Mg alloy/Al2O3 composite and preparation method thereof

A composite material and alloy technology, which is applied in the field of Mg alloy/Al2O3 composite material and its preparation, can solve the problems of inability to achieve metal and ceramic wetting, serious alloy powdering, and inappropriate use of nitrogen-containing atmosphere.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

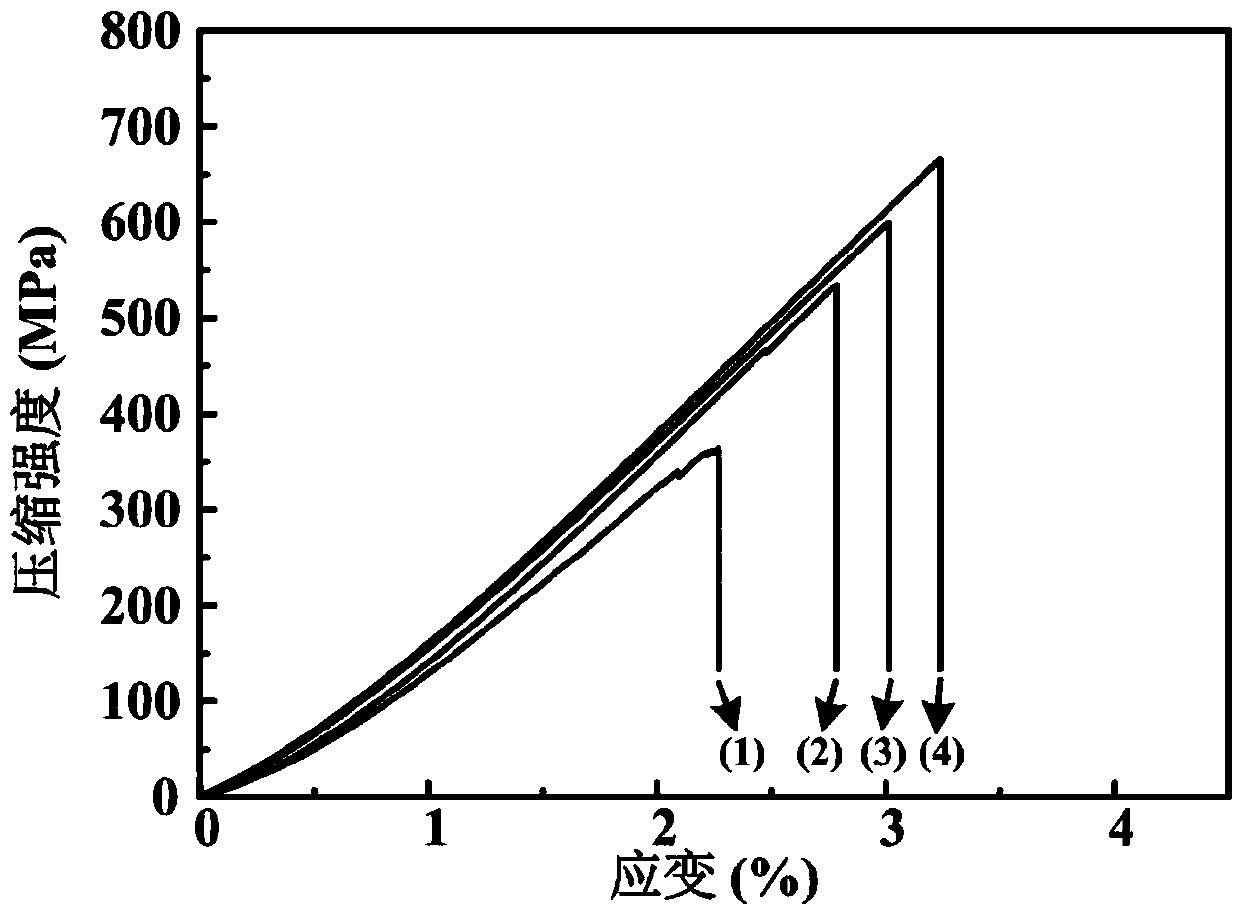

Examples

Embodiment Construction

[0023] The present invention is described in further detail below by enumerating the embodiment.

[0024] Mg alloy / Al of the present invention 2 o 3 Preparation of composite materials:

