Blast deflector of fan

A fan diversion and fan technology, which is applied to components, instruments, and electrical digital data processing of pumping devices for elastic fluids, and can solve problems such as reduced heat exchange efficiency, affecting heat dissipation, airflow velocity, and pressure reduction. , to achieve the effect of increasing wind pressure and wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the embodiments with reference to the accompanying drawings.

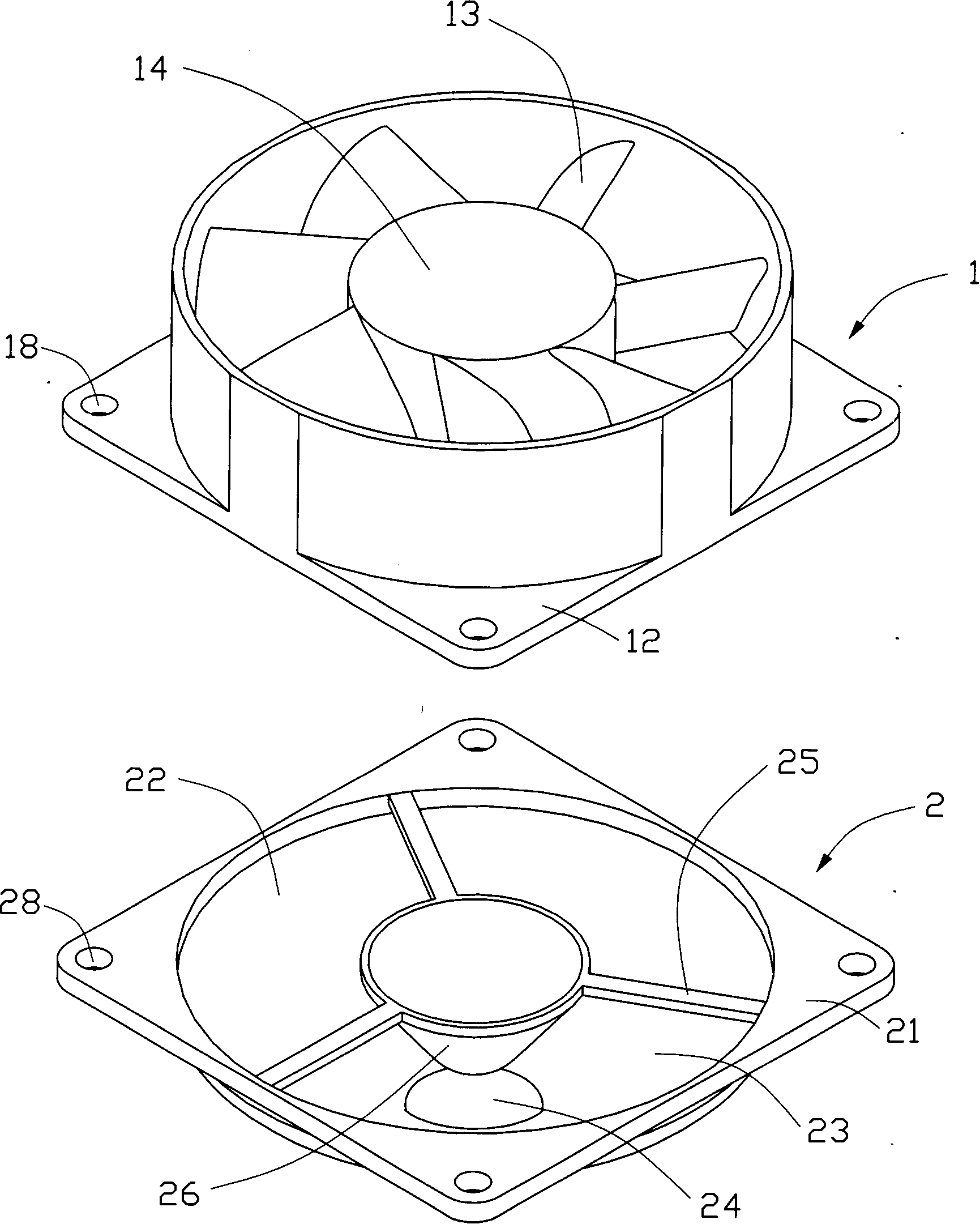

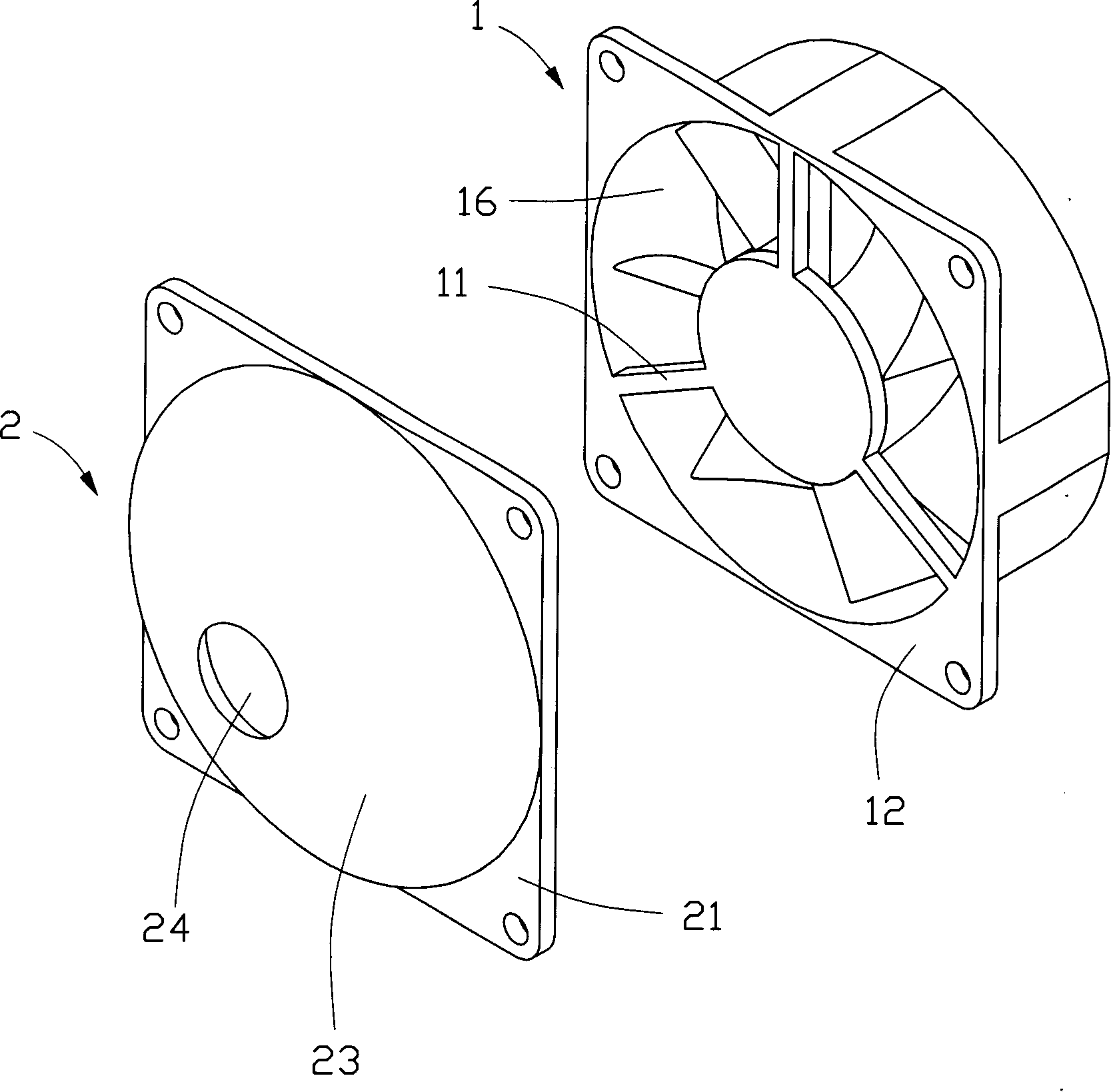

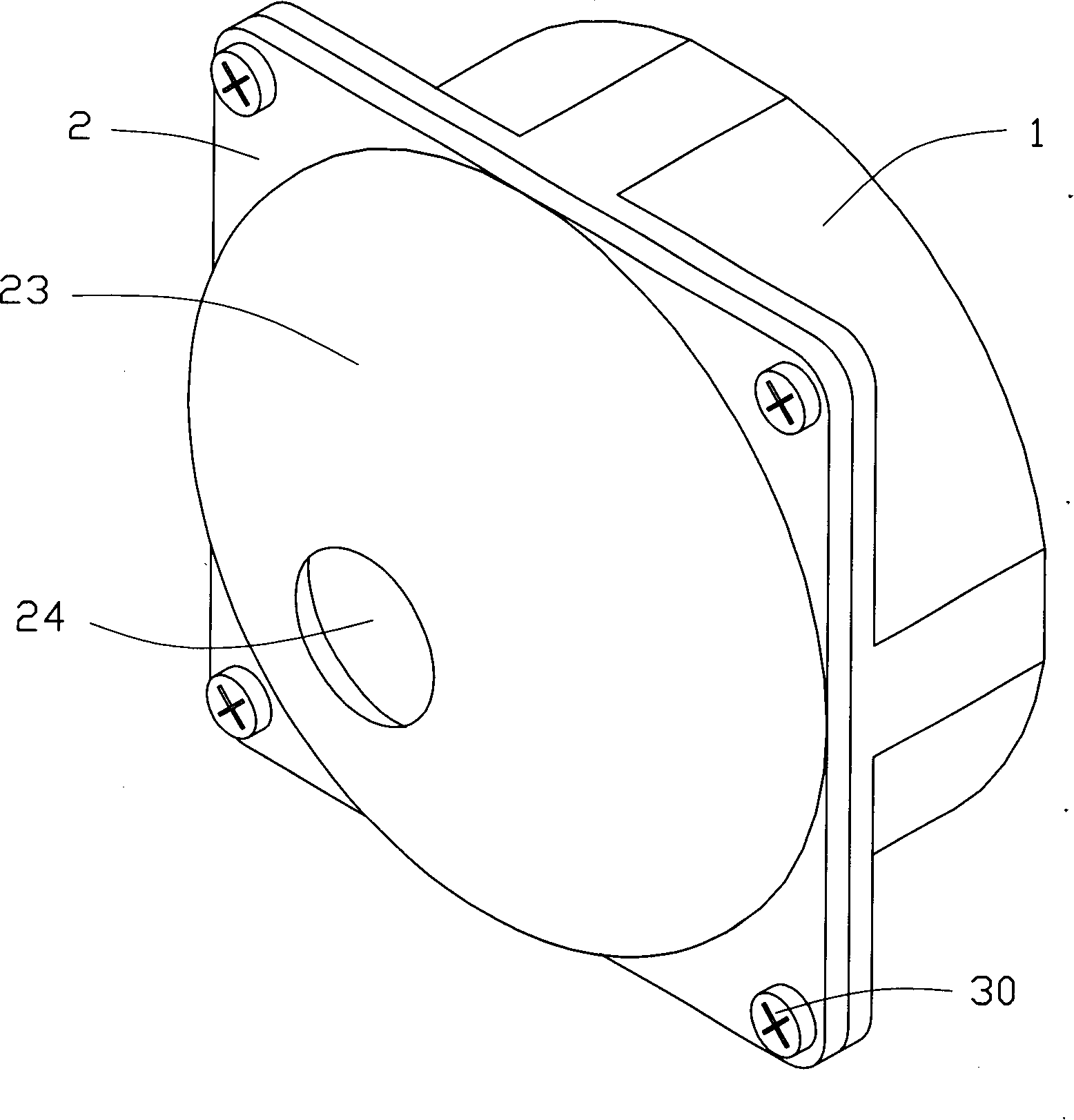

[0014] Such as figure 1 and figure 2 As shown, the fan guide device 2 of the present invention is installed on the air outlet side of the fan 1 .

[0015] The fan 1 includes a fan frame 12, a hub 14 disposed in the fan frame 12, a support frame 11 placed below the hub 14 to support the hub 14, and a plurality of fan blades 13 extending radially outward from the periphery of the hub 14, The support frame 11 is located on the air outlet side 16 of the fan 1 , and the four corners of the fan frame 12 on the air outlet side 16 of the fan 1 are also provided with through holes 18 for fixing parts such as screws 30 to pass through.

[0016] The fan deflector 2 includes a deflector 23 and a guide body 26 inside the deflector 23 . The shroud 23 is roughly in the shape of a nozzle, with a circular cross-section, and a streamlined curved su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com