Dumping and sintering process for 3D printing ceramic body

A ceramic body, 3D printing technology, applied in the field of additive manufacturing, can solve the problems of uneven composition, complex origin of clay minerals, plasticity, thixotropic bonding, shrinkage and refractory differences, etc., and achieve uniform dimensional shrinkage. , The effect of good surface quality and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

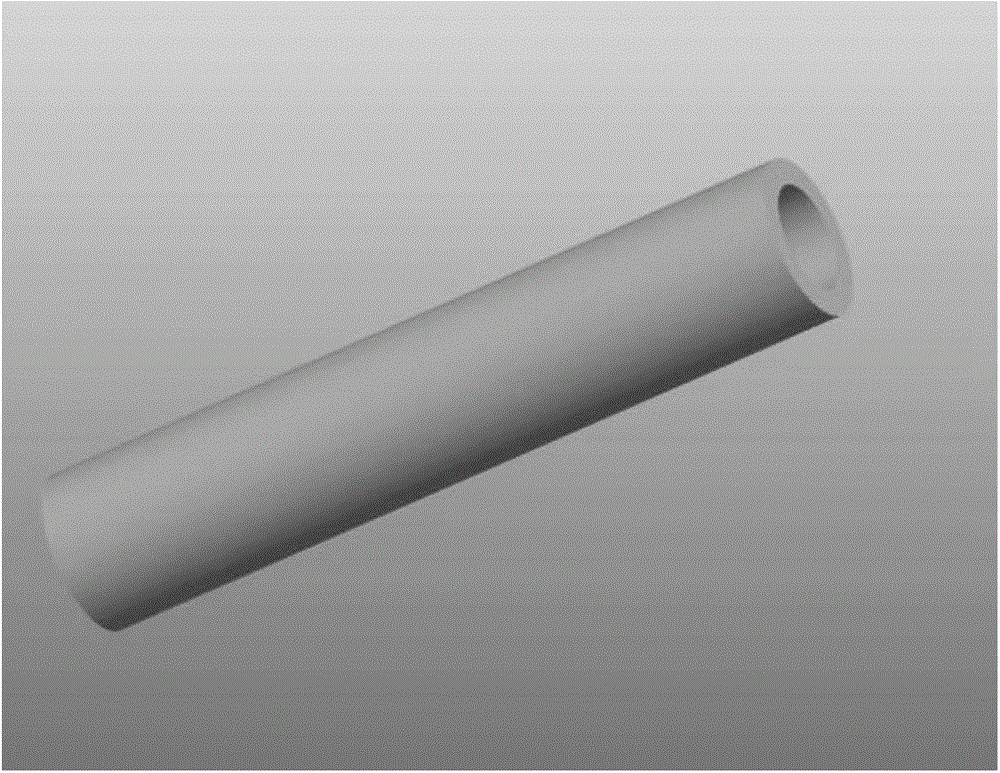

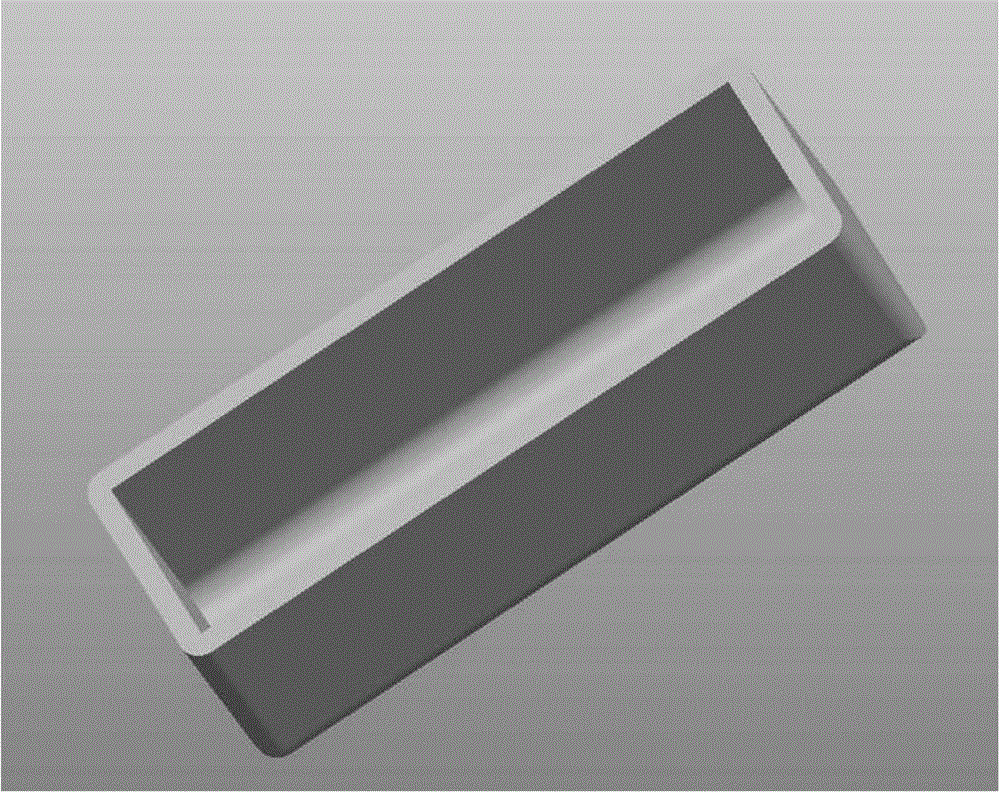

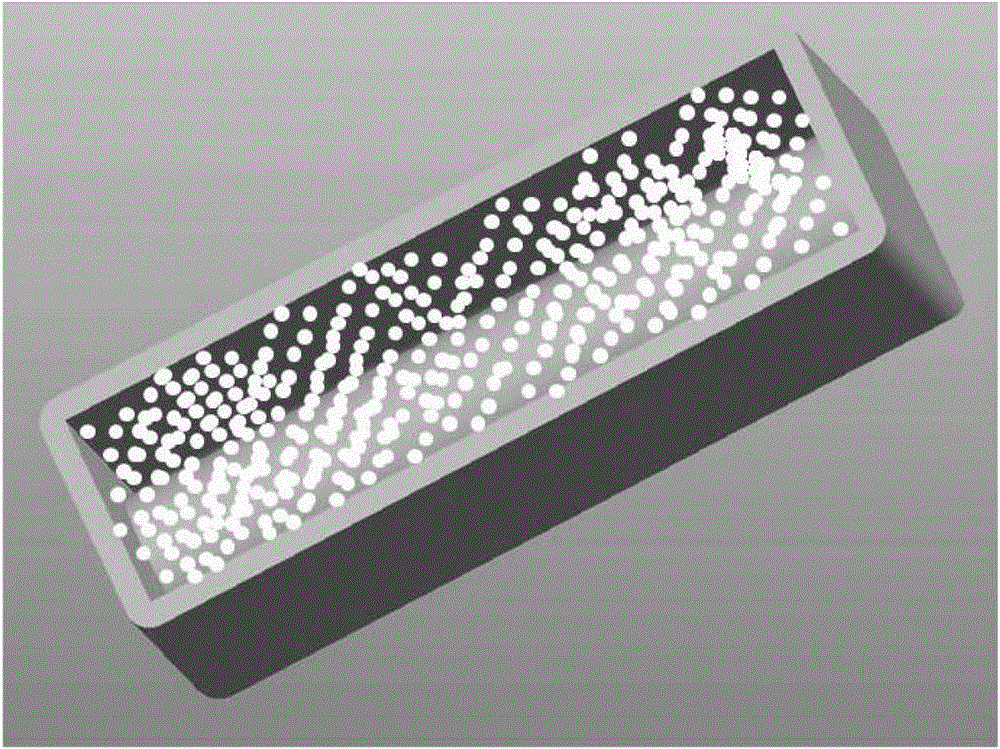

[0031] Using three-dimensional light curing technology to print alumina ceramic tube, the solid content of the ceramic body is 60%, the size of the ceramic tube is 12mm in outer diameter, 8mm in inner diameter, and 60mm in length. Figure 1a Shown. Choose amorphous alumina powder and place it in a boat-shaped alumina crucible (such as Figure 1b (Shown) spread a layer of alumina powder on the bottom, then put the ceramic tube body into the crucible, fill the ceramic tube with alumina powder, and then bury the ceramic tube body in the alumina powder, such as figure 2 Shown. Put the boat-shaped alumina crucible into the muffle furnace, close to the position of the furnace thermocouple. The temperature is raised to 200°C in 7 hours, and the temperature is raised to 500°C in 10 hours, and the temperature is kept at 500°C for 1 hour. The temperature is raised to 1100°C in 20 hours and the temperature is kept for 4 hours. After cooling to room temperature, take out the crucible, cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com