Preparation device and preparation method for pressure infiltration-negative pressure adsorption combined metal-matrix composite material

A composite material and metal-based technology, applied in the field of metal-based composite material preparation, can solve the problems of slow speed, poor wettability, and difficulty in preparing reinforced phase distribution, and achieve the effects of uniform distribution, low infiltration pressure and fewer defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

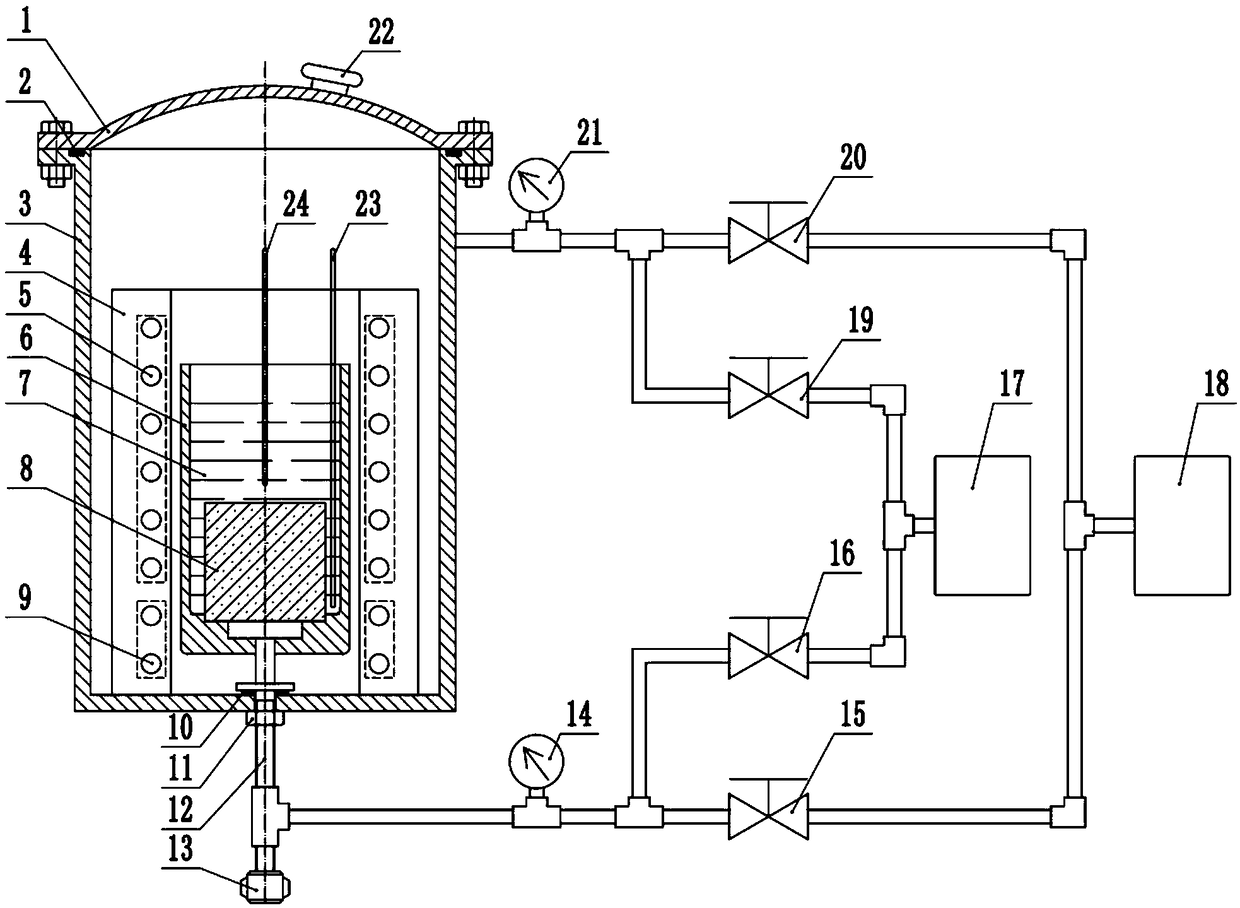

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Preparation of silicon carbide particle-reinforced 6061 aluminum matrix composite material with a high volume fraction of 65%.

[0031] 1. Preparation of silicon carbide reinforced preform: select SiC fine particles of 10 μm and SiC coarse particles of 75 μm to be mixed at a ratio of 3:1, and two kinds of silicon carbide powders with different particle sizes are used as raw materials to prepare reinforced preforms. The specific steps are as follows:

[0032] (1) Cleaning: SiC was placed in NaOH solution, and after ultrasonic cleaning for 20 min, the NaOH solution was replaced and the cleaning was repeated once. Then rinse twice with distilled water, and dry in a constant temperature drying oven at 80°C for later use.

