Double-air-inlet centrifugal fan

A technology of centrifugal fan and double air intake, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc. It can solve the problems of uneven speed distribution of the impeller outlet, so as to overcome the uneven speed distribution, reduce the rotation noise, and increase the air volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

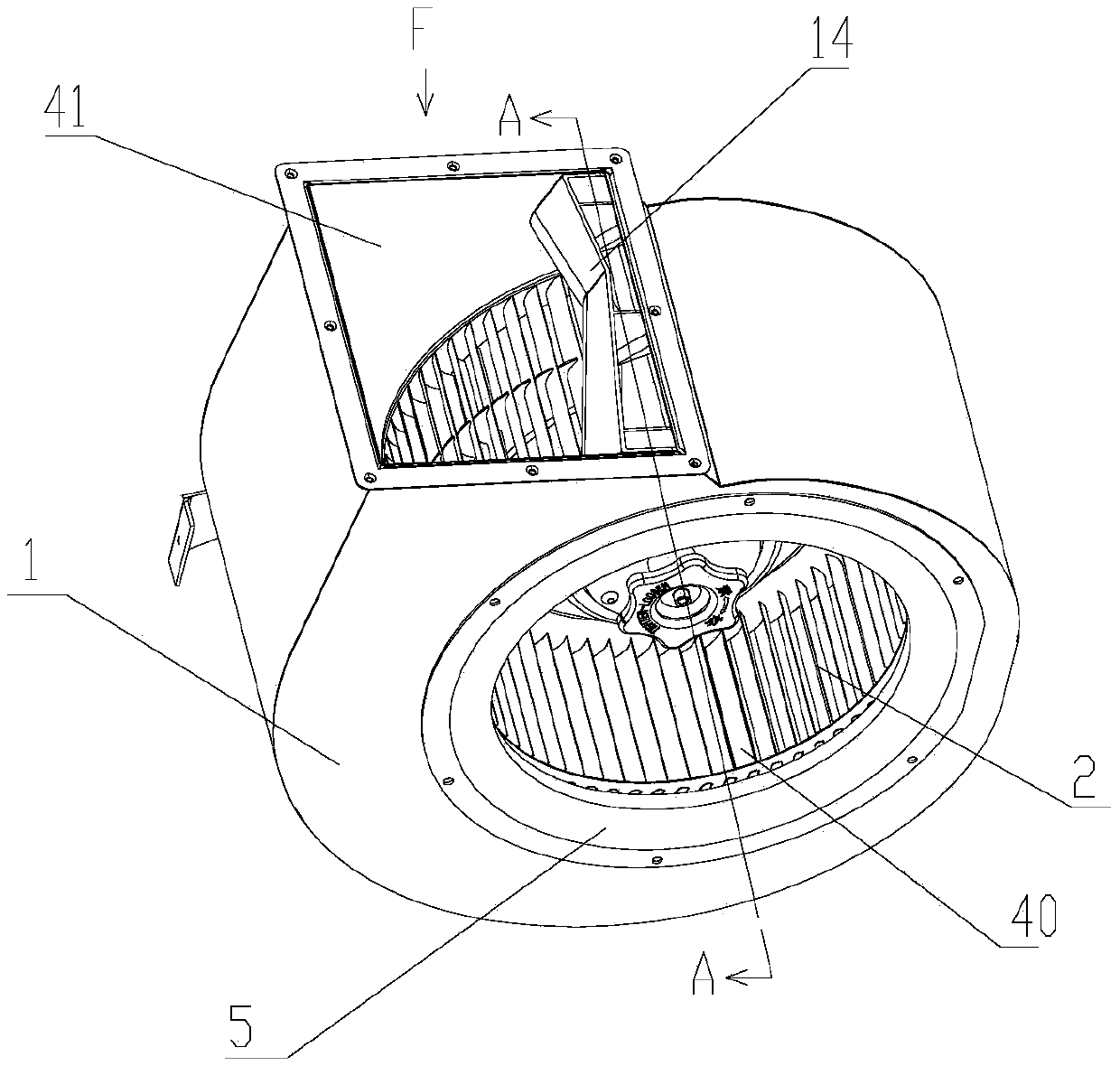

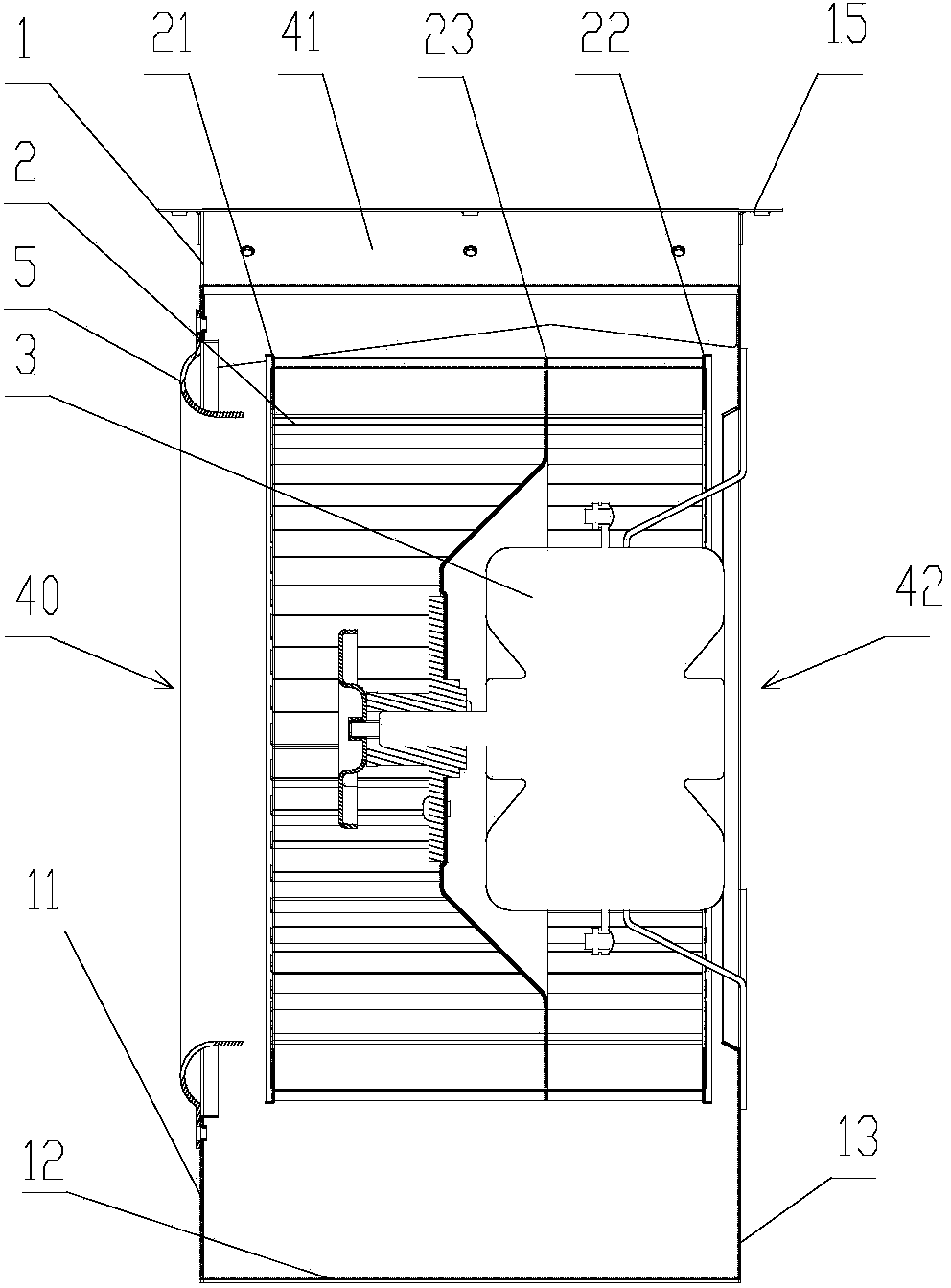

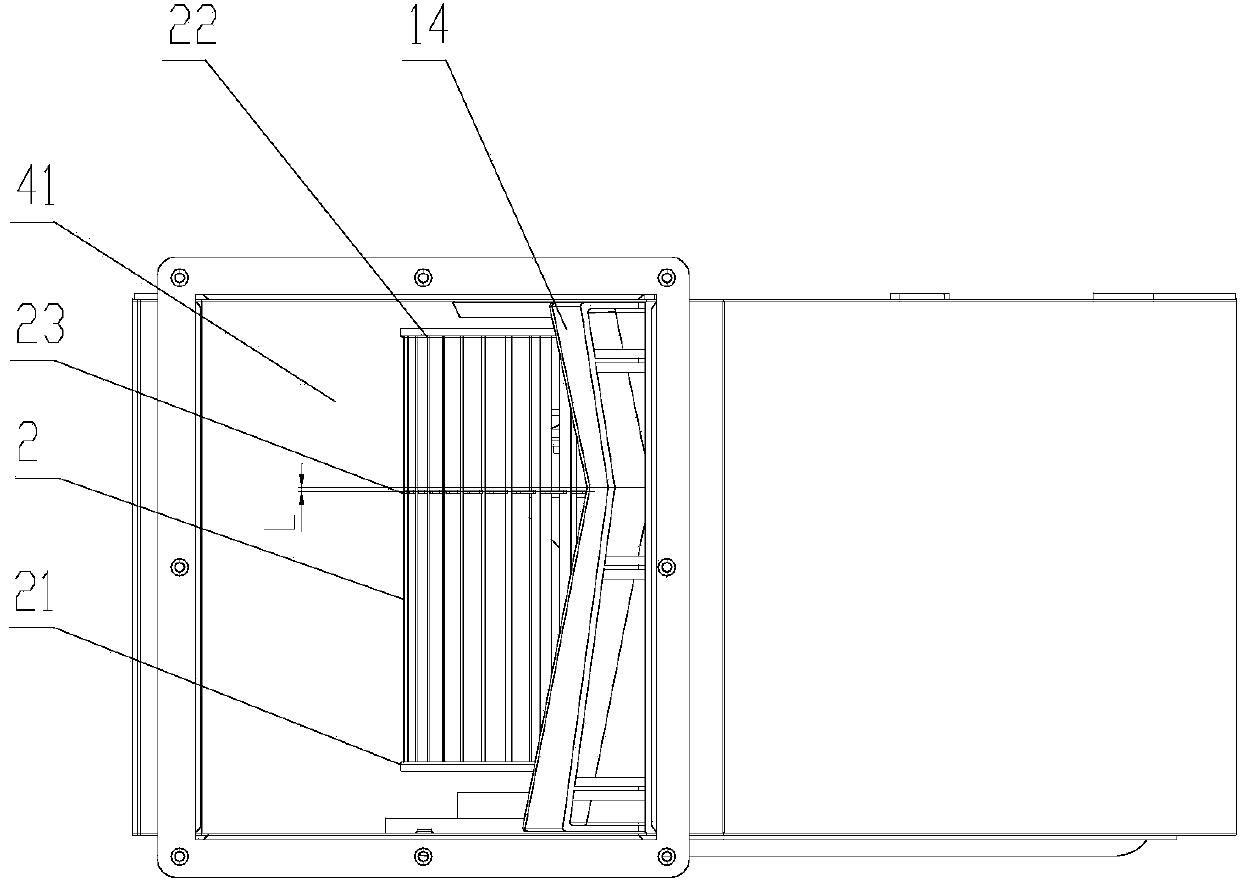

[0029] The double-inlet centrifugal fan of the present invention is as Figures 1 to 7 As shown, it includes a volute 1, a double air inlet impeller 2 and a motor 3, the double air inlet impeller 2 is installed on the rotating shaft of the motor 4 and placed in the volute 1, and the motor 4 is fixed 6 in the volute 1 by the motor