Centrfugal fan for oil and smoke exhaust machine and method for manufacturing volute profile line thereof

A technology of centrifugal fans and range hoods, which is applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., and can solve the deterioration of the unevenness of the airflow at the outlet of the impeller, the decrease of the air volume, air pressure and efficiency of the fan, and the uneven airflow at the outlet of the impeller and other problems, to achieve the effect of simple and reasonable volute structure, low efficiency and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

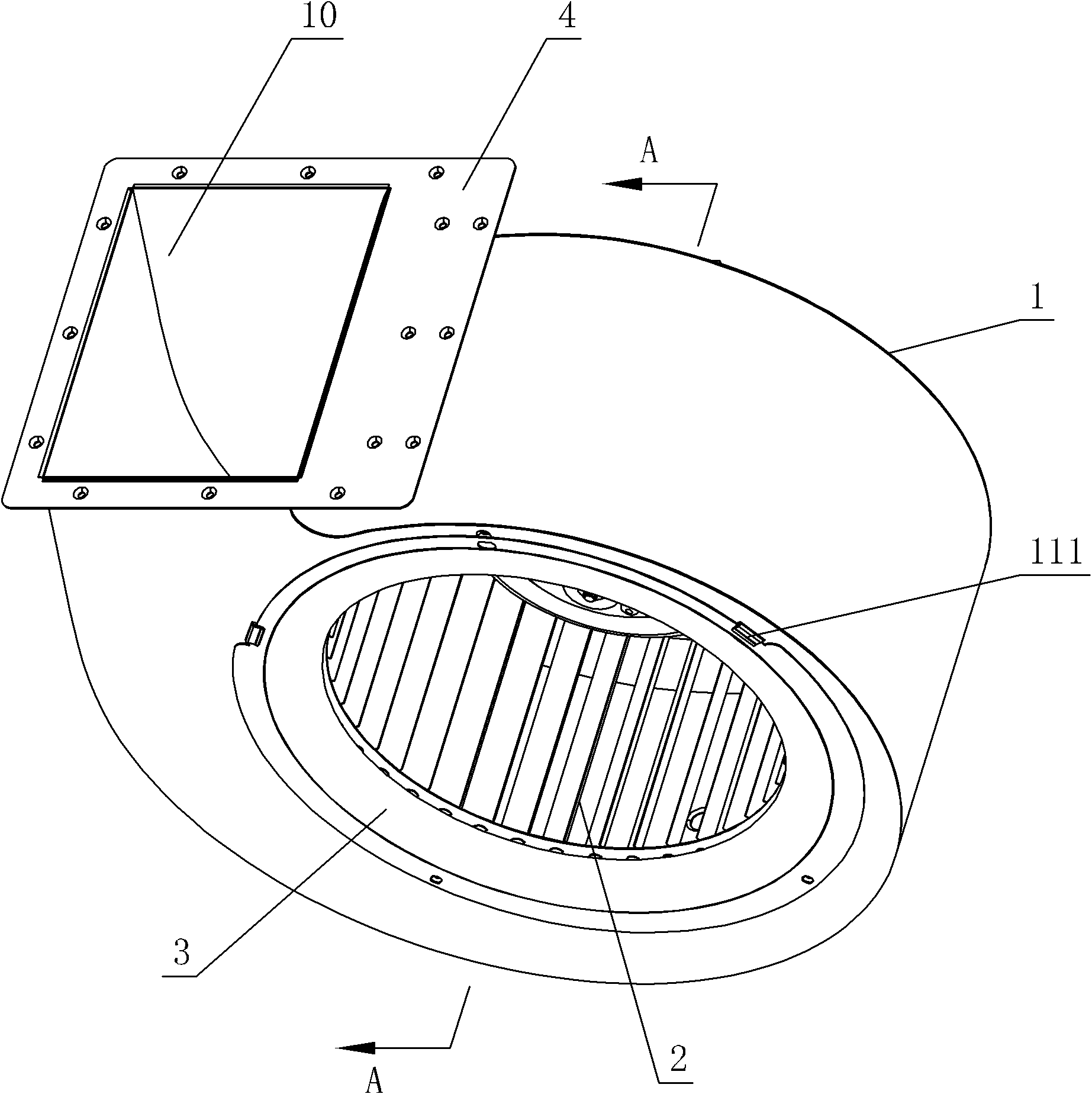

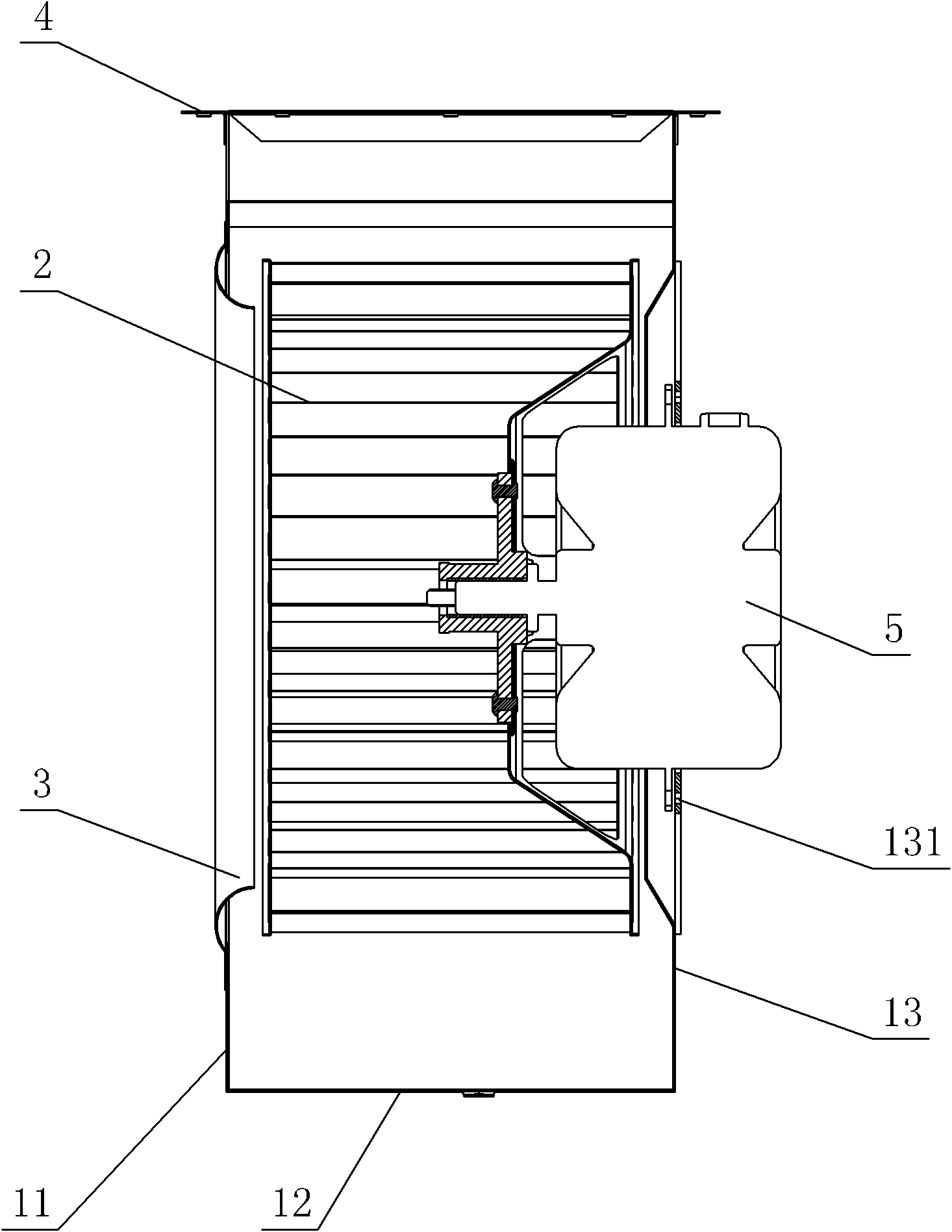

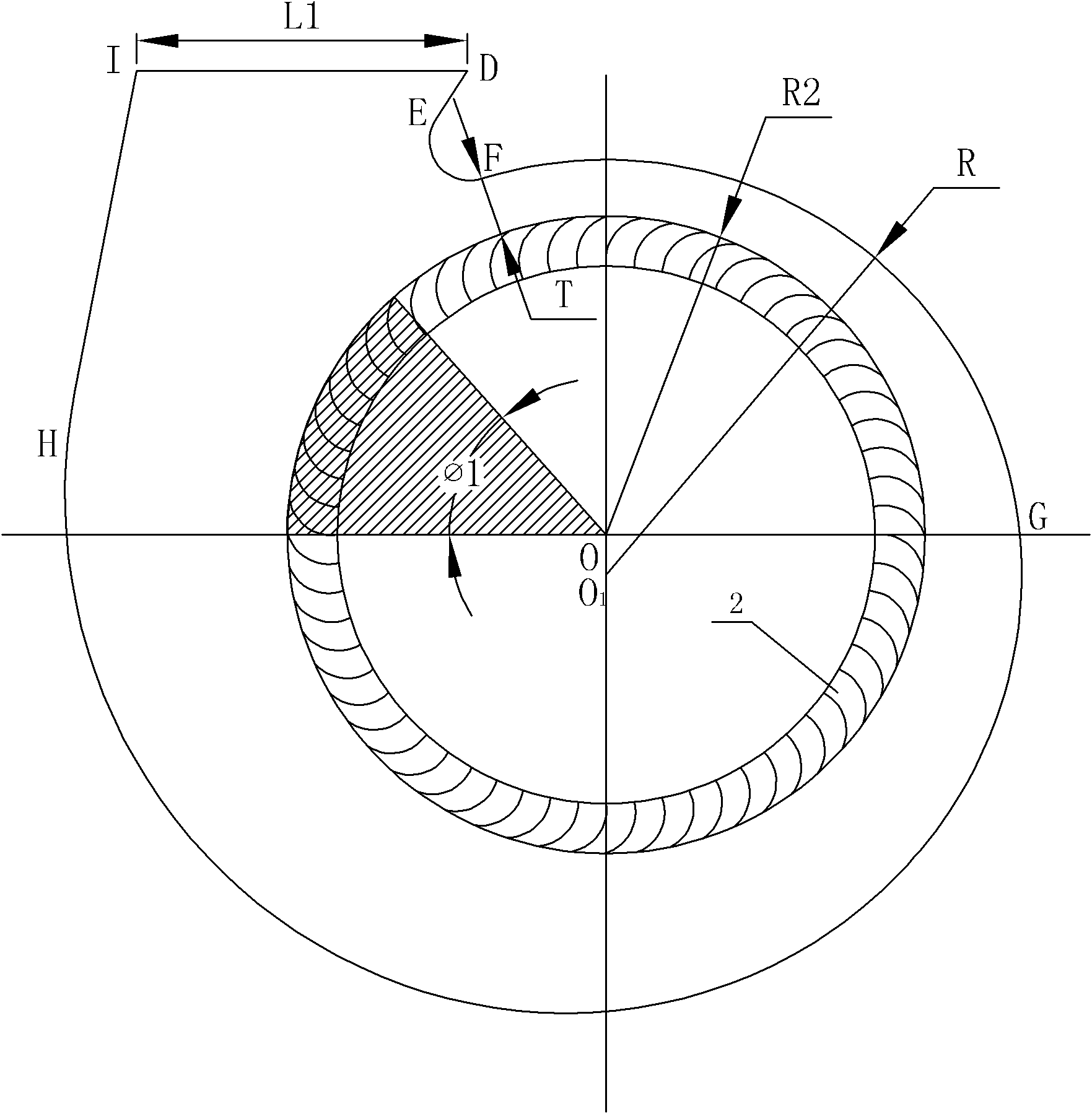

[0027] see Figure 1-Figure 2 , the centrifugal fan for the range hood, including a volute 1 provided with an air inlet and an air outlet 10, an impeller 2 arranged in the volute 1, an air inlet ring 3 arranged on the air inlet, and a motor for driving the impeller 2 to rotate 5. The volute 1 includes a volute top plate 11 , a volute coaming 12 and a volute bottom 13 , and the volute coaming 12 is connected between the volute top 11 and the volute bottom 13 . The volute coaming plate 12 is formed by smooth transition connection of the first plane, the first arc surface, the second arc surface, the spiral surface and the second plane. The helicoid is a constant velocity helicoid. The upper and lower ends of the volute coaming 12 are respectively connected to the outer edges of the volute top plate 11 and the volute bottom plate 13 by welding; the air o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com