Inclined sealing ring flow distribution mechanism, axial plunger motor and axial plunger pump

An axial piston motor and sealing ring technology, which is applied to the components of pumping devices for elastic fluids, pumps, multi-cylinder pumps, etc. The effect of wear, leakage and heat reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

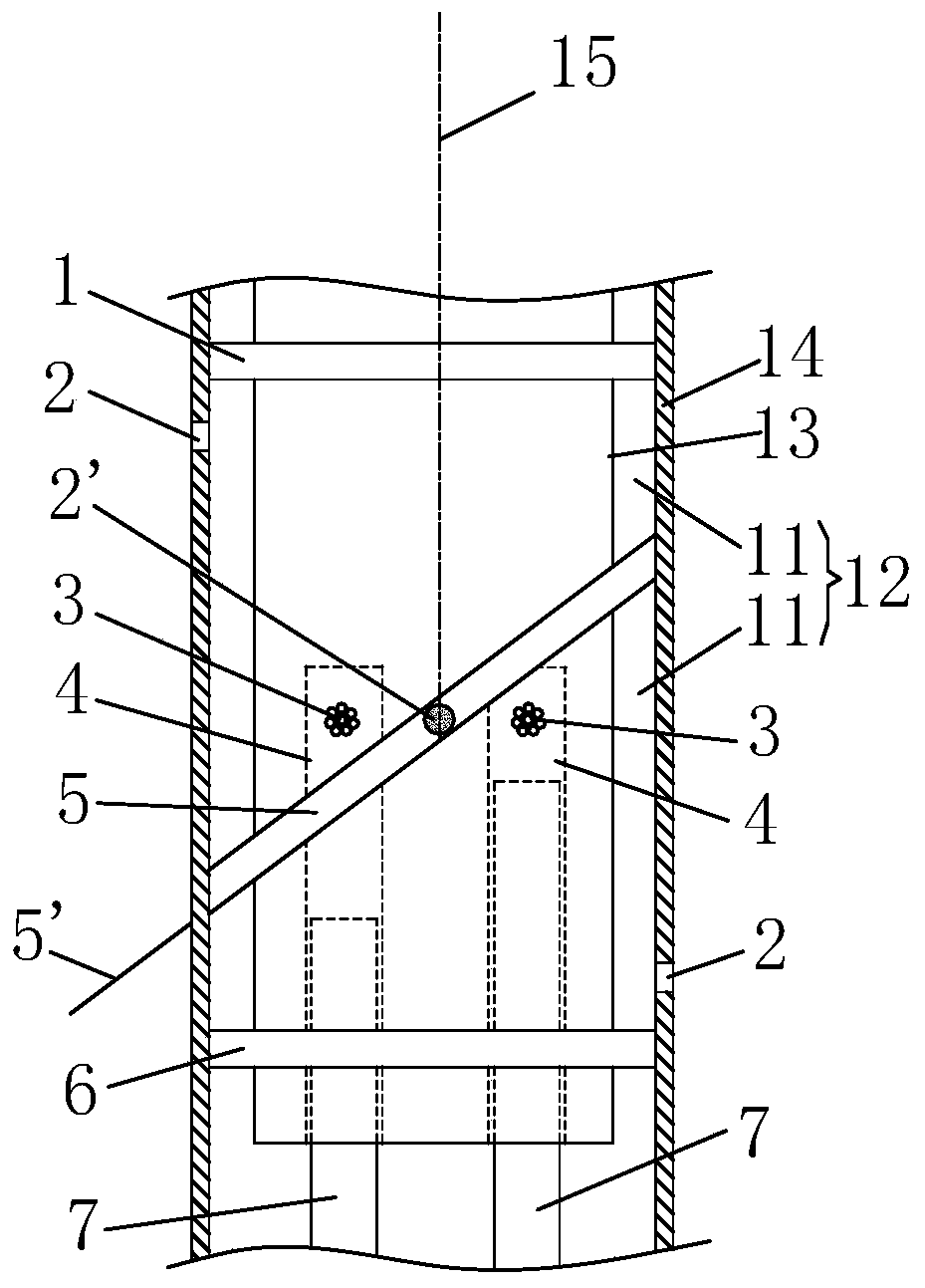

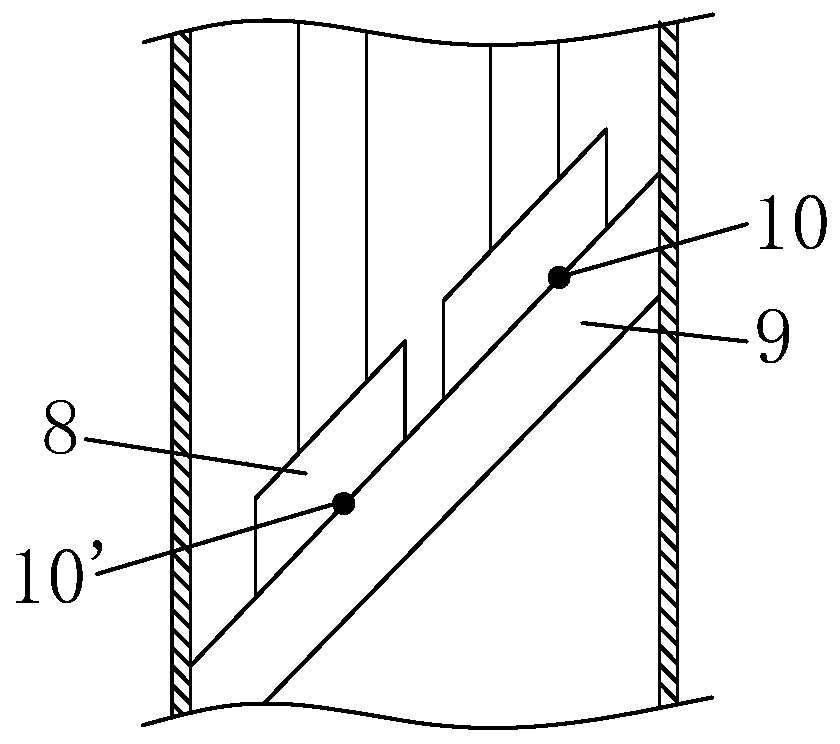

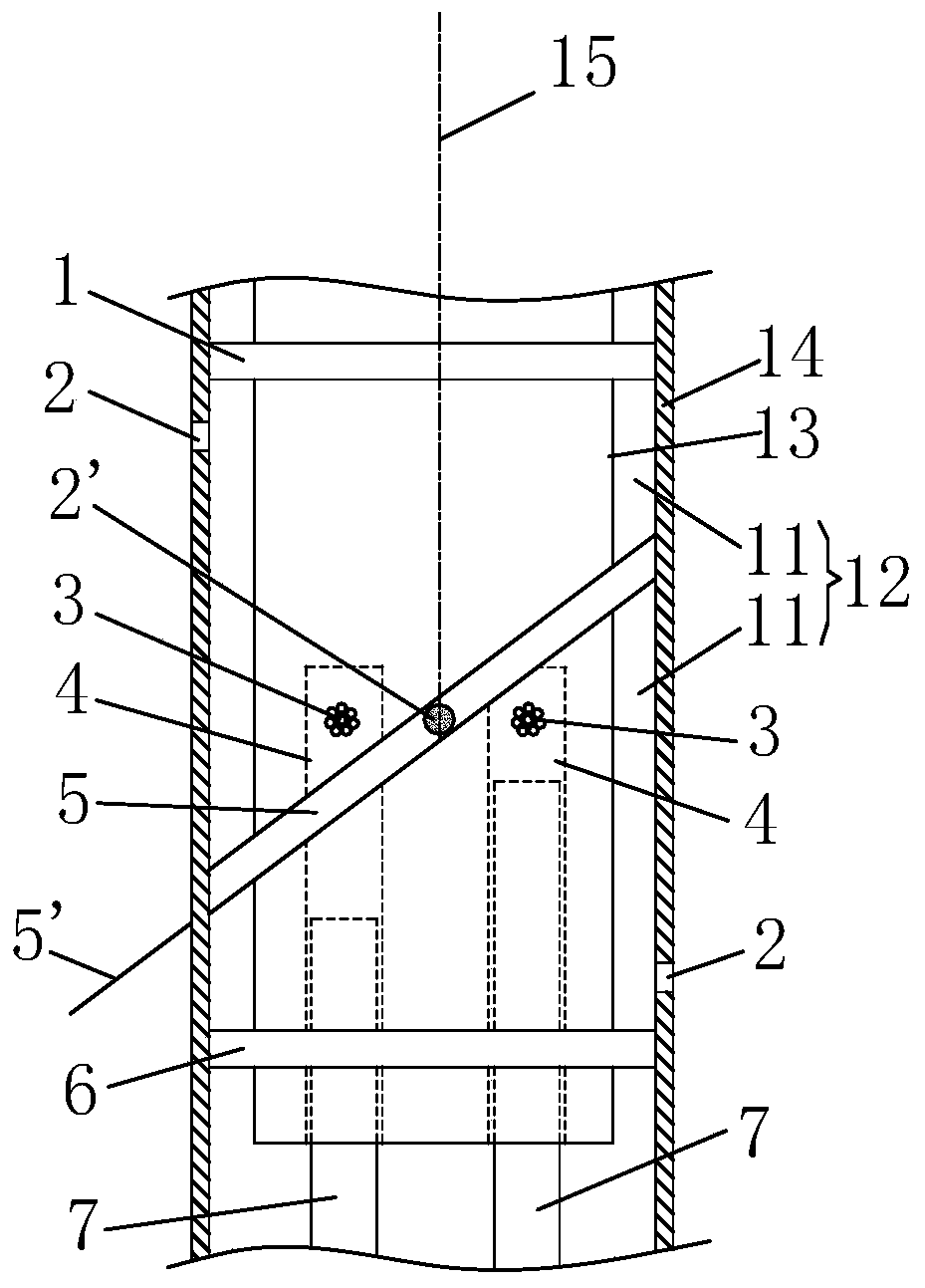

[0022] figure 1 Shown is the state after the shell is cut along the axis, figure 1 Only two plungers 7 are schematically drawn in , and actually there are more plungers. Please refer to figure 1 , the inclined seal ring flow distribution mechanism includes a first seal ring 1, a second seal ring 5 and a third seal ring 6, and the first seal ring 1, the second seal ring 5 and the third seal ring 6 are arranged at intervals The inner wall of the casing 14 of the axial piston motor forms a friction pair with the side wall of the plunger cylinder 13 of the axial piston motor, and the second sealing ring 5 connects the side wall of the piston cylinder 13 and the The annular space 12 between the casings 14 is separated to form two working fluid areas 11, and the plane 5' where the second sealing ring 5 is located is oblique to the rotation axis 15 of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com