Inner hole toothing device for flexible strips

A strip and soft technology, applied in the field of machinery, can solve problems such as low production efficiency, unreasonable structure, and matching of teething speed and speed, and achieve the effects of improving operating efficiency, strong adaptability, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

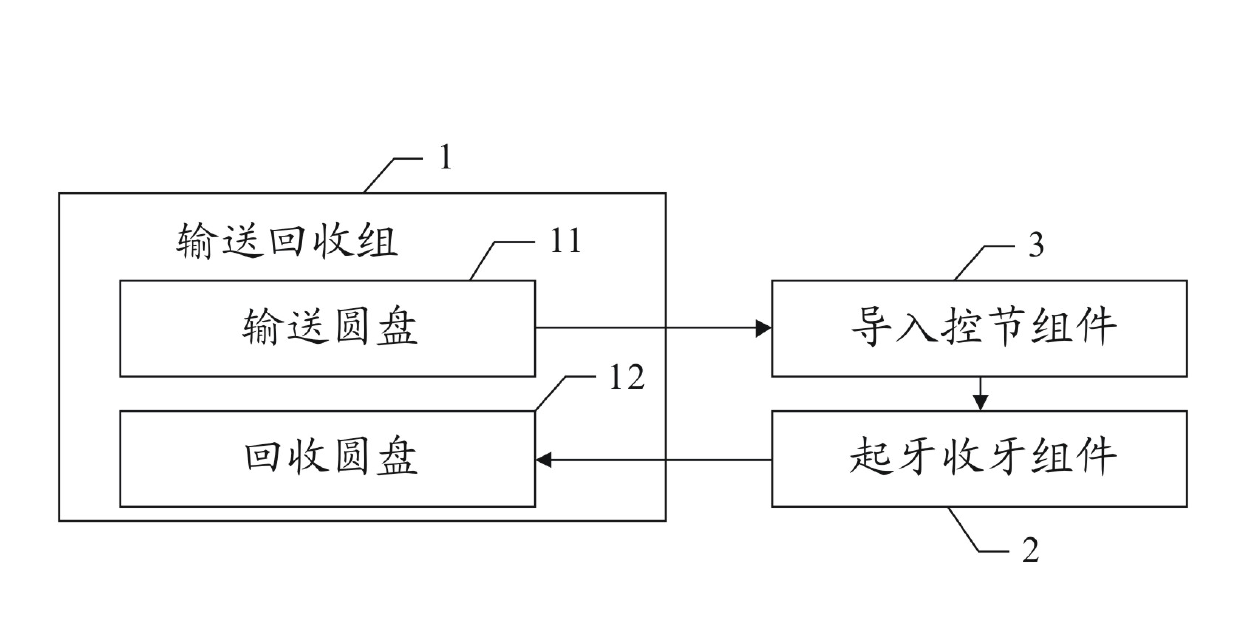

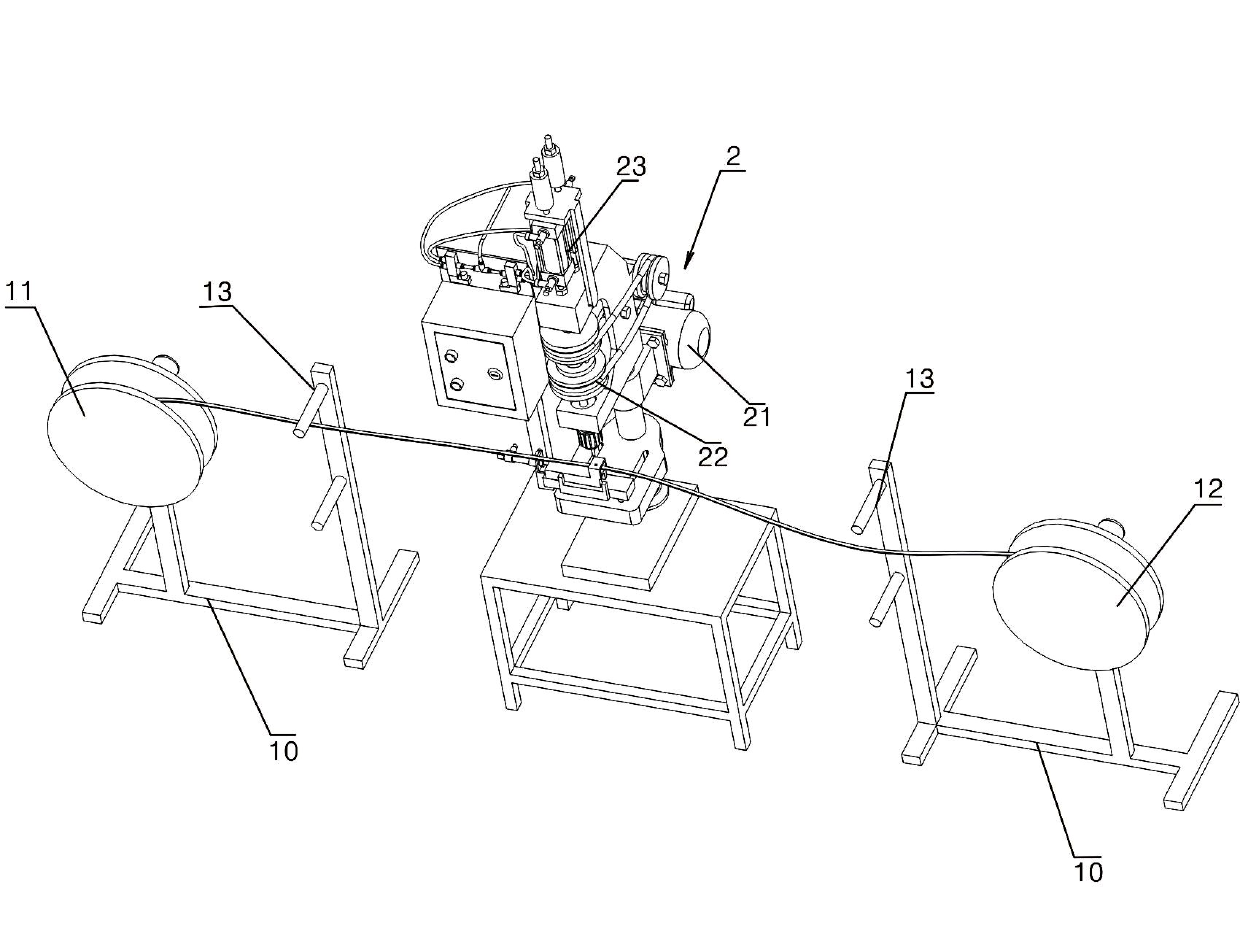

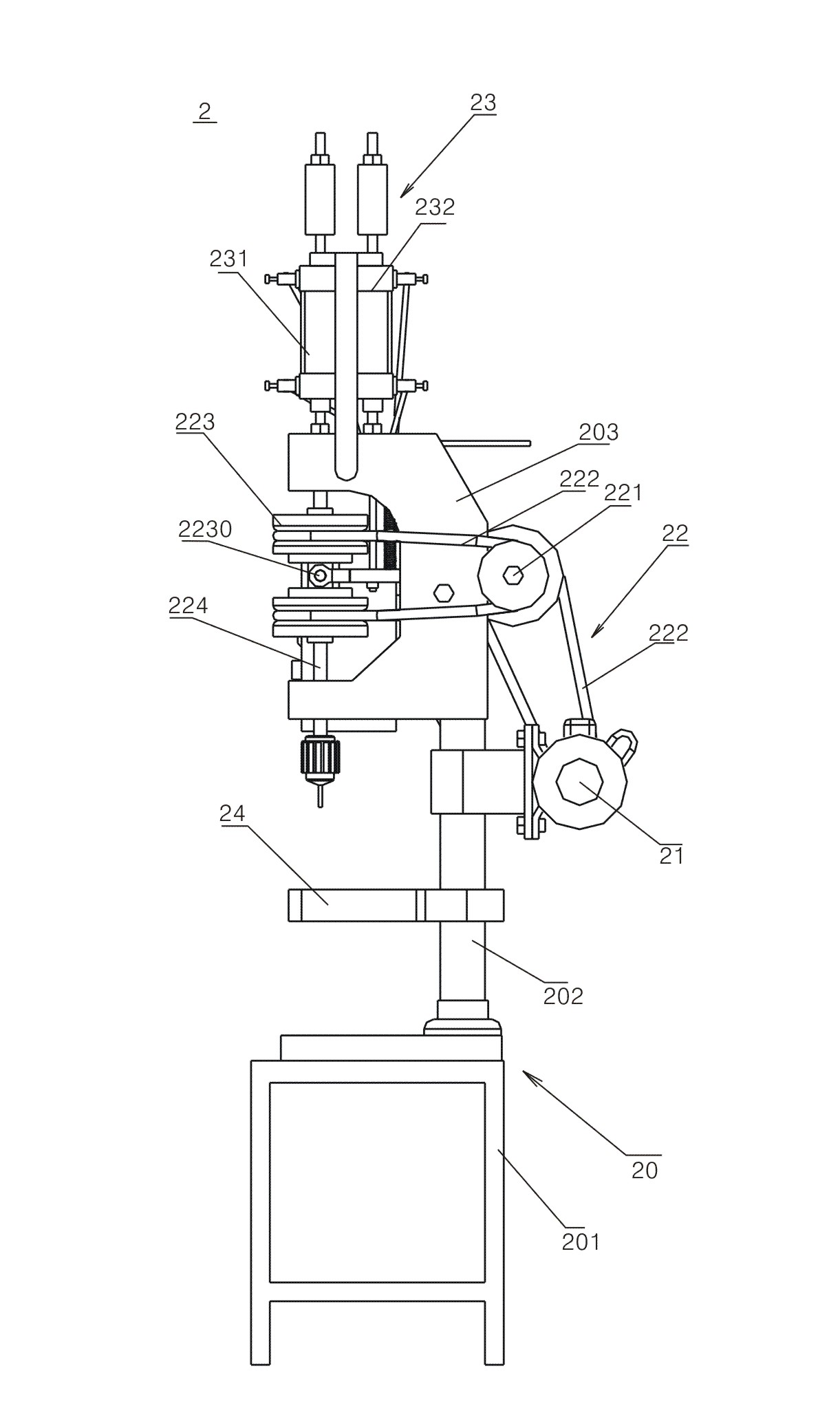

[0026] see in conjunction figure 1 , figure 2 As shown, the embodiment of the present invention provides a soft strip inner hole threading device, which is used to automatically guide and thread the soft strip accessories that are difficult to fix on the machine tool, including conveyor belt accessories and Conveyor and recovery unit 1 for discharging materials after starting operation, starting and receiving unit 2 for automatic starting control of belt accessories, and used for introducing belt accessories, and the position can be adjusted according to the hole distance of belt accessories Adjusted import control section component 3;

[0027] The delivery and recovery assembly 1 includes a delivery disc 11 and a recovery disc 12, the delivery disc 11 is connected to the introduction control section assembly 3, and the recovery disc 12 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com