Fibre reinforced resin based composite material fin piece molding mould

A fiber-reinforced resin and composite material technology is applied in the field of forming molds for composite fins. The effect of good quality and reduced product porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

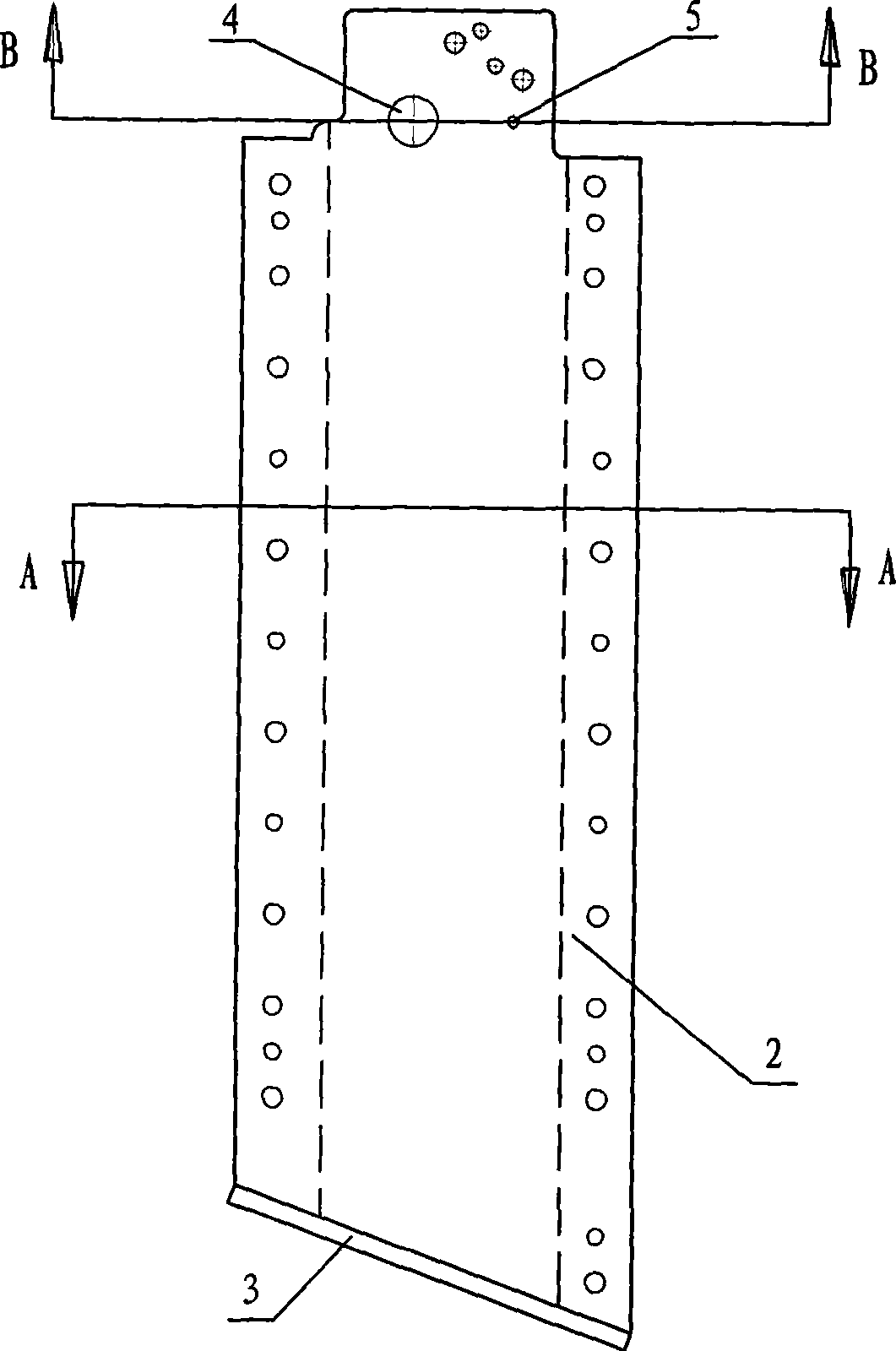

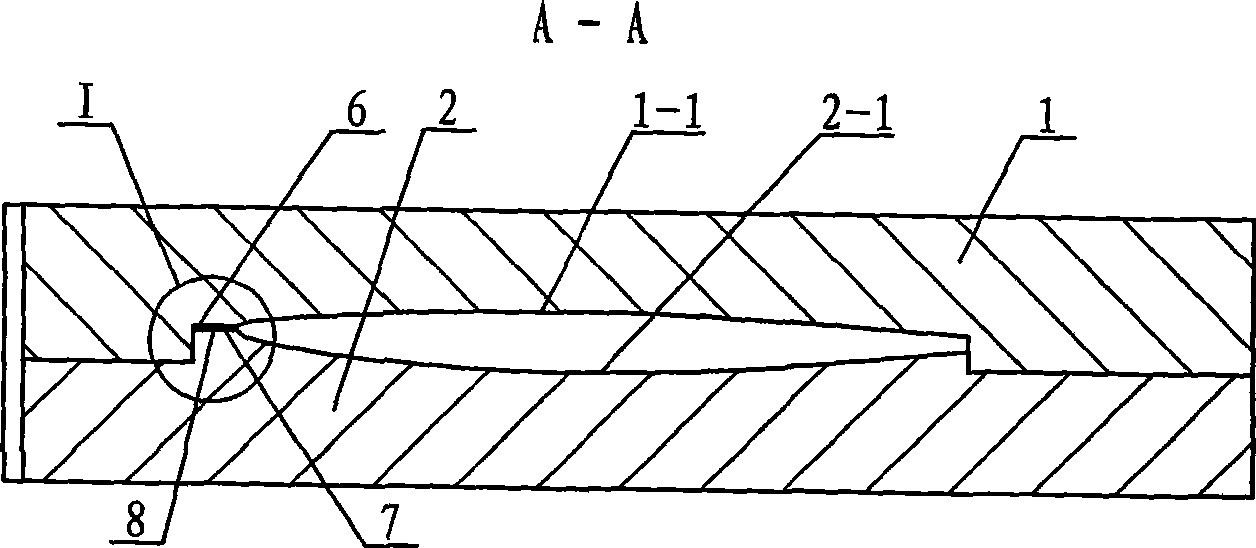

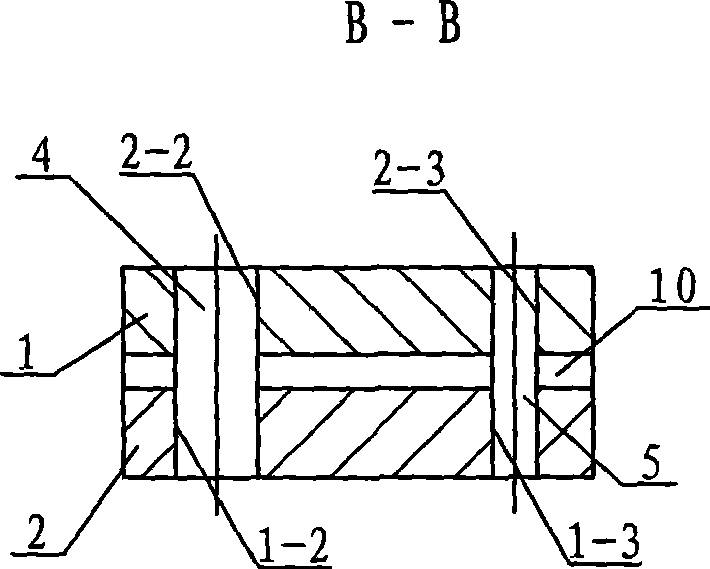

[0007] Specific implementation mode one: combine Figure 1 ~ Figure 4 Describe this embodiment, this embodiment includes upper mold 1, lower mold 2, limit plate 3, first positioning pin 4 and second positioning pin 5, the parting surface 6 of upper mold 1 and lower mold 2 is provided with upper Model groove 1-1, the parting surface 7 of lower mold 2 and upper mold 1 is provided with lower mold groove 2-1, a cavity is formed between upper mold groove 1-1 and lower mold groove 2-1, and a limit plate 3 Installed on the bottom slope of the upper die 1 and the lower die 2, the upper end of the upper die 1 is provided with a first positioning pin hole 1-2 and the second positioning pin hole 1-3, and the upper end of the lower die 2 is provided with a second Three positioning pin holes 2-2 and the fourth positioning pin hole 2-3, the first positioning pin 4 is arranged in the first positioning pin hole 1-2 and the third positioning pin hole 2-2, the second positioning pin 5 is arrang...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination Figure 4 The present embodiment will be described. The width W of the overflow groove 8 of the present embodiment is 15 to 25 mm, and the depth h of the overflow groove 8 is 0.3 to 0.5 mm. The overflow groove 8 within the above numerical range can not only achieve the function of exhausting and discharging excess resin, but also does not affect the mechanical properties and appearance quality of the product. Other combinations and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination Figure 4 The present embodiment will be described. The width W of the overflow groove 8 of the present embodiment is 20 mm. This width is sufficient to ensure that the overflow tank 8 is exhausted and excess resin is discharged. Other combinations and connections are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com