Lithium ion battery and anode thereof

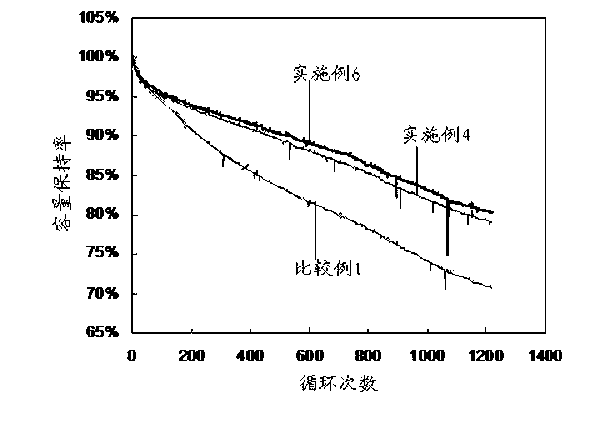

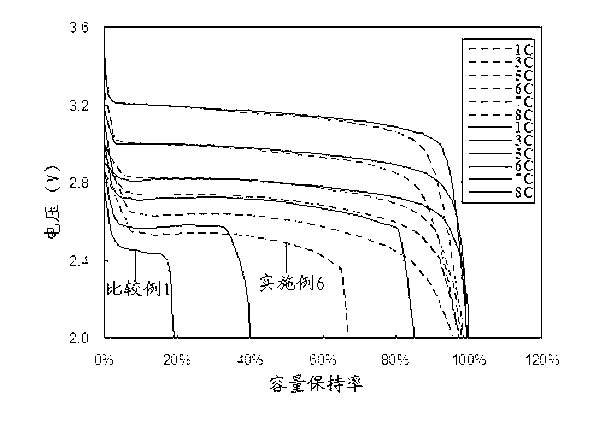

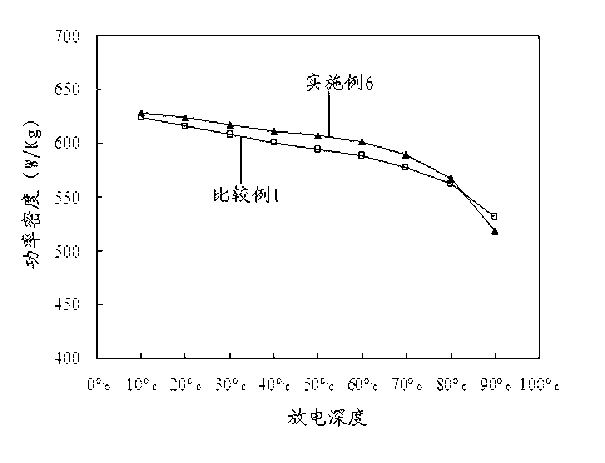

A lithium-ion battery, cathode technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor high temperature and rate performance, improve electrical conductivity, excellent high temperature performance and rate performance, and solve capacity and cycle performance. the effect of decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Weigh 100g of 4A molecular sieve (the particles can pass through 150 mesh sieve) and add it to 300mL LiCl ethanol solution with a concentration of 2mol / L. Keep the container closed, magnetically stir at room temperature for 48h, filter, and clean the filtrate with ethanol , The white powder obtained was dried in a vacuum drying oven at 80°C for 2 hours, and then placed in a vacuum drying oven at 180°C for constant temperature vacuum roasting for 1.5 hours, and finally the obtained powder was activated under reduced pressure and vacuum at 300°C for 2 hours. That is, a lithiation molecular sieve with a lithiation number of 1 time is prepared. Take a small amount of powder and test its lithium content by ICP (Inductively Coupled Plasma).

[0029] Combine lithium iron phosphate, adhesive polyvinylidene fluoride (PVDF), conductive carbon and the above-mentioned lithiated molecular sieve in a mass ratio of 91:2:2:5 (that is, the mass ratio of lithiated molecular siev...

Embodiment 2

[0031] Example 2: The difference from Example 1 is: Weigh 100 g of 3A molecular sieve (the particles can pass through a 200-mesh mesh sieve) and add it to 300 mL of LiNO with a concentration of 1.5 mol / L 3 In the ethanol solution, the container is kept airtight, magnetically stirred at room temperature for 24 hours, filtered, and the filtrate is washed with ethanol. The white powder obtained is dried in a vacuum drying oven at 90°C for 2 hours, and then placed in a vacuum drying oven at 150°C Vacuum roasting at a constant temperature for 1h, and then add the molecular sieve obtained to the above 1.5mol / L LiNO after cooling 3 In the ethanol solution, repeat the above-mentioned stirring, filtering, clearing, drying, roasting and other processes once, and finally the obtained powder is activated under reduced pressure and vacuum at 350℃ for 2.5h, that is, the lithiation with 2 lithiation times is prepared. Molecular sieve. Take a small amount of powder and test its lithium content...

Embodiment 3

[0034] Example 3: The difference from Example 1 is: Weigh 100g of 3A molecular sieve (the particles can pass through a 180 mesh sieve) and add it to 300mL LiClO with a concentration of 1mol / L 4 In the ethanol solution, the container is kept airtight, magnetically stirred at room temperature for 30 hours, filtered, and the filtrate is washed with ethanol. The white powder obtained is dried in a vacuum drying oven at 85°C for 1 hour, and then placed in a vacuum drying oven at 170°C Vacuum roasting at constant temperature for 2h, after cooling, add the obtained molecular sieve to the above 1mol / L LiClO 4 In the ethanol solution, repeat the above-mentioned stirring, filtering, clearing, drying, roasting and other processes twice, and finally the obtained powder is activated under reduced pressure and vacuum at 370℃ for 3h, that is, the lithiation with 3 lithiation times is prepared. Molecular sieve. Take a small amount of powder and test its lithium content by ICP test.

[0035] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com