Combination axial-flow fan

a technology of axial flow and fan, which is applied in the field of fans, can solve the problems of mold stripping, inapplicability to design, and difficulty in satisfying the heat dissipation requirements of modern electronic devices, and achieves the effects of high wind pressure, low noise level characteristics, and high wind capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

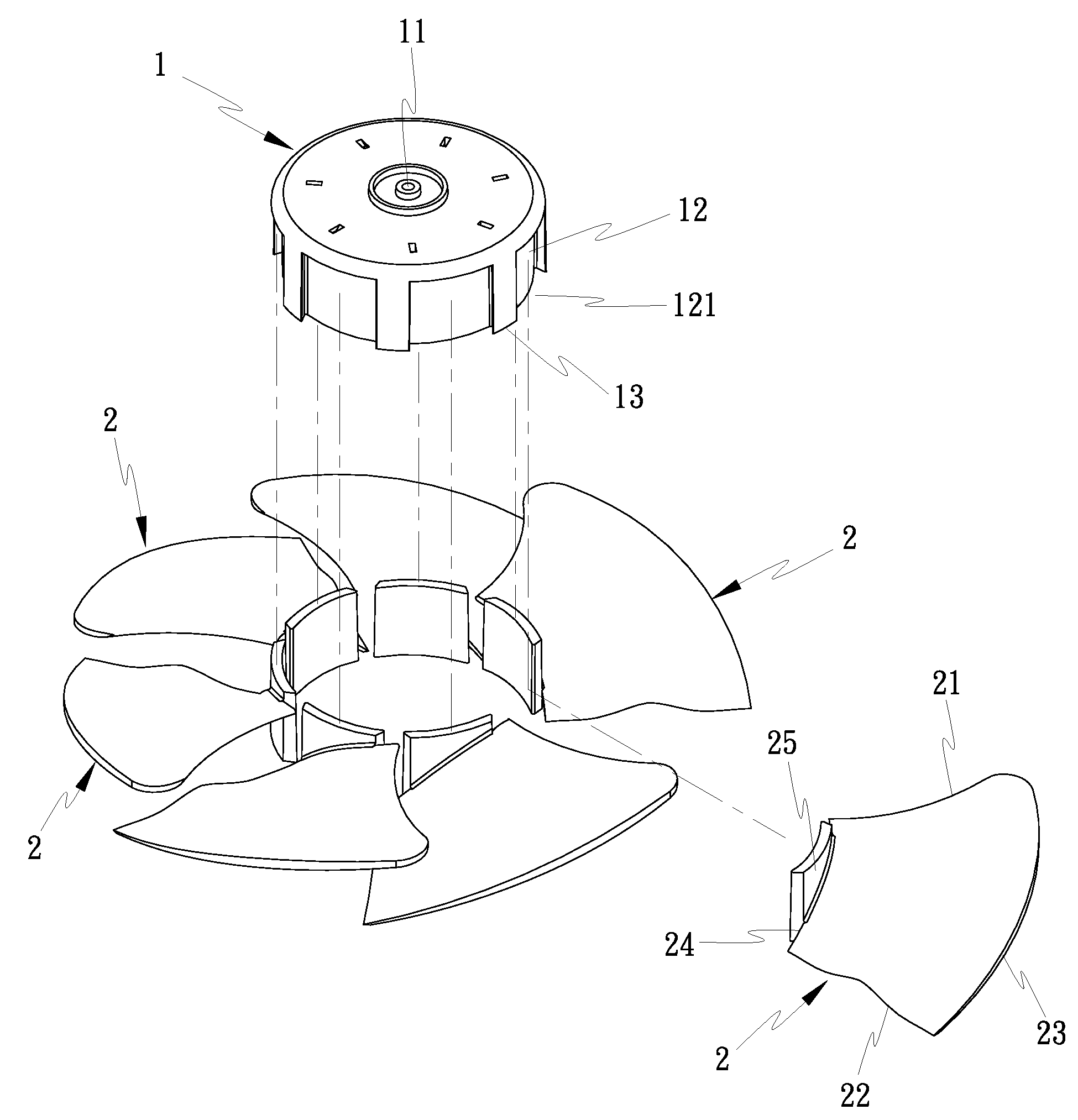

