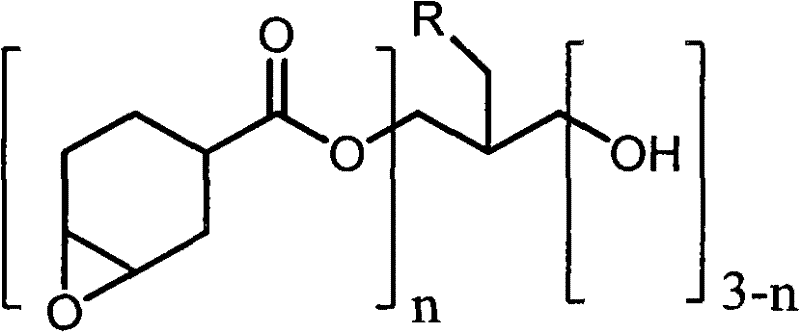

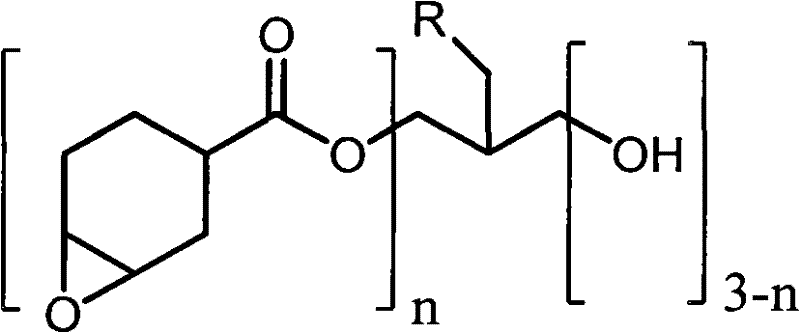

Hydroxyl-contained alicyclic epoxy resin and preparation method thereof

A technology of epoxy resin and hydroxyl ester, which is applied in the field of hydroxyl-containing alicyclic epoxy resin and its preparation, can solve the problems of low reactivity, decreased thermal performance of epoxy resin, and color introduction, and achieve chemical modification performance Good, increase curing activity, excellent heat resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Mix 100g (0.73mol) of pentaerythritol, 229g (1.46mol) of methyl 3,4-epoxycyclohexanecarboxylate and 0.16g of isopropyl titanate, and react at 150°C for 3 hours under the protection of an inert gas. The methanol produced by the reaction is discharged with the inert gas during the reaction, and finally the hydroxyl-containing alicyclic epoxy resin is obtained, IR: 3450cm-1(-OH), 1726cm-1(-COO-).

[0022] Take the above 10g of hydroxyl-containing alicyclic epoxy resin and 2.57g of p, p’-diaminodiphenylmethane and mix thoroughly, and cure according to the program of 90°C / 3h+150°C / 2h+180°C / 2h. The impact strength of the cured product is 20kJ m-2 (the impact strength is measured by a pendulum impact tester, the sample is a cuboid with a size of 60×6×4.5mm3), Tg 140°C (after the sample is cured, it is ground into powder , tested with a Perkin-Elmer DSC-2C differential scanning calorimeter produced by PE Company in the United States, N2 atmosphere, and the heating rate is 20 °C...

Embodiment 2

[0024] Mix 100g (0.75mol) of trimethylolpropane, 233g (1.50mol) of methyl 3,4-epoxycyclohexanecarboxylate and 3.3g of dibutyltin dilaurate at 80°C under the protection of an inert gas After 12 hours of reaction, the methanol produced by the reaction was discharged with the inert gas during the reaction, and finally a hydroxyl-containing alicyclic epoxy resin was obtained.

[0025] Take the above 10g of hydroxyl-containing alicyclic epoxy resin and 8.79g of methyl hexahydrophthalic anhydride, mix thoroughly, and cure according to the program of 90°C / 3h+150°C / 2h+180°C / 2h. The impact strength of the cured product is 20kJ·m-2 (the test method is the same as above), and the Tg is 145°C (the test method is the same as the above).

Embodiment 3

[0027] Mix 100g (0.75mol) trimethylolpropane, 233g (1.50mol) methyl 3,4-epoxycyclohexanecarboxylate and 1.6g sodium acetate, and react at 110°C for 5 hours under the protection of an inert gas , The methanol produced by the reaction is discharged with the inert gas during the reaction, and finally the hydroxyl-containing alicyclic epoxy resin is obtained.

[0028] Take the above 10g of hydroxyl-containing alicyclic epoxy resin and 7.0g of hexahydrophthalic anhydride and mix thoroughly, and cure according to the program of 120°C / 3h+150°C / 3h+200°C / 3h. The impact strength of the cured product is 21kJ·m-2 (the test method is the same as above), and the Tg is 150°C (the test method is the same as the above).

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com