Sulfur-based electrolyte solution and application thereof in solid lithium battery

A technology of electrolyte solution and solid lithium, which is applied in the direction of non-aqueous electrolyte battery, electrolyte battery manufacturing, secondary battery, etc., and can solve problems such as dead lithium, solid electrolyte layer rupture, and difficulty in mixing the positive electrode and sulfide solid electrolyte evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] This example is used to illustrate the preparation of sulfur-based electrolyte solution. Specifically, the preparation of the preparation of the sulfur-based electrolyte solution is as follows:

[0105] (1) According to the molar ratio of 2:1:1, take the S and Li with a total mass of 0.499g 2 S and P 2 S 5 , was added to 2.5ml of triethylene glycol dimethyl ether (TEGDME), stirred at 30°C and a stirring speed of 20rmp for 72h to prepare a solution of polysulfides, the results are shown in figure 1 .

[0106] Such as figure 1 As shown, the polysulfide was completely dissolved and no precipitation was observed.

[0107] (2) Add lithium salt to the solution prepared in step (1), stir and dissolve, so as to obtain a sulfur-based electrolyte solution, which is numbered as electrolyte 10. The ratio of each component in the electrolyte solution 10 is shown in Table 6.

Embodiment 2

[0109] This example is used to illustrate the preparation of sulfur-based electrolyte solution. Specifically, the preparation of the preparation of the sulfur-based electrolyte solution is as follows:

[0110] (1) According to the molar ratio of 4:3:3, take the S and Li with a total mass of 0.467g 2 S and P 2 S 5 , was added into 4ml of tetrahydrofuran (THF), stirred at 50°C and a stirring speed of 100rmp for 36h to prepare a solution of polysulfides, the results are shown in figure 2 .

[0111] Such as figure 2 As shown, the polysulfide was completely dissolved and no precipitation was observed.

[0112] (2) Add lithium salt to the solution prepared in step (1), stir and dissolve, so as to obtain a sulfur-based electrolyte solution, which is numbered electrolyte 6. The ratio of each component in the electrolyte solution 6 is shown in Table 6.

Embodiment 3

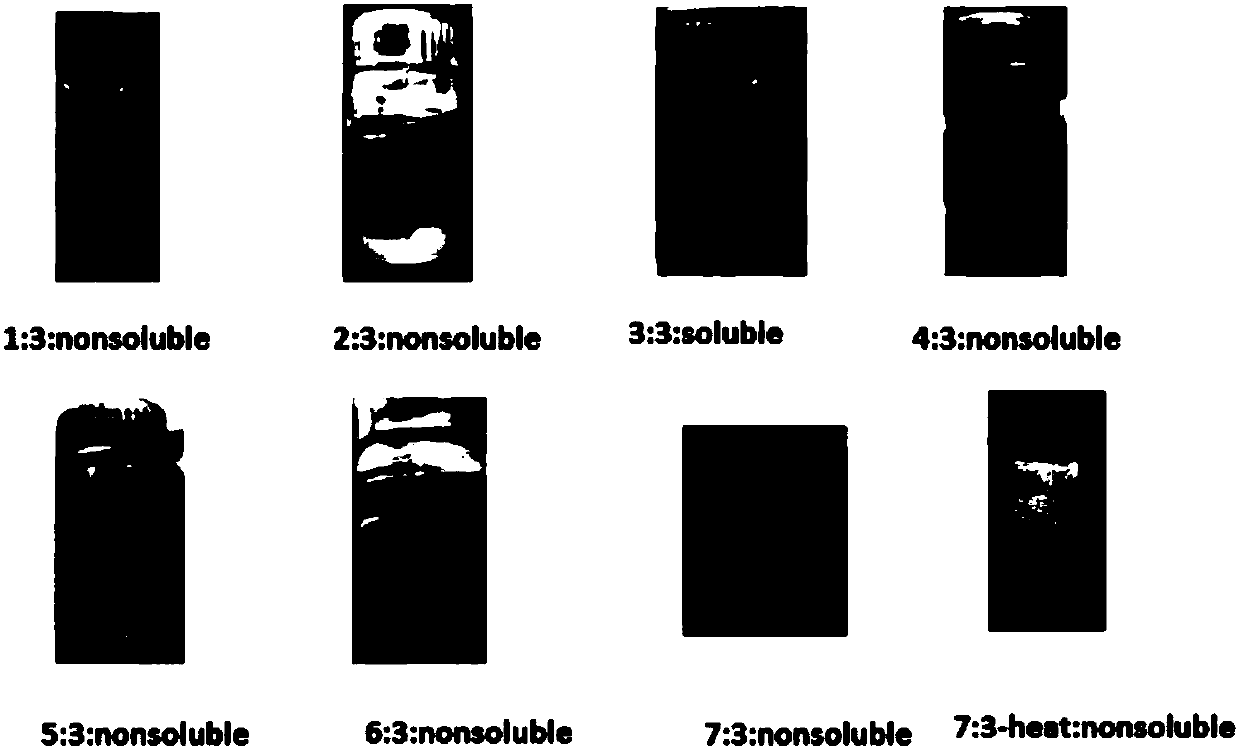

[0114] This example studies the polysulfide Li 2 S-P 2 S 5 Solubility in triethylene glycol dimethyl ether (TEGDME). Specifically, according to the molar ratio of 1:3, 2:3, 3:3, 4:3, 5:3, 6:3, 7:3, the total mass of 0.500g Li 2 S and P 2 S 5 , was added to 2.5ml of triethylene glycol dimethyl ether (TEGDME), stirred at a speed of 100rmp for 48h, wherein, Li 2 S:P 2 S 5 = 7:3 dissolution tests were performed at 60°C, while the rest of the tests were performed at room temperature.

[0115] The result after stirring and dissolving for 48h is as follows image 3 shown. From image 3 It can be seen that different proportions of Li 2 S-P 2 S 5 Solubility is not the same, only in Li 2 S:P 2 S 5 = 3: Dissolved at 3, and the rest of the proportions were not completely dissolved, especially for Li 2 S-P 2 S 5 =7:3 polysulfides, still not dissolved under heating conditions.

[0116] Example 3 shows that the polysulfide Li 2 S-P2 S 5 Solubility in solvents is possibl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com