Preparation method of silica airgel composite material reinforced by silicon carbide fiber mat

A technology of silicon carbide fiber and silicon dioxide, which is applied in the field of preparation of silicon dioxide airgel composite materials, can solve the problems of poor high-temperature oxidation resistance, easy aging, and poor high-temperature resistance, and achieve fast impregnation speed and large pores High efficiency and good hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

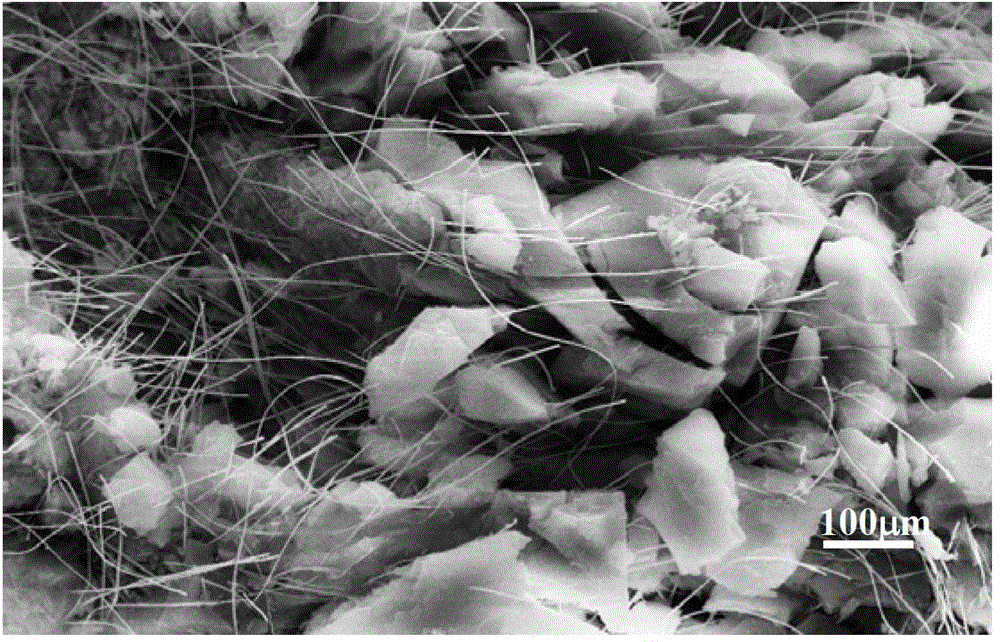

[0018] Mixed solvents of xylene, tetrahydrofuran and dimethylformamide were prepared at a volume ratio of 3:1:1. A polyaluminocarbosilane spinning solution with a concentration of 0.9 g / mL was prepared. The spinning solution was electrospun under the conditions of output voltage of 18kV, injection flow rate of 2.0mL / h, and receiving distance of 8cm to obtain the precursor silicon-containing polymer micro-nano fiber mat. Then dry at 50° C. for 2 hours, oxidize and crosslink in an air atmosphere at 200° C. for 3 hours, and perform heat treatment at 1000° C. in an inert atmosphere to obtain a silicon carbide micro-nano ceramic fiber mat.

[0019] Mix tetraethyl orthosilicate: ethanol: water in a stirring tank at a molar ratio of 1:8:3, add dropwise hydrochloric acid with a concentration of 0.01mol / L, adjust the pH to 3.5, and stir for 1 h at the same time; then, under stirring conditions The pH of the system was adjusted to 7.8 with ammonia water at a concentration of 0.01 mol / L...

Embodiment 2

[0022] Mixed solvents of xylene, tetrahydrofuran and dimethylformamide were prepared at a volume ratio of 3:1:1. A polyaluminocarbosilane spinning solution with a concentration of 1.1 g / mL was prepared. The spinning solution was electrospun under the conditions of output voltage of 22kV, injection flow rate of 1.5mL / h, and receiving distance of 12cm to obtain the precursor silicon-containing polymer micro-nano fiber mat. Then dry at 50°C for 2 hours, oxidize and crosslink in an air atmosphere at 200°C for 3 hours, and perform heat treatment at 1200°C in an inert atmosphere to obtain a silicon carbide micro-nano ceramic fiber mat.

[0023] Mix tetraethyl orthosilicate: ethanol: water in a stirring tank at a molar ratio of 1:7:3, add dropwise nitric acid with a concentration of 0.01mol / L, adjust the pH to 4.5, and stir for 1 h at the same time; then, under stirring conditions The pH of the system was adjusted to 7.9 with ammonia water at a concentration of 0.01 mol / L, and a sil...

Embodiment 3

[0026] Mixed solvents of xylene, tetrahydrofuran and dimethylformamide were prepared at a volume ratio of 3:1:1. A polyaluminocarbosilane spinning solution with a concentration of 1 g / mL was prepared. The spinning solution was electrospun under the conditions of an output voltage of 20kV, an injection flow rate of 2mL / h, and a receiving distance of 10cm to obtain a precursor silicon-containing polymer micro-nano fiber mat. Then dry at 50° C. for 2 hours, oxidize and crosslink in an air atmosphere at 200° C. for 3 hours, and perform heat treatment at 1000° C. in an inert atmosphere to obtain a silicon carbide micro-nano ceramic fiber mat.

[0027]Mix tetraethyl orthosilicate: ethanol: water in a stirring tank at a molar ratio of 1:6:3, add nitric acid with a concentration of 0.01mol / L dropwise, adjust the pH to 4.6, and stir for 1 h at the same time; then, under stirring conditions The pH of the system was adjusted to 7.7 with ammonia water at a concentration of 0.01 mol / L, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com