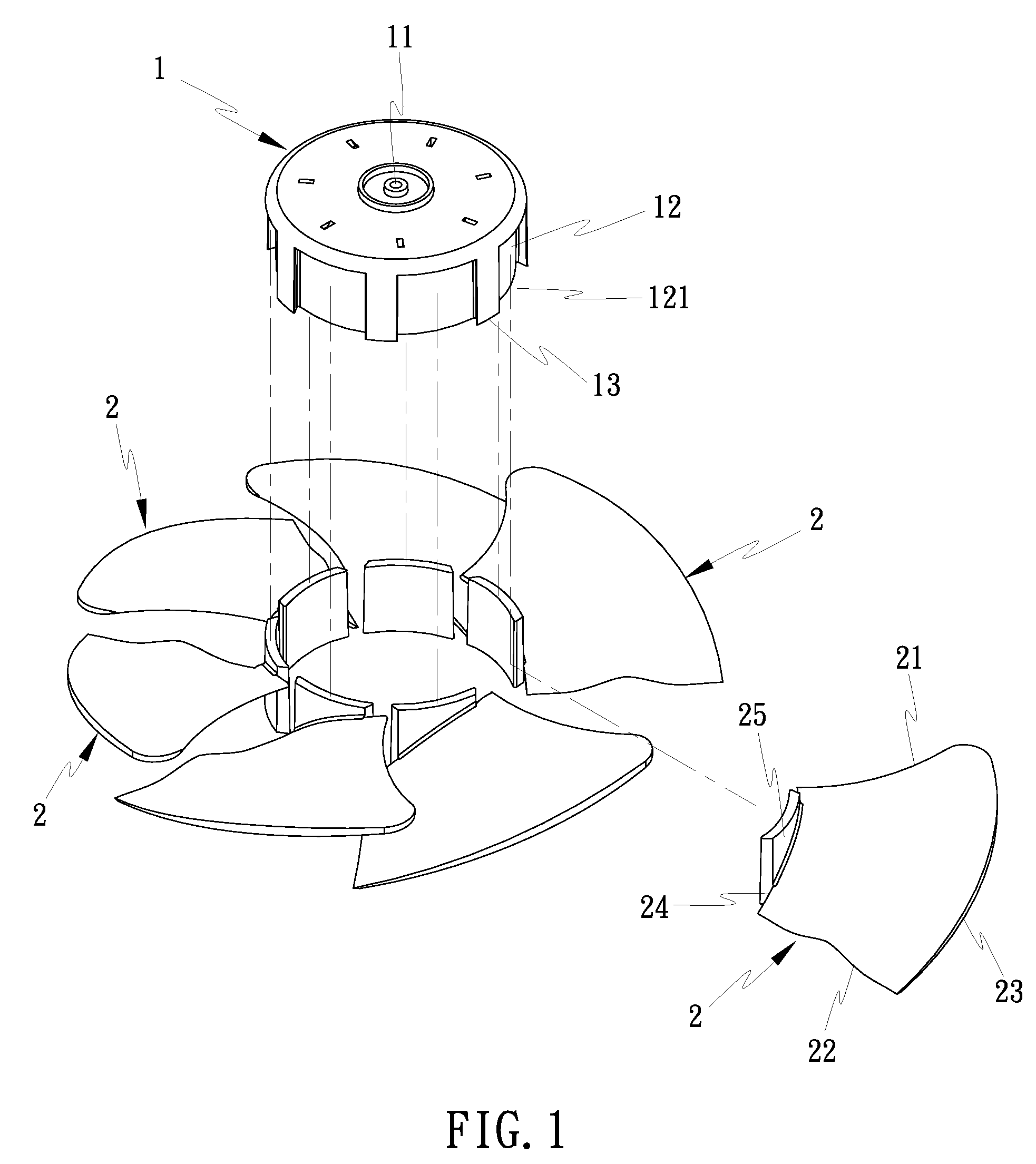

[0014]With reference to FIGS. 1 and 2, a combination axial-flow fan in accordance with the present invention comprises a fan hub 1 and a plurality of fan blades 2. The fan hub 1 and the fan blades 2 are separately molded from plastics by means of injection molding, and then assembled together for use as an active heat dissipation device for the cooling of an electronic product.

