Air exchanger

A technology of air exchanger and exhaust cavity, which is applied in the direction of machines/engines, space heating and ventilation, heating methods, etc. It can solve the problem of not meeting the requirements of large and rapid exchange of indoor and outdoor air, reducing the exhaust efficiency of fan blades, low wind pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

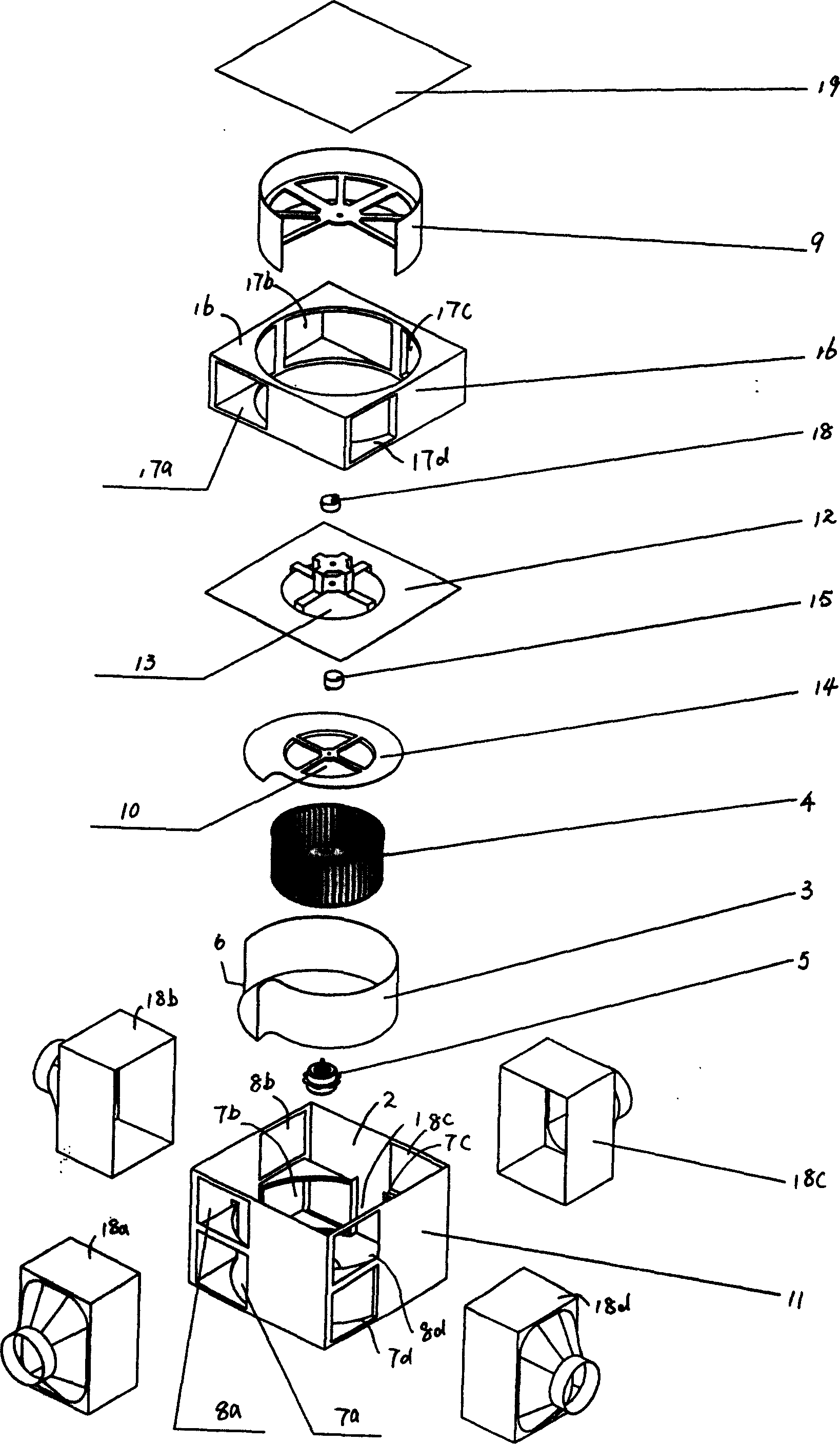

[0017] Refer to attached figure 1 with 2 . The present invention comprises an exhaust cavity 1 and an air suction cavity 2. A volute 3, a centrifugal wind wheel 4 and a motor 5 are arranged in the exhaust cavity. The rotation path of the shell is provided with an exhaust port 7a leading to the outdoor and one or more exhaust ports leading to the room in cooperation with the volute exhaust port 6; The air suction port 8a leading to the outdoor and the air suction port leading to the room are paired with each other. The air suction chamber is provided with a damper 9 for switching the air suction port.

[0018] As an air duct, the volute can provide higher wind pressure, and the volute can also be replaced by other shaped casings, such as circular casings.

