Industrial sizing device for carbon fibers

A carbon fiber and sizing technology, which is applied in the processing of textile material equipment configuration, textile and papermaking, and textile material processing, etc., to achieve the effects of high sizing efficiency, no waste sizing agent discharge, and fast and convenient positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

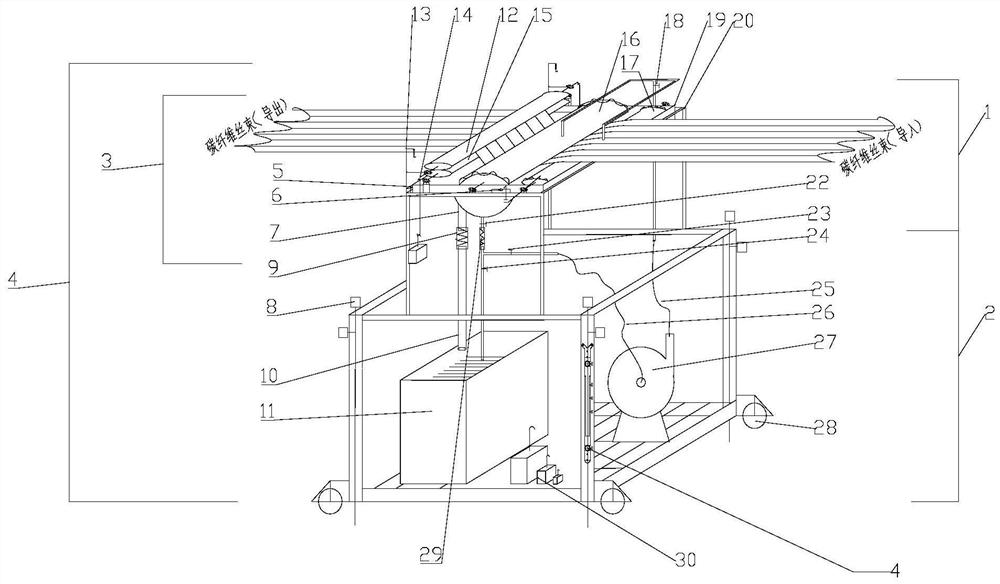

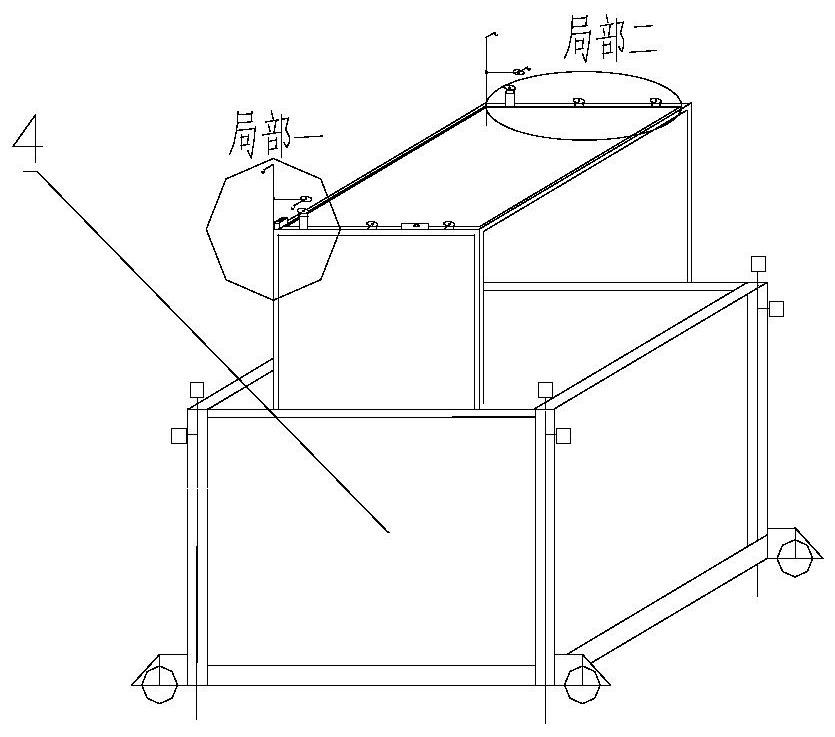

[0040] Carbon fiber industrialized sizing device provided by the invention, such as figure 1 As shown, its composition includes: Sizing system 1, slurry supply system 2, slurry control system 3, base frame system 4 consists of four parts,

[0041] The sizing system 1 is located at the upper part of the device; the sizing agent storage tank and the circulating feed pump of the sizing system 2 are located directly below the sizing system 1, and the slurry control system 3 is located at the upper left of the sizing system 1 The lower part of the base frame system 4 accommodates the slurry supply system 2, and the upper part of the base frame system 4 supports the slurry supply system 2 and the slurry control system 3, which are at the bottom of the above three systems and peripheral;

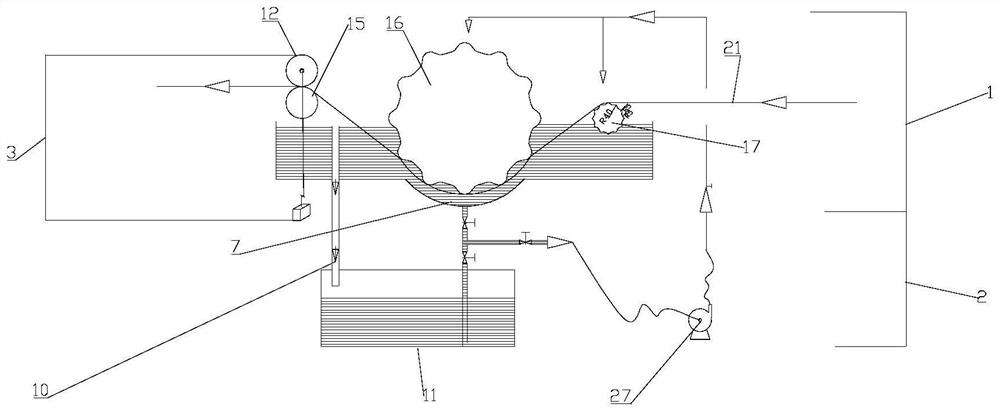

[0042] For the sizing system 1, see figure 2 , consisting of a sizing agent feed pipe 20, a star-shaped guide roller 17, a star-shaped sizing roller 16, an X-axis level 5 and a Y-axis level 6, a...

Embodiment 2

[0056] Adopt carbon fiber industrialization sizing device provided by the invention and use method (as figure 1 ), for the convenience of device operation and effect comparison, 3% PU sizing is carried out with 8 bundles of carbon fibers 21, and the implementation process is as in the embodiment implementation process 1---7. Get 8 bundles of finished carbon fiber tows; test the tow width / hair, sizing rate deviation (CV), strength deviation (CV), unwinding property, and mesh performance of carbon fibers. The results are shown in Table 1 for comparison of effects.

Embodiment 3

[0058] Adopt carbon fiber industrialization sizing device provided by the invention and use method (as figure 1 ), for the convenience of device operation and effect comparison, 6% PU sizing is carried out with 8 bundles of carbon fibers 21, and the implementation process is as in the embodiment implementation process 1---7. Get 8 bundles of finished carbon fiber tows, and test the tow width / hair, sizing rate deviation (CV), strength deviation (CV) unwinding property, and mesh performance of two kinds of carbon fibers. The results are shown in Table 1 for comparison of effects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com