A structure-controllable 3D reinforced aluminum matrix composite material and its preparation method

A technology of aluminum matrix composites and reinforced aluminum matrix, which is applied in the field of precision forming of high-performance aluminum matrix composites, can solve the problem of inability to accurately control the internal fiber structure shape and fiber volume fraction of 3D reinforced aluminum matrix composites, which affects the structure and structure of composite materials. It is difficult to precisely control the mechanical properties and fiber volume fraction, etc., so as to achieve the effect of precise and controllable reinforcement structure, reduce liquid infiltration resistance, realize precise forming and mass industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a method for preparing a structure-controllable 3D reinforced aluminum-based composite material, comprising the following steps:

[0027] The unidirectional fiber cloth is laid up along the fiber direction, and after being fixed, the unidirectional fiberboard is obtained;

[0028] performing liquid impregnation and compounding of the unidirectional fiberboard and the first liquid aluminum alloy along the fiber direction to obtain a unidirectional fiber-reinforced aluminum matrix composite material sheet;

[0029] Cutting the unidirectional fiber-reinforced aluminum-matrix composite material plate along the parallel fiber direction to obtain a unidirectional aluminum-matrix composite material wire;

[0030] After the unidirectional aluminum matrix composite material wires are overlapped according to the 3D structure, they are consolidated and bound to obtain a 3D reinforcement;

[0031] The 3D reinforced body is compounded with the second liquid a...

Embodiment 1

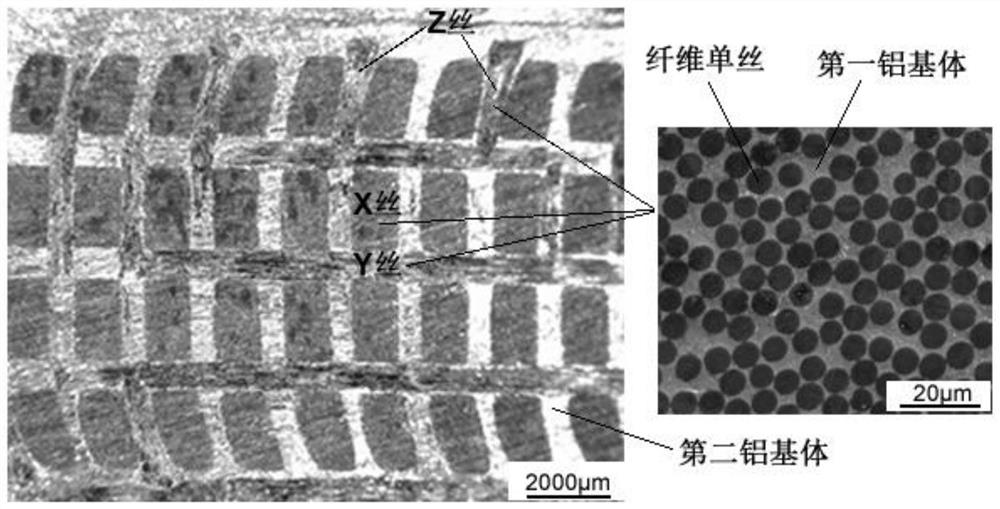

[0052] Structure-controllable graphite fiber 3D reinforced ZL301 aluminum matrix composite:

[0053] Lay up unidirectional graphite fiber (M40JB) cloth with a length of 200mm (along the direction of fiber arrangement), a width of 150mm (perpendicular to the direction of fiber arrangement), and a weight of 6.75g to a thickness of 10mm along the fiber direction, and clamp and fix it with a graphite mold to obtain the thickness 10mm unidirectional graphite fiberboard;

[0054] Preheat the unidirectional graphite fiber board to 500°C, melt 500g of ZL301 aluminum alloy at 700°C to obtain the first liquid ZL301 aluminum alloy, and use the first liquid ZL301 aluminum alloy to impregnate the single Carry out liquid state impregnation (vacuum degree is 10Pa, pressure difference is 0.46MPa) to graphite fiber plate along fiber direction, obtains unidirectional graphite fiber reinforced ZL301 aluminum matrix composite material plate (unidirectional fiber volume fraction is 60%, ZL301 volu...

