A water outlet channel with flow self-balancing function

A self-balancing, water flow channel technology, applied in the direction of pipe components, mechanical equipment, pipes/pipe joints/fittings, etc., can solve problems such as uneven flow distribution, increased energy consumption of pumping stations, and obvious differences in the average speed of outflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

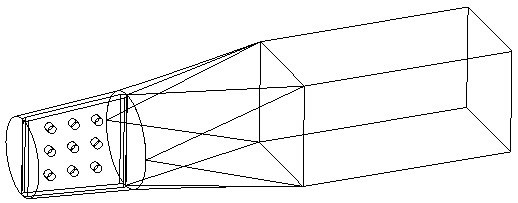

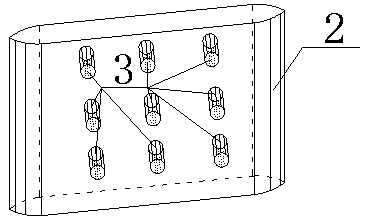

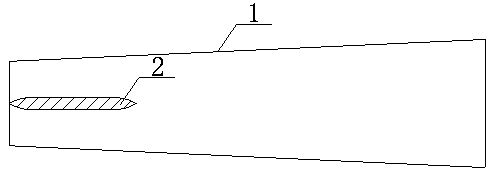

[0019] The present invention will be further described below with reference to the accompanying drawings and the description of the drawings.

[0020] Taking a small and medium-sized pumping station as an example to illustrate, a water outlet channel 1 with flow self-balancing function is made by cast-in-place reinforced concrete vertical formwork, and the middle pier 2 is also cast in the same way when the water outlet channel vertical formwork is poured. Casting production, the artesian hole 3 is pre-buried in the middle pier 2 with PVC pipe or metal pipe, the length of the artesian hole is equal to the thickness of the middle pier, and the number of the artesian hole is set according to the length and height of the middle pier 2, Generally, it should be controlled between 9 and 12, and the top and bottom of the middle pier are consolidated with the inner wall of the outlet channel to ensure the overall stability of the outlet channel 1 and the middle pier 2.

[0021] When i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com