[0025] 1. Water-based Al 2 o 3 Preparation of slurry

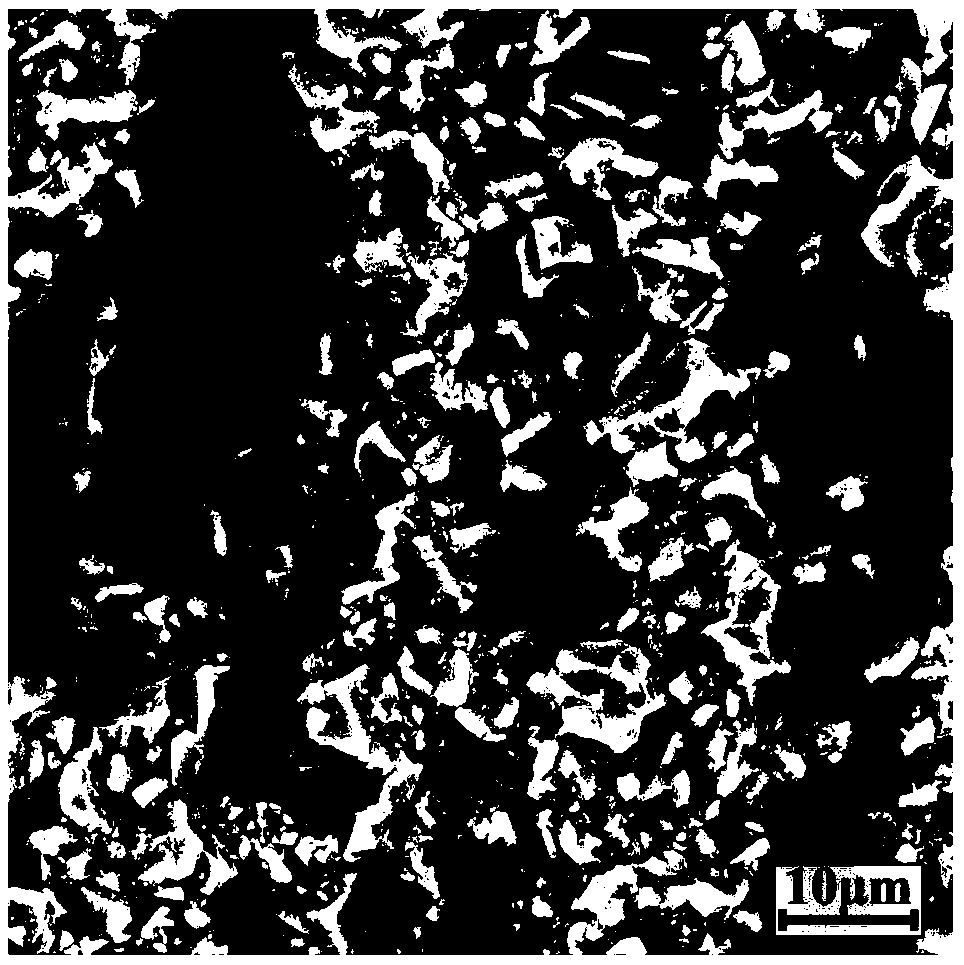

[0026] Dissolve the dispersant sodium polymethacrylate in the aqueous solution at 40°C, and then mix with Al 2 o 3 Powders were mixed and milled for 6 hours with a planetary ball mill at a speed of 100r / min to make a ceramic slurry, in which Al 2 o 3 The volume percentage of powder in the whole slurry is 10-40vol.%, and the content of dispersant is Al 2 o 3 1wt.% of the powder, the slurry after ball milling was vacuum stirred and degassed for 20 minutes, the stirring speed was 80-100r / min, and the water-based Al with a particle size of less than 5μm was obtained 2 o 3 slurry.

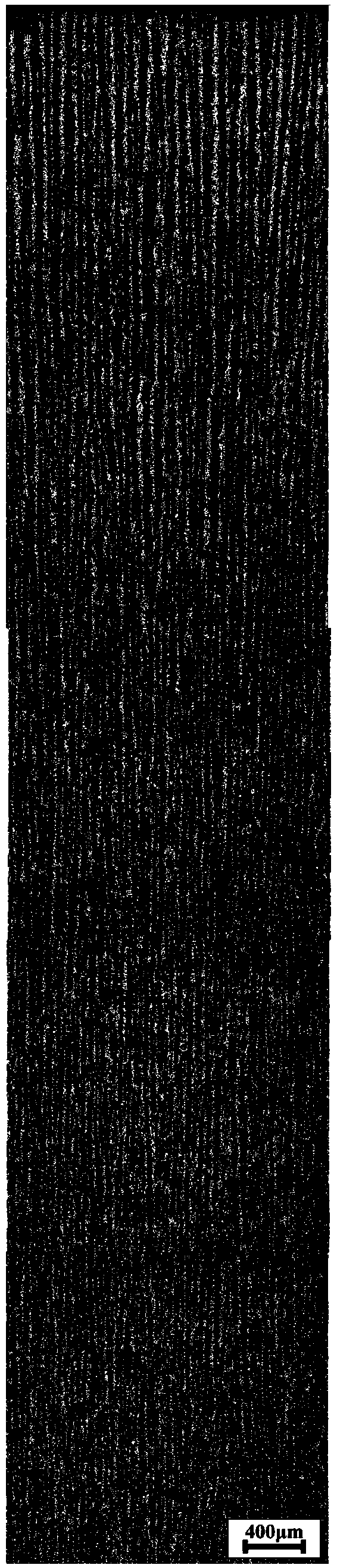

[0027] 2. Directional solidification

[0028] Put the above water-based Al 2 o 3 The slurry is poured into a polytetrafluoroethylene mold, and direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com