Range hood

A technology for range hoods and fan racks, which is applied in the direction of removing oil fumes, mechanical equipment, machines/engines, etc. It can solve the problems of not eliminating associated eddy currents, lack of diversion surfaces, increased noise, etc., and reduce local backflow and eddy kinetic energy Loss, avoid eddy current, reduce noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

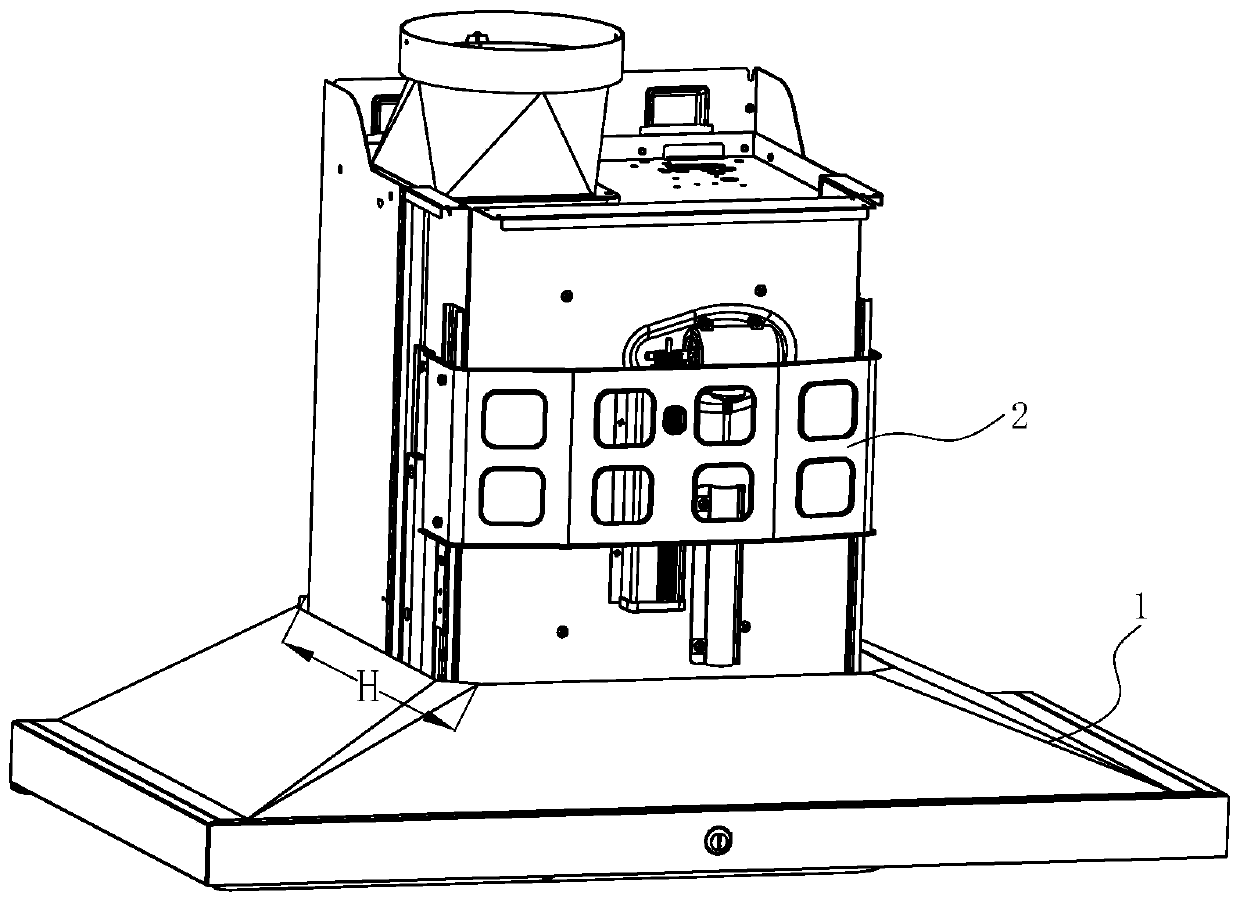

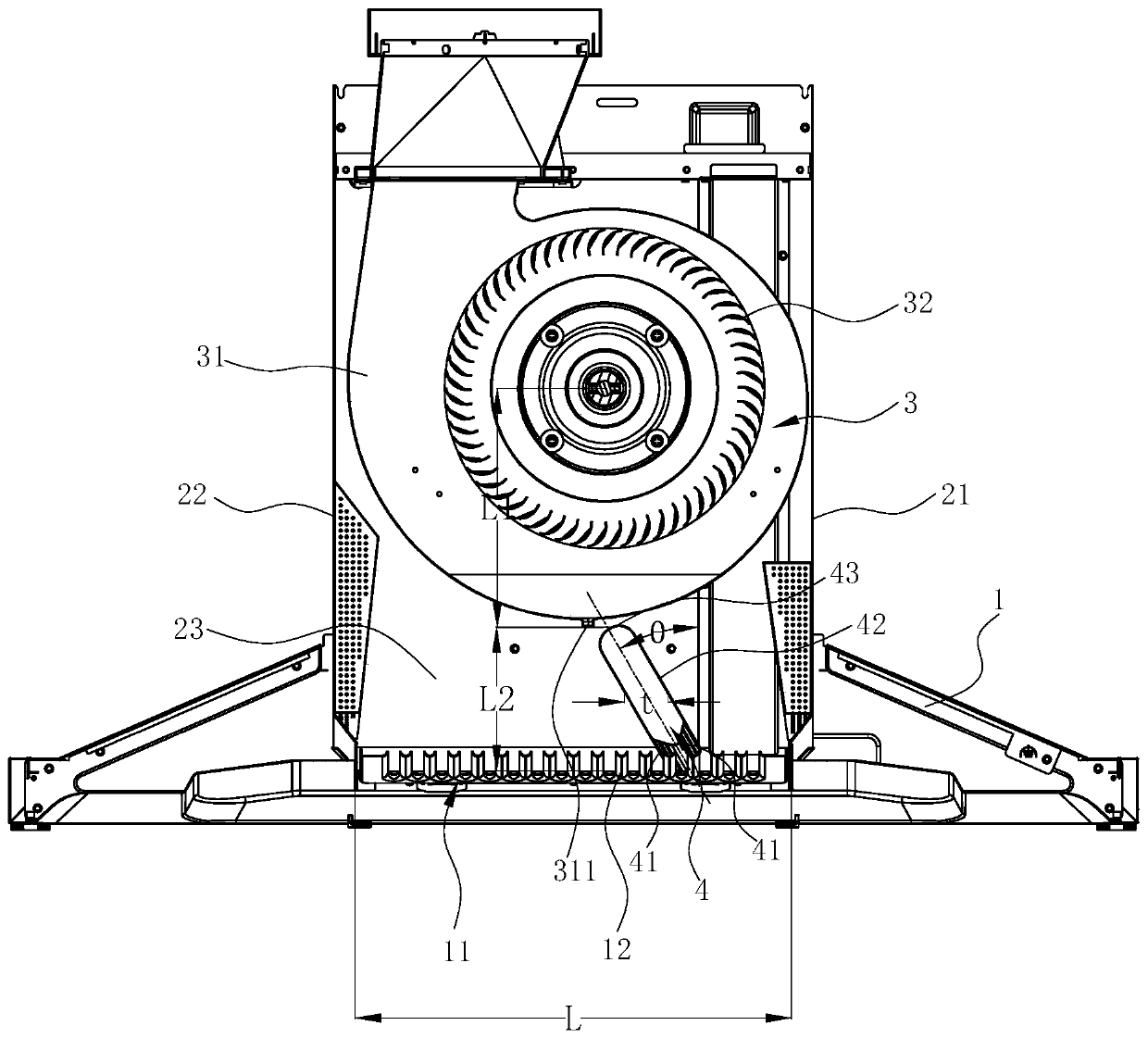

[0033] see Figure 1 ~ Figure 3 , a range hood, including a smoke collection hood 1, a fan frame 2 arranged above the smoke collection hood 1, and a fan system 3 arranged in the fan frame 2. The blower system 3 includes a volute 31 and an impeller 32 arranged in the volute 31 .

[0034] A vortex and noise reducer 4 is arranged inside the fan frame 2 , and the vortex and noise reducer 4 is arranged below the fan system 3 . An air inlet 11 is opened on the smoke collecting hood 1 , and the vortex and noise reducer 4 is located above the air inlet 11 .