fixing bracket , the volute 1 includes a front cover 11, a rear cover 13 and a volute coaming 12 placed between the front cover 11 and the rear cover 13, the front cover 11 is aligned with the double inlet impeller 2 The position is provided with a forward air passage 40, and the rear cover 13 is provided with a rear air inlet passage 42 at the position facing the double air inlet impellers 2. 12 is provided with an air outlet channel 41, and a volute flange 15 is provided at the air outlet port of the air outlet channel 41, and the front cover 11, the volute coaming 12 and the rear cover 13 are close to the air outlet of the air outlet channel 41. T...

Embodiment 2

[0034] The double-inlet centrifugal fan of this embodiment is similar to Embodiment 1, and the difference is that, as shown in 8 to 10, the above-mentioned volute tongue curved surface 142 is a concave arc-shaped curved surface, and the front edge of the volute tongue curved surface 142 is in contact with the fixed surface The distance of 144 is greater than the distance between the rear end edge of the curved surface 142 of the volute tongue and the fixed surface 144, that is, the height of the front end surface 141 of the volute tongue is greater than the height of the rear end surface 143 of the volute tongue, so that the curved surface 142 of the volute tongue is in a state of non-middle symmetry, which is beneficial to Improve the air volume, wind pressure and efficiency, and also achieve a better effect of reducing rotational noise.

[0035] The working principle of the double-inlet centrifugal fan in this embodiment is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com