Catalytic device with internal heat exchange

a technology of heat exchange and catalytic device, which is applied in the direction of fuel cell auxiliaries, exhaust treatment, metal/metal-oxide/metal-hydroxide catalysts, etc., can solve the problems of significant disadvantage in the connection of electric coils, and the electric energy use is affected, so as to reduce or control the heat exchange, reduce or control the effect of heat exchang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

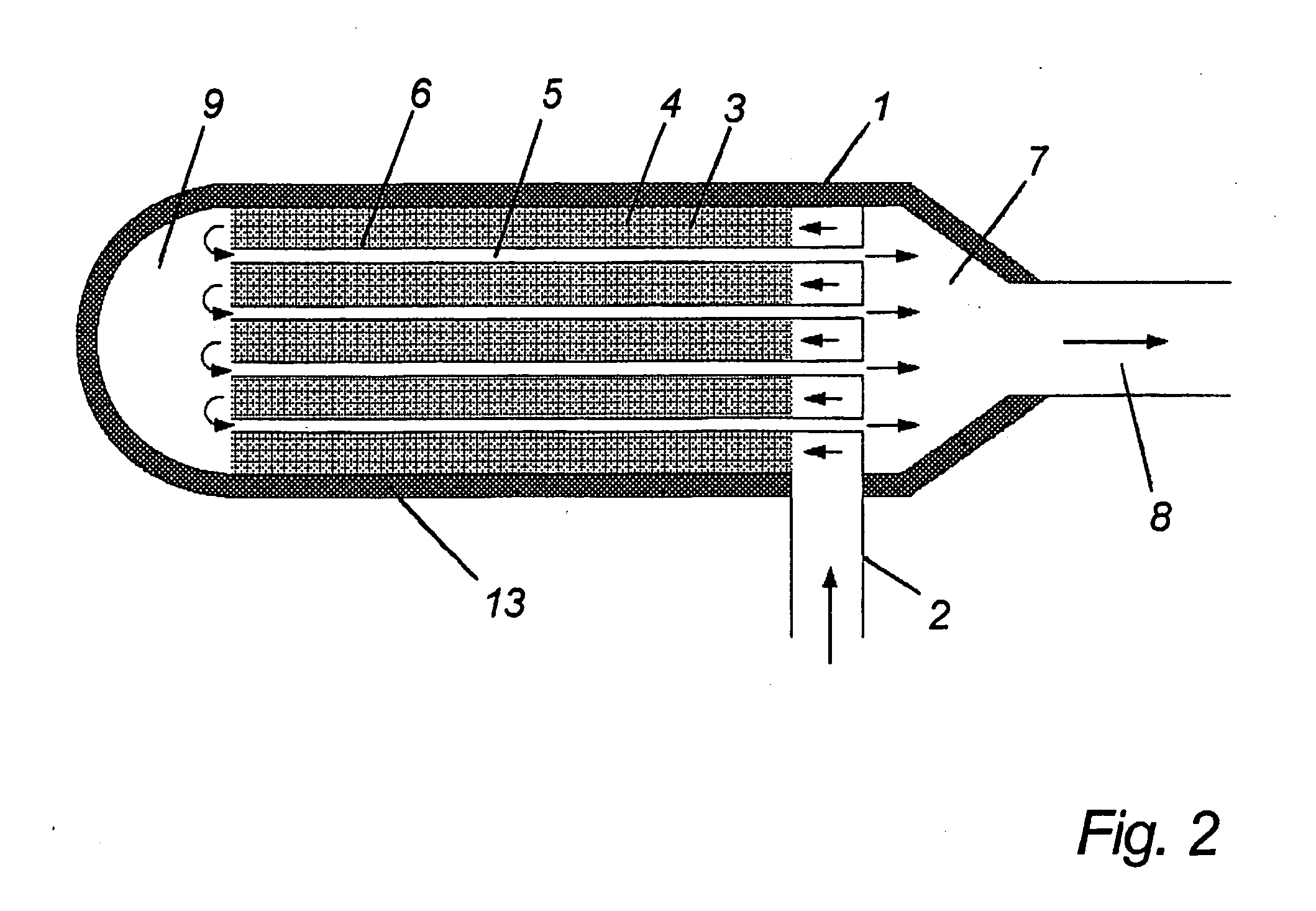

[0143] In a first embodiment that preferably is used in an application involving a gas engine e.g. in connection with a combined power and heat plant, the plant may have a nominal electric effect of 30 kW.

[0144] The length X is approximately 1.0 meter and the height or diameter Y is approximately 0.3 meter. The UHC value (unburned hydrocarbon) is between 3 and 8% of the firing rate to the engine.

[0145] An application with a gas engine may in a preferred embodiment include a catalytic device with at least 50 pipes in a passage section as illustrated in FIGS. 3 to 5 or 15. The diameter of the pipes is approximately 6 to 8 millimeters.

second embodiment

[0146] In a second embodiment that preferably is used in an application involving a gas engine e.g. in connection with a combined power and heat plant, the plant may have a nominal electric effect of 500 kW.

[0147] The length X is approximately 1.5 meter and the height or diameter Y is approximately 0.7 meter. The UHC value (unburned hydrocarbon) is between 3 and 8% of the firing rate to the engine.

[0148] An application with a gas engine may in a preferred embodiment include a catalytic device with at least 200 pipes in a passage section as illustrated in FIG. 3 to 5 or 15. The diameter of the pipes is approximately 8 to 12 millimeters.

third embodiment

[0149] In a third embodiment that preferably is used in an application involving an internal petrol fuelled combustion engine e.g. in connection with vehicles.

[0150] The length X is approximately 0.2 to 0.4 meter and the height or diameter Y is approximately 0.2 meter.

[0151] The UHC value (unburned hydrocarbon) is between 0.5 and 5% of the firing rate to the petrol combustion engine. The value can in a preferred embodiment be raised to approximately 5 to 10% in order to achieve higher temperatures inside the catalytic device by burning further hydrocarbons inside the device. Higher temperatures in the catalytic device mean that catalytic material is saved. Higher values than 10% of the firing rate will affect the efficiency of the petrol combustion engine.

[0152] An application with a petrol combustion engine may in a preferred embodiment include a catalytic device with at least 50 pipes in a passage section as illustrated in FIG. 3 to 5 or 15.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com