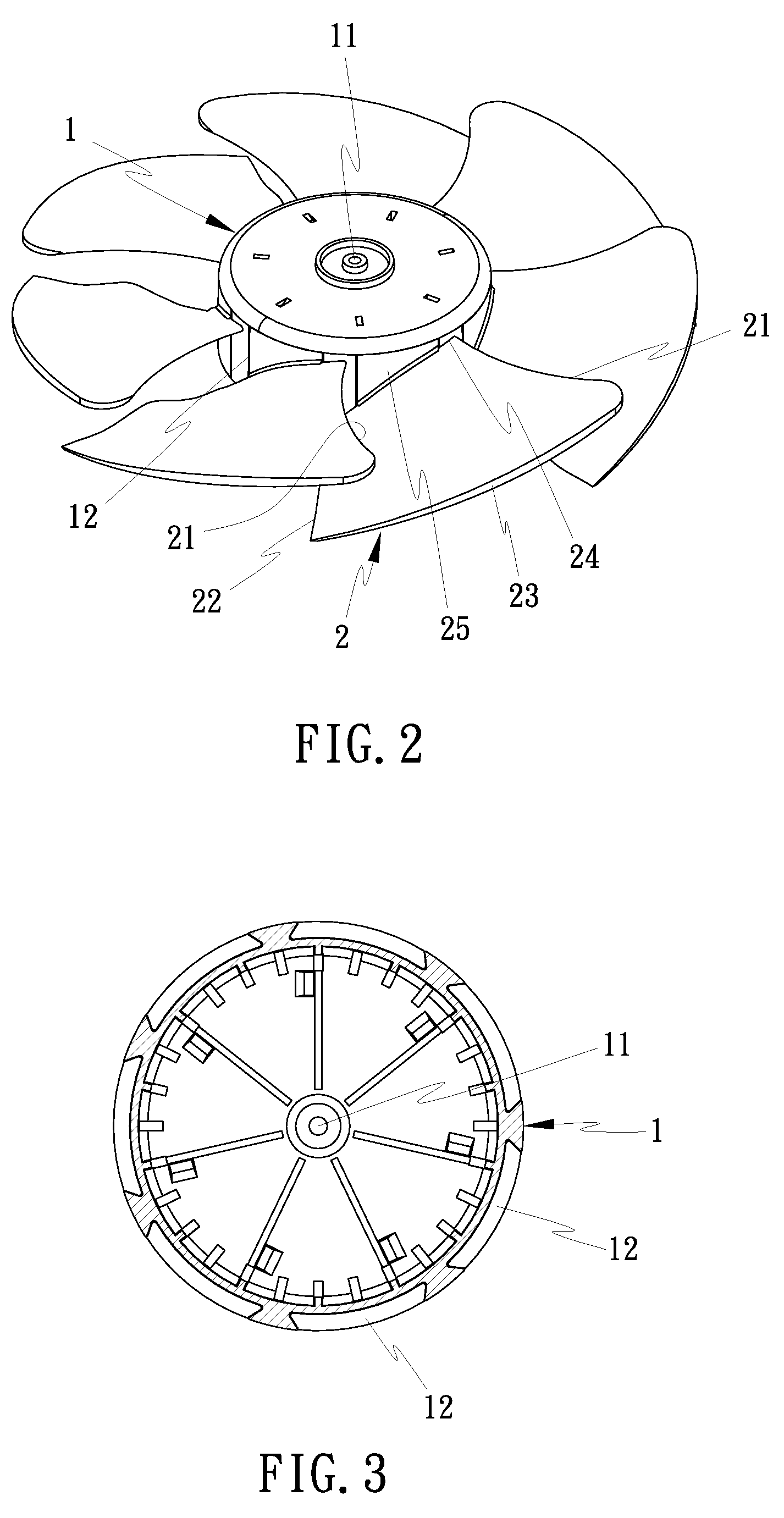

[0015]Referring to FIGS. 1 and 2 again, the fan hub 1 may be made in any of a variety of shapes. According to the present preferred embodiment, the fan hub 1 is shaped like a round cap, having a center connection portion 11 at the center for the connection of the shaft of a fan motor (not shown), and a plurality of mounting grooves 12 equiangularly spaced around the periphery. The mounting grooves 12 can be dovetail grooves extending axially towards the rear side 13 of the fan hub 1 so that each mounting groove 12 has an open end 121 at the rear side 13 of the fan hub 1.

[0016]Referring to FIGS. 1 and 2 again, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com