Integrated residual pressure recovery device

A recovery device and residual pressure technology, applied in the direction of pump devices, noise reduction devices, exhaust devices, etc., can solve problems such as large market application space, and achieve the effect of improving energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

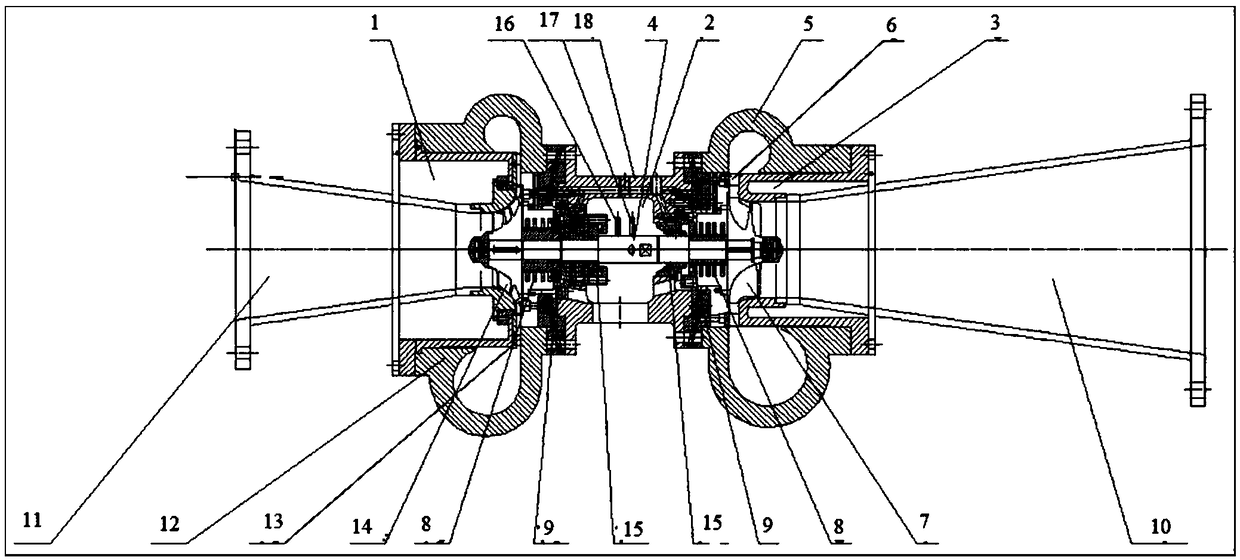

Embodiment 1

[0037]The integrated residual pressure recovery device in the present invention mainly uses a turbine to recover the residual pressure of nitric acid tail gas, directly drives the nitrogen oxide compressor, and adopts a high-speed machine to make the device body small and light, and the integrated machine can simplify the system and structure . Nitrogen oxide and other mixed gases are poisonous and corrosive, so they cannot leak. This integrated residual pressure recovery device uses carbon rings to seal 8 process gases, and adds a third gas for isolation. In addition, it is necessary to prevent the process gas from entering the oil system, otherwise it will pollute the oil quality; use honeycomb seals to seal 9 oils, because the lubricating oil in the nitric acid industry cannot enter the nitrogen oxide gas, otherwise it will cause an explosion; the strict sealing system is an integrated residual pressure One of the key technical problems to be solved by the recovery device. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com