Method integrated Preparation of extruding and impregnating composite material with parts forming and its device

A technology for composite materials and parts, which is applied in the field of integrated methods and equipment for the preparation of extrusion-impregnated composite materials and the forming of parts, can solve the problem that the performance stability and reliability of composite materials cannot be guaranteed, and it is difficult for ordinary casting methods to obtain optimal materials. The performance and microstructure do not have problems such as repeatability, so as to achieve the effect of small and uniform microstructure, which is conducive to precision forming and low pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

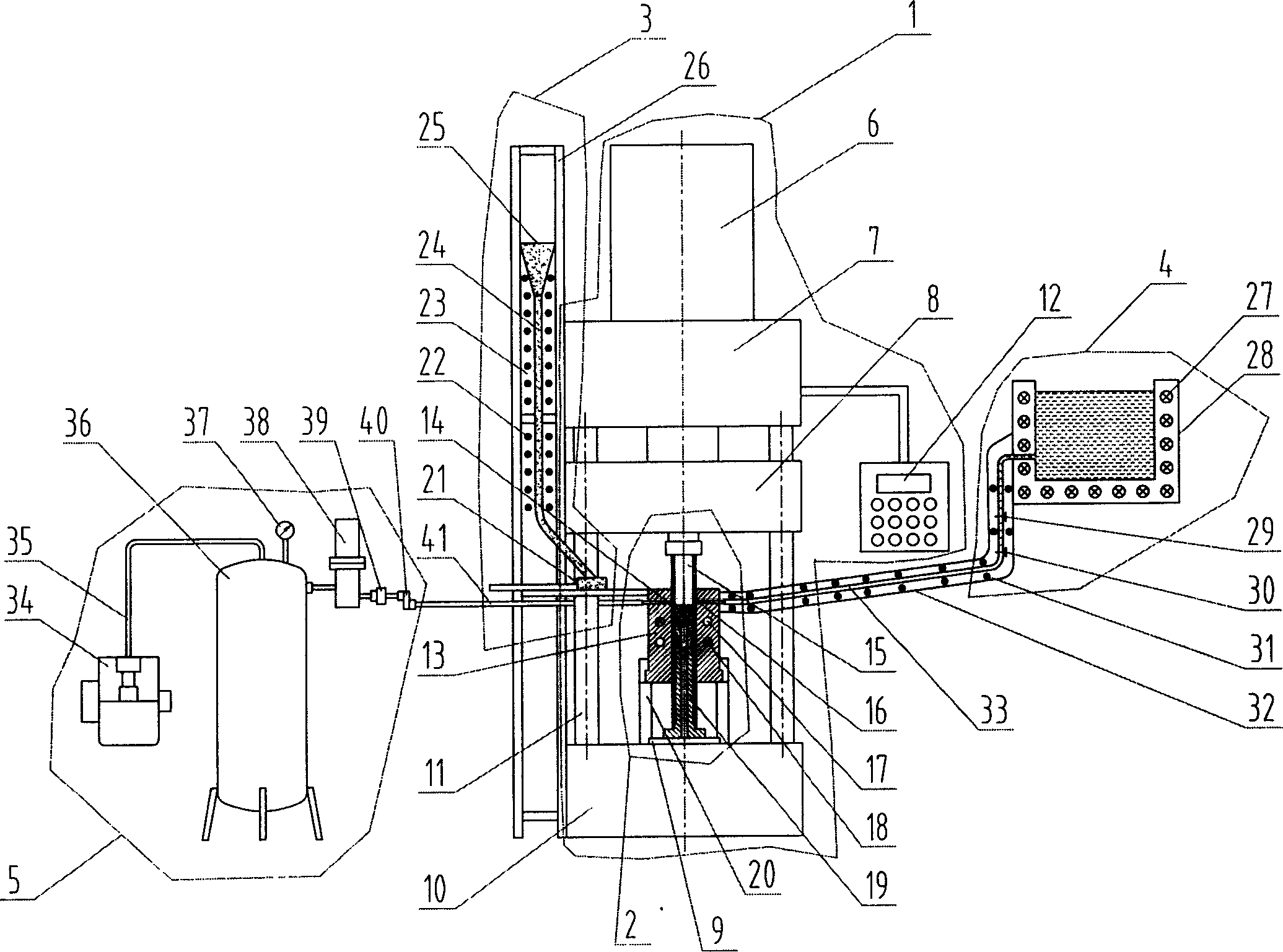

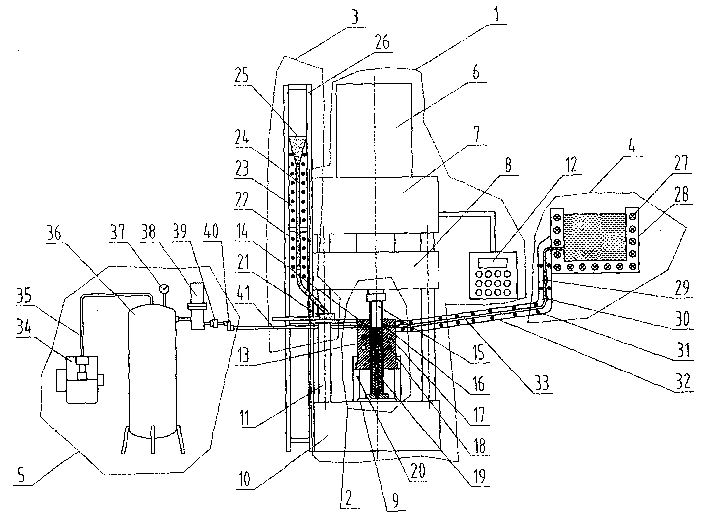

[0024] Such as figure 1 As shown, the integrated equipment for the preparation of extrusion-impregnated composite materials and parts forming according to the present invention is formed by interconnecting a press 1, a mold 2, a powder feeding device 3, a liquid supply device 4, and a vacuum pumping device 5. Wherein, the mold 2 is installed on the lower beam 10 workbench of the press 1, the liquid supply device 4 communicates with the mold cavity of the mold 2 through the pipeline, and the vacuum device 5 also communicates with the mold cavity of the mold 2 through the pipeline, and the powder feeding The device 3 is connected to the mold cavity of the mold 2 . Wherein, the press 1 is composed of an upper cylinder 6 , an upper beam 7 , a movable beam 8 , a lower cylinder 9 , a lower beam 10 , a guide column 11 and an operation control panel 12 . Mold 2 is made up of gear female mold 13, vacuum control valve 14, upper gear male mold 15, liquid input control valve 16, cooling ...

Embodiment 2

[0028] The process of this embodiment is basically the same as that of Example 1, except that the powder material is mixed with silicon dioxide powder with an average particle size of 50 μm and a silicon dioxide powder with an average particle size of 10 μm in a mass ratio of 6:4; After the boot 21 leaves the mouth of the gear female mold 13, the lower gear male mold 19 descends for a certain distance, and then the upper gear male mold 15 descends, so that the lower surface of the upper gear male mold 15 is formed with the inner wall of the gear female mold 13 and the upper surface of the lower gear male mold 19. an enclosed space.

[0029] When the shape of the part is complicated and the powder cannot be evenly filled in the mold cavity through the powder feeding shoe 21, the powder conveying hose 24 can be connected to the material input port of the mold 2, and the powder conveying hose 24 can be driven together by vibrating the mold 2 Vibration makes the powder enter the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com