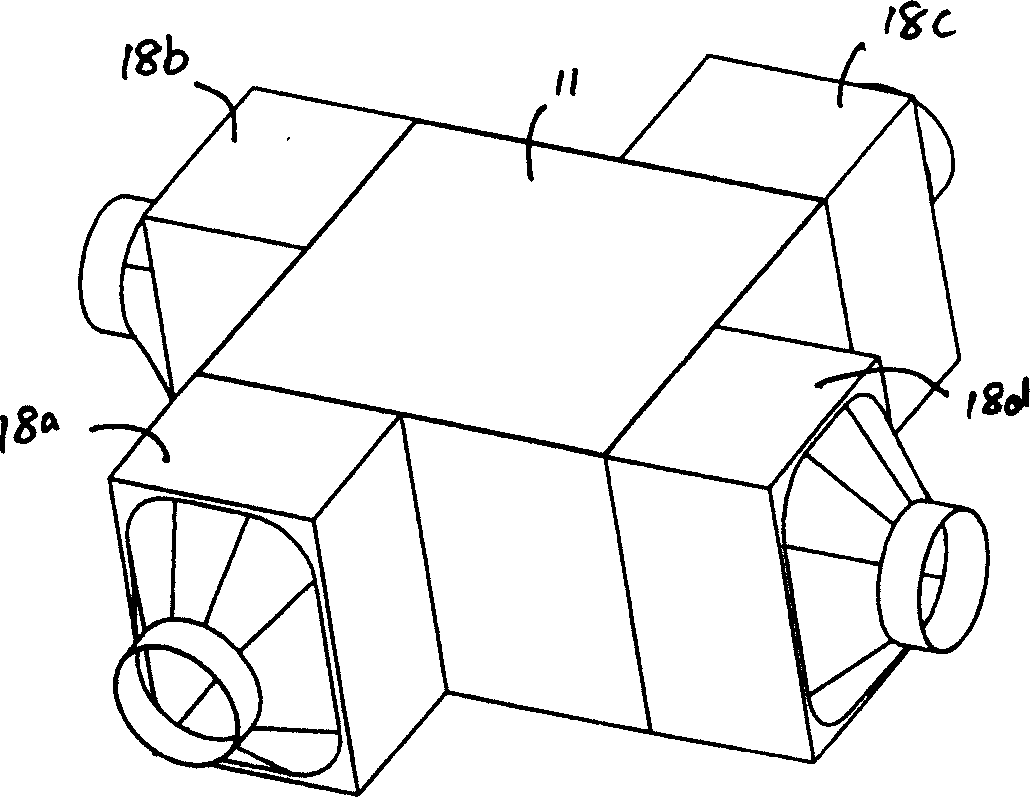

[0019] The present invention is provided with box body 11, and is divided into above-mentioned suction cavity and exhaust cavity by dividing plate 12, dividing plate is provided with air inlet 13, and volute air inlet 10 ...

Embodiment 2

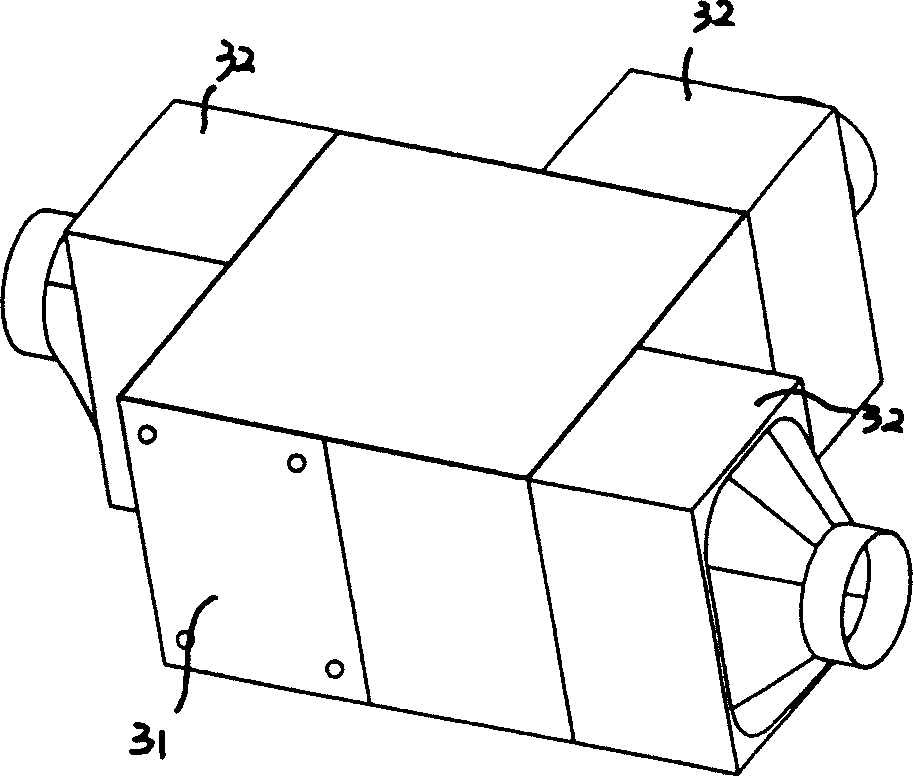

[0026] Refer to attached image 3 , 4 . This embodiment is an outdoor installation type for two bedrooms, so the air-collecting pipe piece may not be connected to the air inlet leading to the outside and the exhaust port of the exhaust cavity.

[0027] Such as image 3 As shown, the rotatable damper is two circular arcs. In this way, when the damper is in the state that the air inlet leading to the outside is opened, the air inlet leading to the room is closed. By rotating the volute, the outlet is aligned with a certain air inlet. The exhaust port of the room can inhale fresh outdoor air for the room. When the state of the damper is that the suction port leading to the outside is closed, the damper opens the suction port of all rooms. By rotating the volute, it is aligned with the The outdoor exhaust port can discharge indoor dirty air to all rooms.

[0028] Others are the same as embodiment 1. The same parts in the two embodiments have the same reference numerals in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com