Stainless steel liquid polishing paste and preparation method thereof

A stainless steel and polishing wax technology, applied in the field of surface treatment, can solve the problems of insufficient surface gloss and difficult cleaning, and achieve the effects of high gloss, simple cleaning and reduced uncertainty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

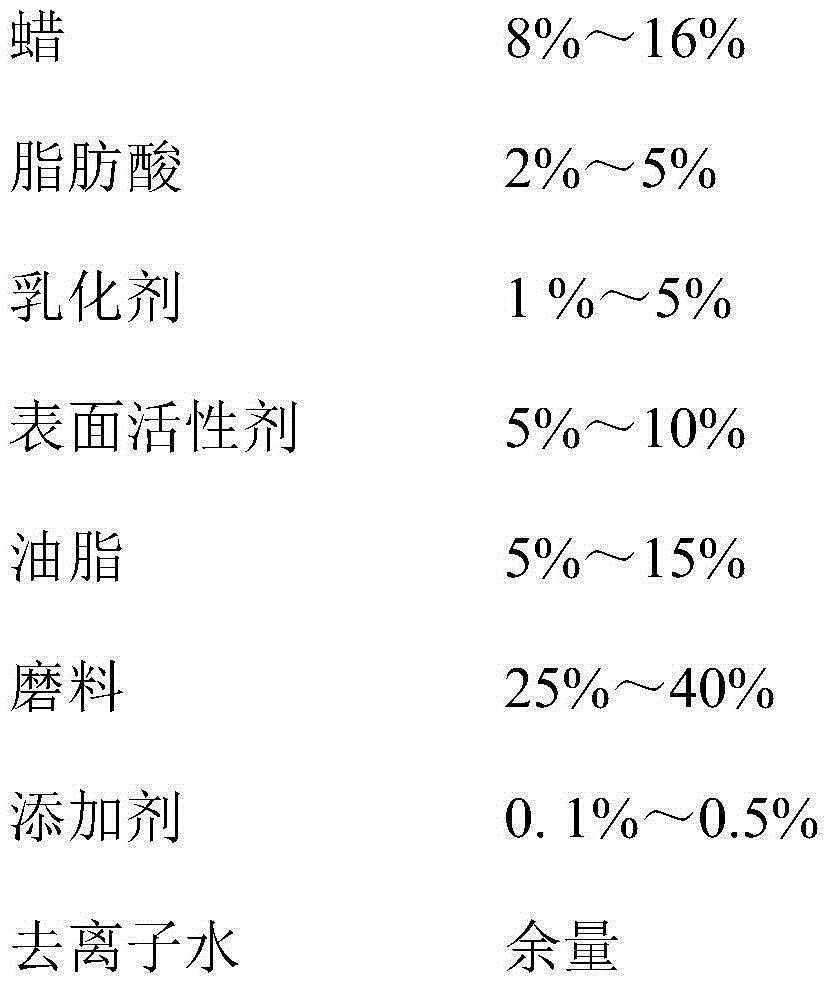

[0033] Embodiment 1, a kind of stainless steel liquid polishing wax, comprise the raw material component of following mass percent:

[0034]

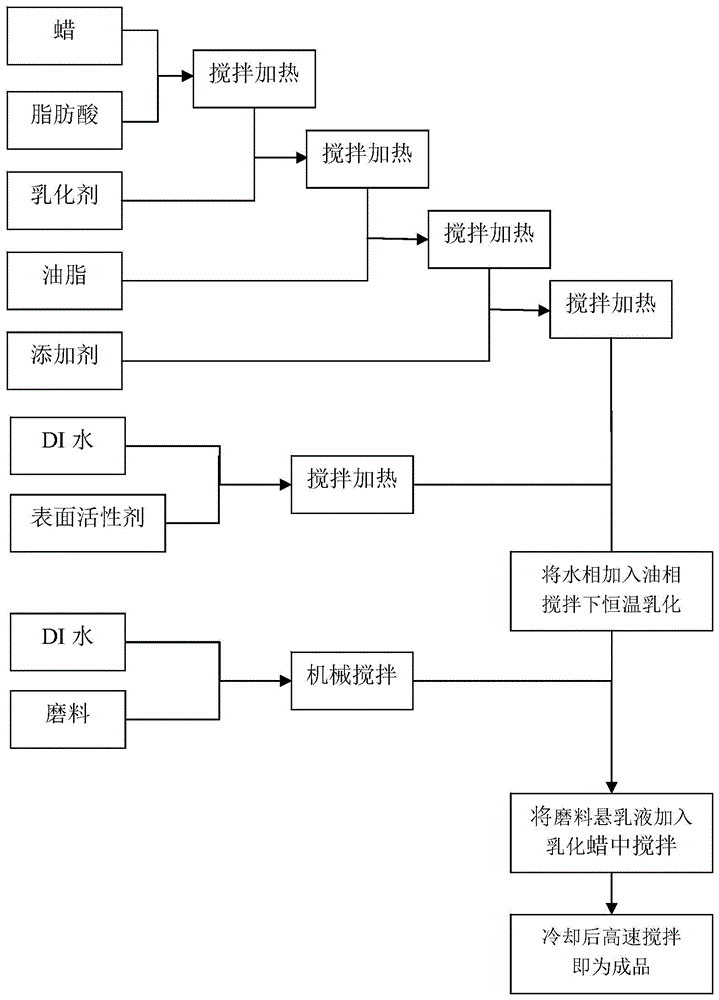

[0035] Preparation methods such as figure 1 shown, including the following steps:

