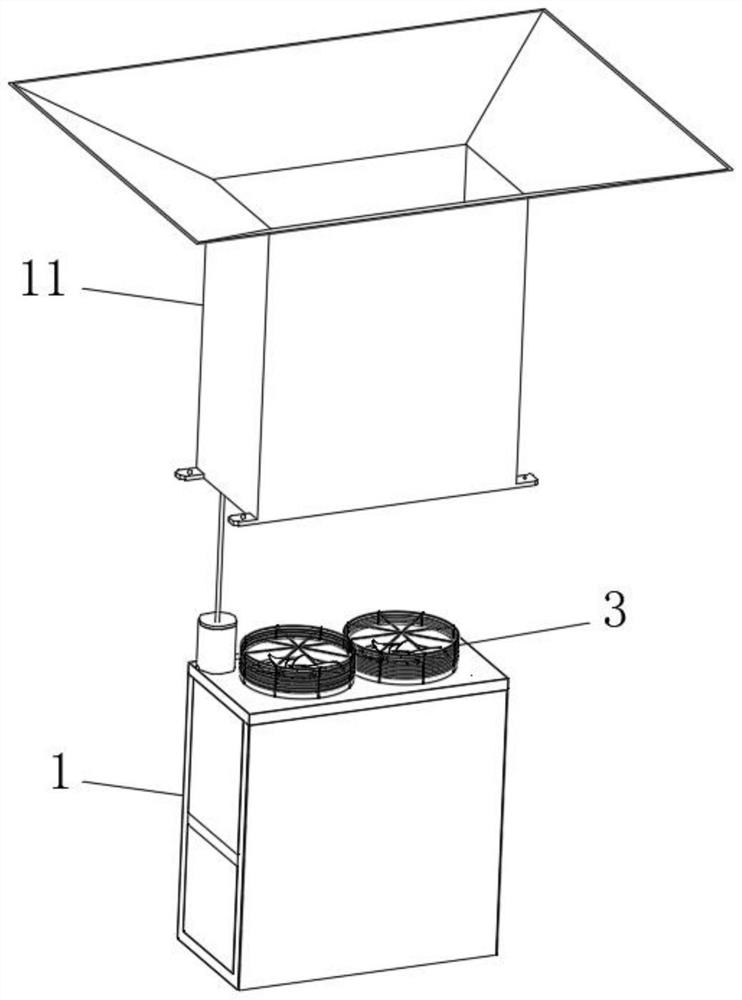

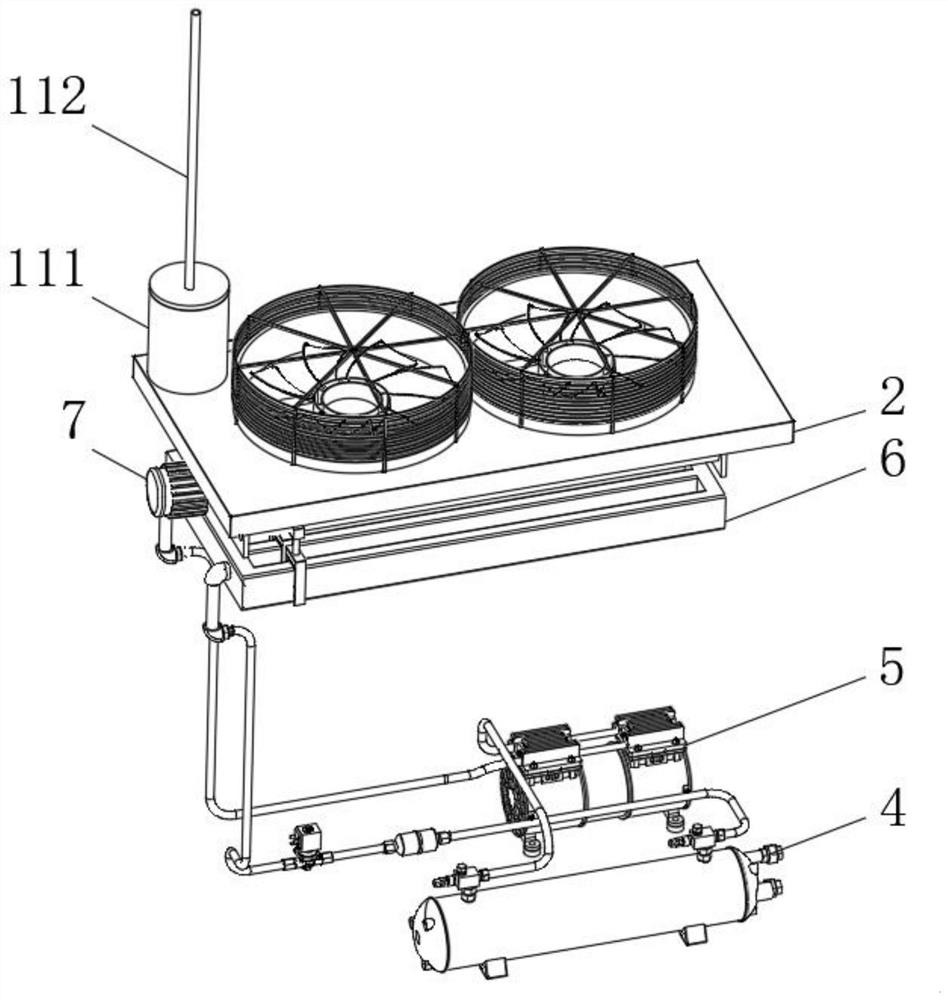

Industrial water chilling unit

A chiller and chiller technology, applied in refrigerators, refrigeration components, general water supply conservation, etc., can solve the problems of wasting resources, high energy consumption of chillers, and a lot of dust, so as to improve heat dissipation efficiency, good heat dissipation effect, and expand collection area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

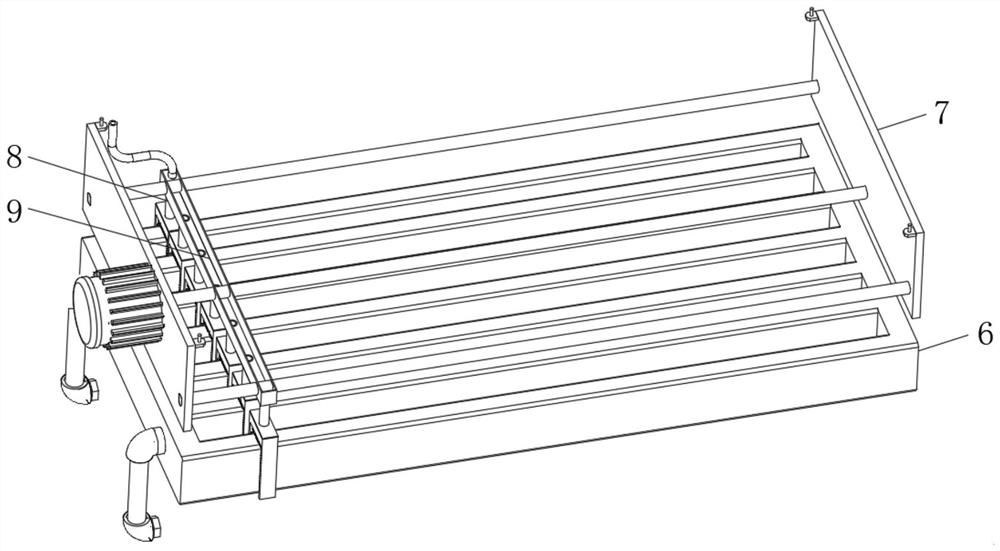

[0046]As an embodiment of the present invention, the cleaning servo motor 71 is fixedly installed on the outer surface of one end of the first fixing plate 72. The first fixing plate 72 and the second fixing plate 73 are both connected to the lower casing 1 of the unit through the disassembly mechanism 10 The outer surface of the lower end can be detachably connected. The two sets of limit rods 75 are fixedly connected to the first fixing plate 72 and the second fixing plate 73. One end of the screw rod 74 extends to the inside of the cleaning servo motor 71, and one end of the screw rod 74 It is fixedly connected with the inner rotor of the cleaning servo motor 71, and the screw 74 is threadedly connected with the internal thread of the moving rod 76, and the moving rod 76 can be kept stably moved outside the screw 74 by the limiting action of the limit rod 75; When working, when the dust brushing mechanism 8 cannot perform automatic dust brushing, the screw 74 is driven to rotate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com