Embodiment 2

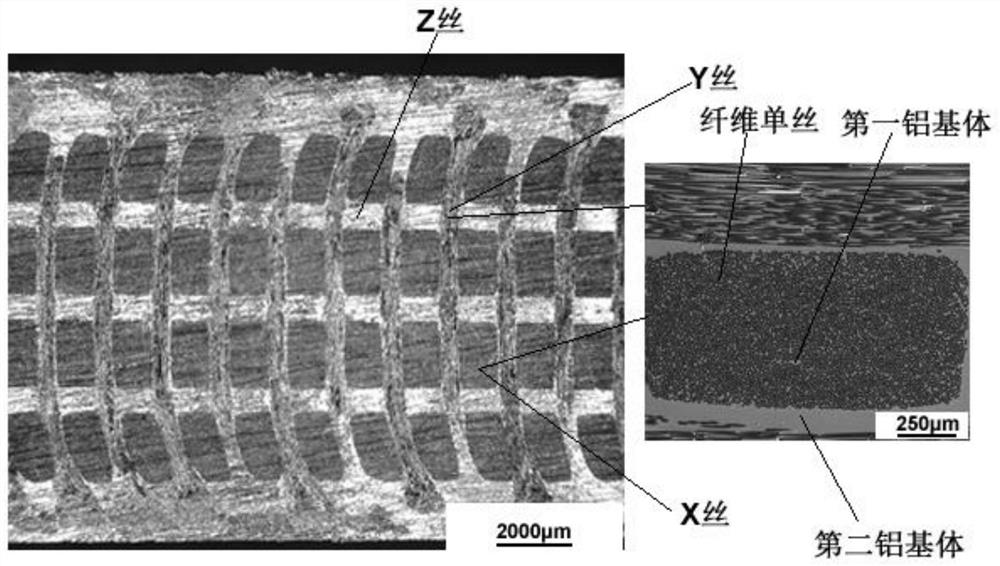

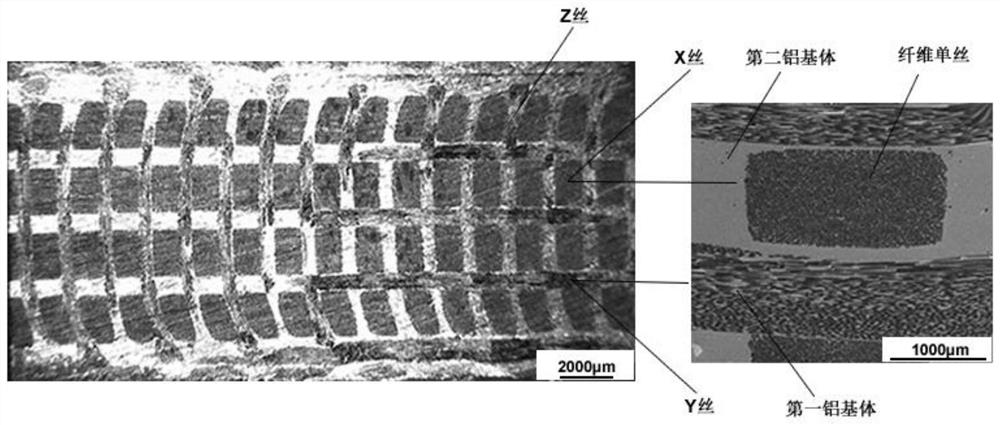

[0063] Structure controllable silicon carbide fiber 3D reinforced ZL114A aluminum matrix composite:

[0064] Lay a unidirectional Hi-Nicalon-1K silicon carbide fiber cloth with a length of 200mm (along the direction of fiber arrangement), a width of 150mm (perpendicular to the direction of fiber arrangement), and a weight of 13.50g to a thickness of 10mm along the fiber direction, and clamp it with a silicon carbide mold Fixed to obtain a unidirectional silicon carbide fiber plate with a thickness of 10mm;

[0065] Preheat the unidirectional silicon carbide fiber board to 500°C, melt 500g of ZL114A aluminum alloy at 700°C to obtain the first liquid ZL114A aluminum alloy, and use the first liquid ZL114A aluminum alloy to impregnate the The unidirectional silicon carbide fiber plate is impregnated in liquid state along the fiber direction (vacuum degree is 12Pa, pressure difference is 0.46MPa), and the unidirectional silicon carbide fiber reinforced ZL114A aluminum matrix compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com