[0033] (2) Powder mixing: mix SiC with starch or glutinous rice flour, SiC volume percentage is 65%, pour into distilled water, add 5wt% water glass, 1wt% zinc stearate, suction filter after wet mixing 3h, will Put the powder in an oven at 80°...

Embodiment 2

[0043] Example 2: A silicon carbide particle reinforced 6061 aluminum matrix composite material with a volume fraction of 47% was prepared.

[0044] When preparing silicon carbide-aluminum matrix composites with a low volume fraction, SiC is mixed with starch or glutinous rice flour in the powder mixing stage of the preform, and the volume percentage of SiC is 47%. In the drying stage, the blank and the mold can be dried together. During pressure adsorption, the pressure of the high-pressure protective gas can be slightly lower, and the vacuum pressure of the lower chamber can be slightly higher, and the other stages are similar to those in Example 1.

Embodiment 3

[0045] Example 3: A silicon carbide particle-reinforced AZ91D magnesium-based composite material with a volume fraction of 67% was prepared.

[0046] When preparing silicon carbide particle-reinforced AZ91D magnesium-based composite materials, the binder can be sodium metasilicate and polyvinyl alcohol. Other preparation processes are similar to the preparation process of silicon carbide particle-reinforced aluminum-based composite materials, except that they are heated to 600 °C in the protective heating stage. It begins to melt at about ℃, pressure infiltration and negative pressure adsorption can be done at 680 ℃, the impregnation pressure is 0.2MPa, and the negative pressure adsorption pressure is 1KPa.

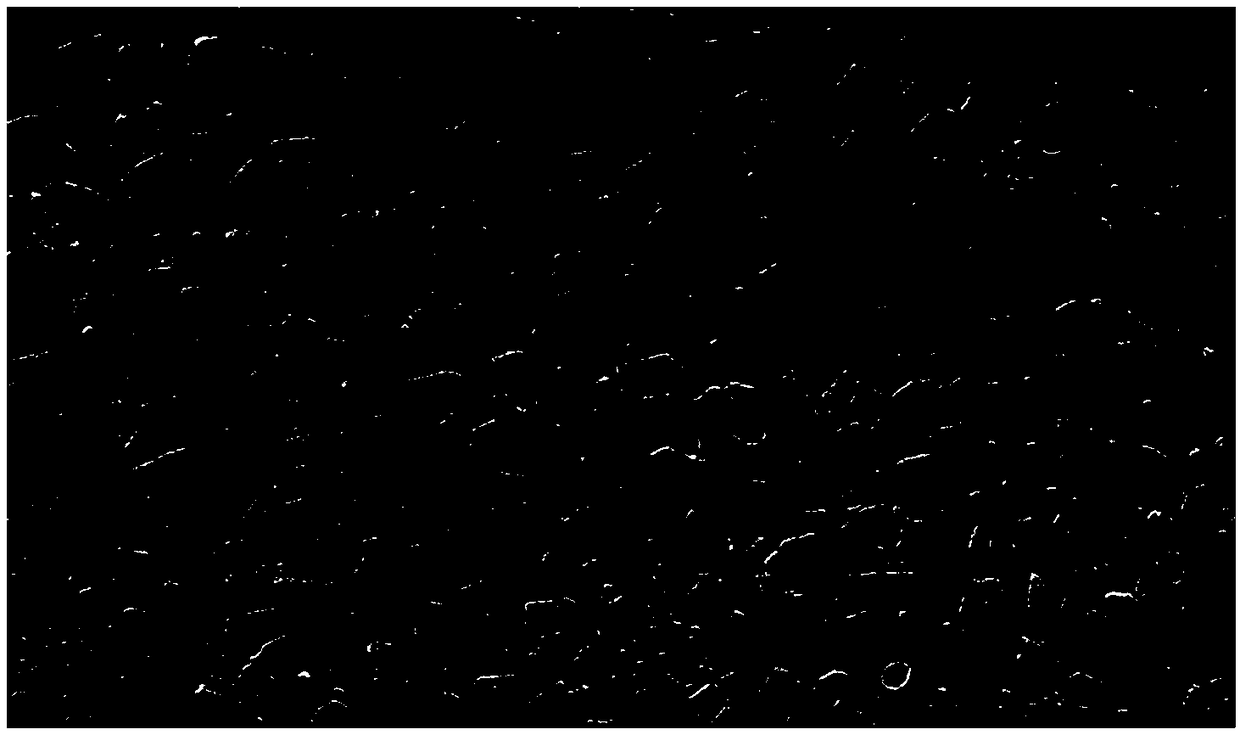

[0047] Such as figure 2 As shown in the microstructure photos, the reinforcements are evenly distributed, the structure is dense, the defects are less, and the infiltration effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com