[0036] A. Under stirring, add the raw material wax, fatty acid, emulsifier, oil, and additives into a constant temperature container at 80°C in sequence. Specifically: firstly add the raw material wax and fatty acid to a constant temperature container, stir to make the wax and fatty acid mix evenly, then add emulsifier and continue heating and stirring until well mixed, then add oil and heat and stir well, finally add additives, heat and stir well, stir until all dissolved to obtain a mixed solution;

[0037] B. Add the surfactant and deionized water into another 80°C constant temperature container, stir until completely dissolved, and obtain a surfactant solution;

[0038] C. Add deionized water to the abrasive, and stir evenly to prepare an abras...

Embodiment 2

[0041] Embodiment 2, a kind of stainless steel liquid polishing wax, comprise the raw material component of following mass percentage:

[0042]

[0043] Preparation methods such as figure 1 shown, including the following steps:

[0044]A. Under stirring, add the raw material wax, fatty acid, emulsifier, oil, and additives into a constant temperature container at 90°C in sequence. Specifically: firstly add the raw material wax and fatty acid to a constant temperature container, stir to make the wax and fatty acid mix evenly, then add emulsifier and continue heating and stirring until well mixed, then add oil and heat and stir well, finally add additives, heat and stir well, stir until all dissolved to obtain a mixed solution;

[0045] B. Add the surfactant and deionized water into another 90°C constant temperature container, stir until completely dissolved, and obtain a surfactant solution;

[0046] C. Add deionized water to the abrasive, and stir evenly to prepare an abr...

Embodiment 3

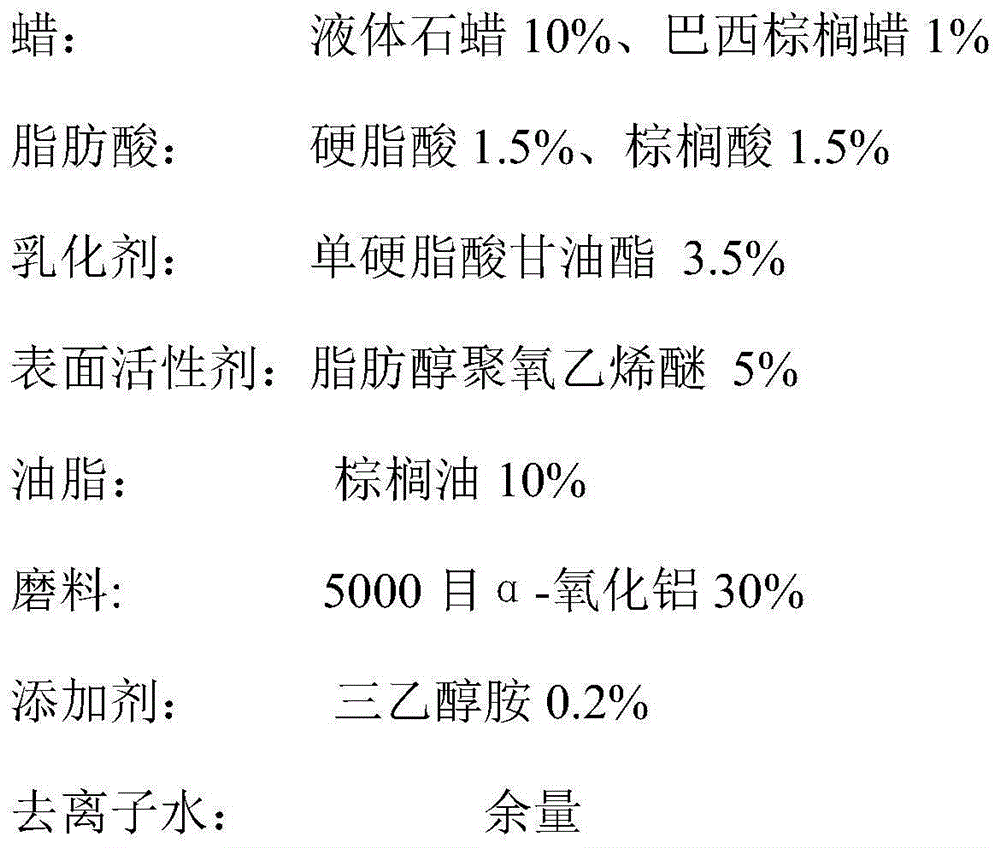

[0049] Embodiment 3, a kind of stainless steel liquid polishing wax, comprise the raw material component of following mass percentage:

[0050]

[0051] Preparation methods such as figure 1 shown, including the following steps:

[0052] A. Under stirring, add the raw material wax, fatty acid, emulsifier, oil, and additives into a constant temperature container at 85°C in sequence. Specifically: firstly add the raw material wax and fatty acid to a constant temperature container, stir to make the wax and fatty acid mix evenly, then add emulsifier and continue heating and stirring until well mixed, then add oil and heat and stir well, finally add additives, heat and stir well, stir until all dissolved to obtain a mixed solution;

[0053] B. Add the surfactant and deionized water into another 85°C constant temperature container, and stir until completely dissolved to obtain a surfactant solution;

[0054] C. Add deionized water to the abrasive, and stir evenly to prepare an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com