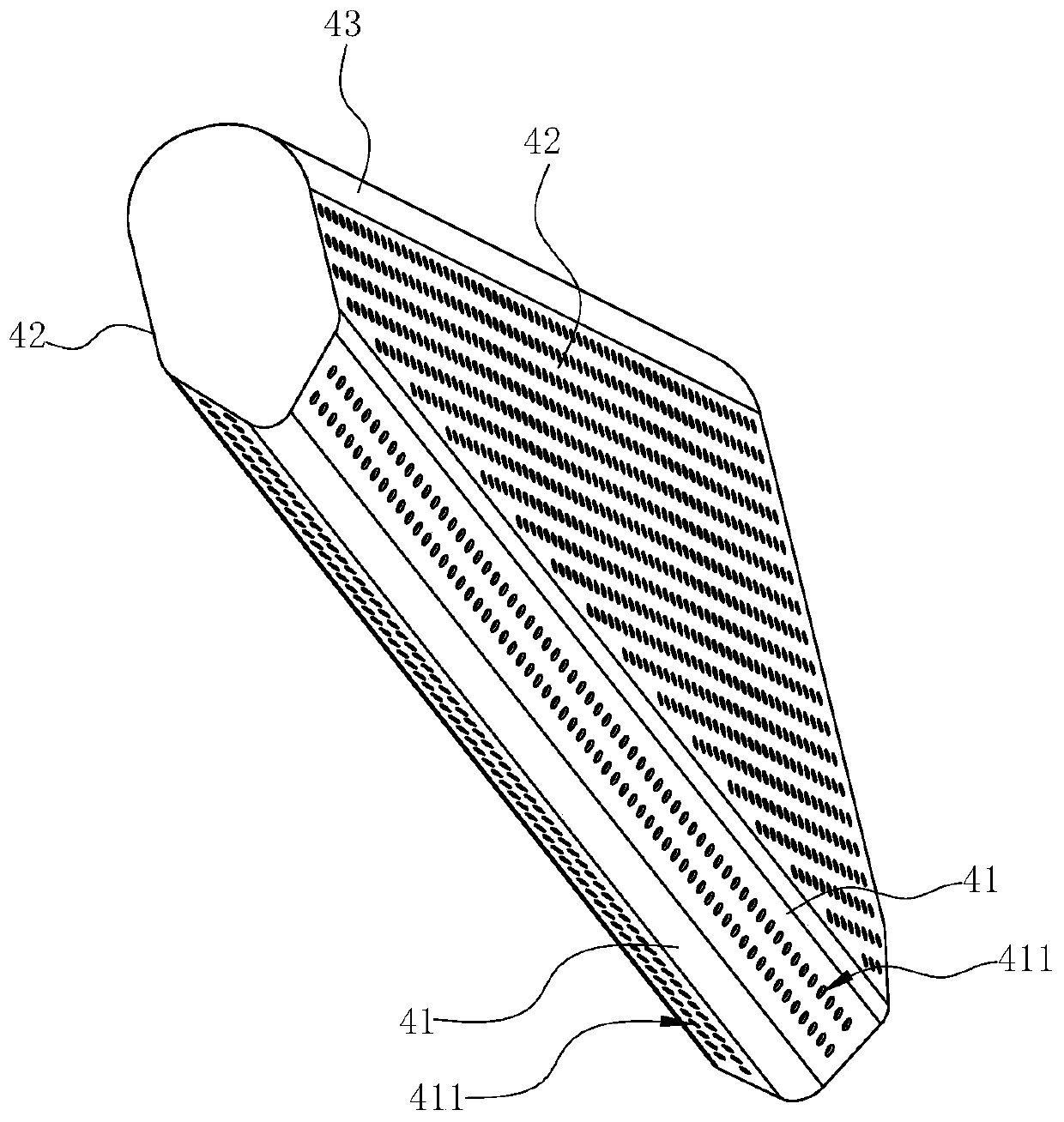

[0035] The vortex and noise reducer 4 is a cylinder with a windward wall 41 at the bottom, a flow guide wall 42 at the side and an airflow separation wall 43 at the top. There are two windward wall surfaces 41 , one ends of the two windward wall surfaces 41 are connected to each other, and the other ends gradually extend upward in directions away from each other. The windward wall surface 41 gradually slopes downward from fron...

Embodiment 2

[0060] see Figure 7 , In this embodiment, the difference from the first embodiment above is that in order to further reduce noise and solve the problem of oil conduction, the vortex and noise reducer 4 is given the function of conducting oil and reducing the noise of the oil leakage nozzle. For this reason, the vortex and noise reducer 4 is made into a hollow structure, and the oil leakage nozzle 311 at the bottom of the volute 31 of the fan system 3 is connected with the vortex and noise reducer 4, and is close to the fan frame below the vortex and noise reducer 4. The position of the rear plate 23 of 2 is open, so that the oil is guided to the rear plate of the fan frame 2 at the opening. At this time, the hollow vortex and noise reducer 4 becomes an oil guide groove at the same time, so that the oil leakage nozzle 311 can be avoided. The oil inside changes the descending route under the impact of the upper and lower airflows, causing oil droplets to drop through the oil ne...

Embodiment 3

[0062] In this embodiment, the difference from the second embodiment above is that the oil leakage nozzle 311 and the vortex and noise reducer 4 are connected through a noise reduction pipe 312, and a noise reduction hole is opened on the noise reduction pipe 312, and the diameter of the noise reduction hole is 5≥φ≥0.5, more preferably φ=1.5, the vortex and noise reducer 4 is in a sealed state, and communicates with the outside world only through the noise reduction hole on the wall of the noise reduction pipe 312, and the noise reduction pipe 312 extends to the fan On the rear plate 23 of the frame 2, the high-speed gas and grease ejected from the oil leakage nozzle 311 enter the noise reduction pipe 312, and the grease is guided to the rear plate 23 of the fan frame 2 along the noise reduction pipe 312, which can avoid leakage. The oil in the oil nozzle 311 changes its descending route under the impact of the upper and lower airflows, causing oil droplets to drip through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com