Double-layer reverse axial fan

An axial-flow fan and reversing shaft technology, which is applied in the field of double-layer reversing axial-flow fans, can solve the problems of low fan efficiency and low heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

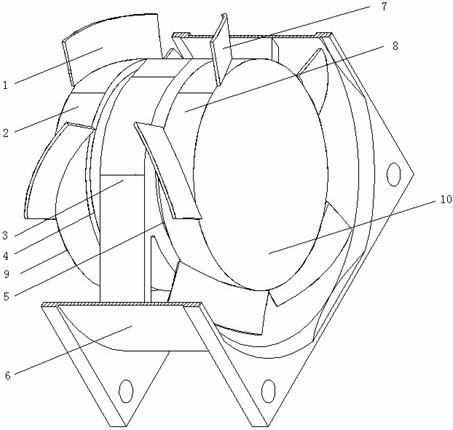

[0011] Such as figure 1 As shown, the double-layer counter-rotating axial flow fan includes a plurality of first blades 1, a first axial flow fan 2, a motor fixing frame 3, a first motor 4, a second motor 5, a casing 6, and a plurality of second blades 7 , the second axial flow fan 8, the first hub 9 and the second hub 10; on the casing 6, a motor fixing frame 3 is fixed, on the motor fixing bracket 3, the first motor 4 and the second motor 5 are fixed, and on the first motor 4 is fixed with a first axial fan 2 on the rotating shaft, the first axial fan 2 includes a first hub 9 and a first blade 1, the first hub 9 is fixed with a first blade 1, and the rotation of the second motor 5 A second axial fan 8 is fixed on the shaft. The second axial fan 8 includes a second hub 10 and a second blade 7. The second hub 10 is fixed with a second blade 7. The first axial fan 2 and The rotation speed of the second axial flow fan 8 is the same, but the rotation direction is opposite, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com