Counter-rotating fan

A technology of rotary fan and rotation axis, which is applied in the field of fan equipment, can solve the problems of change of inflow attack angle, periodic pulsation of pressure distribution on the surface of the second-stage blade, loud noise, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

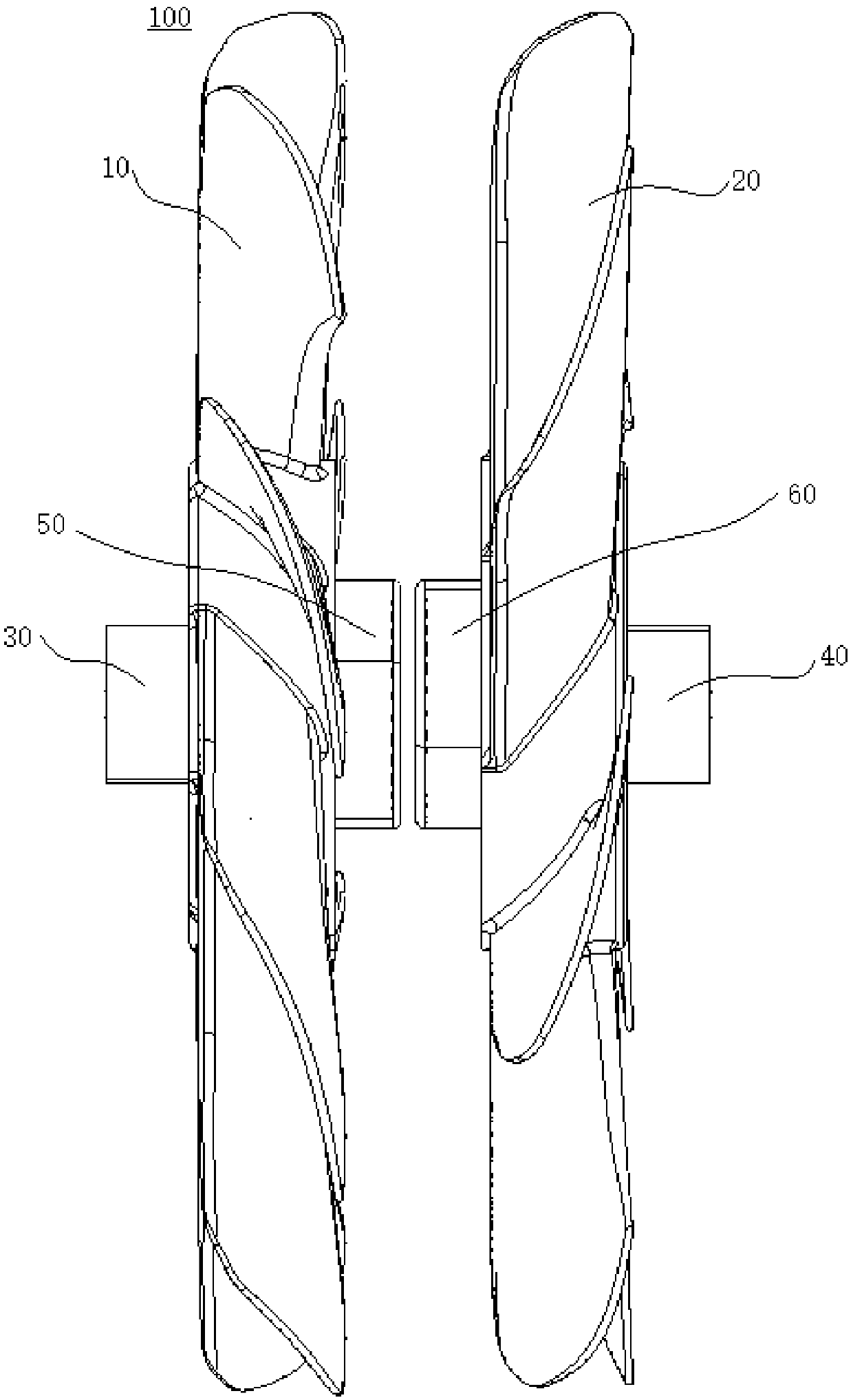

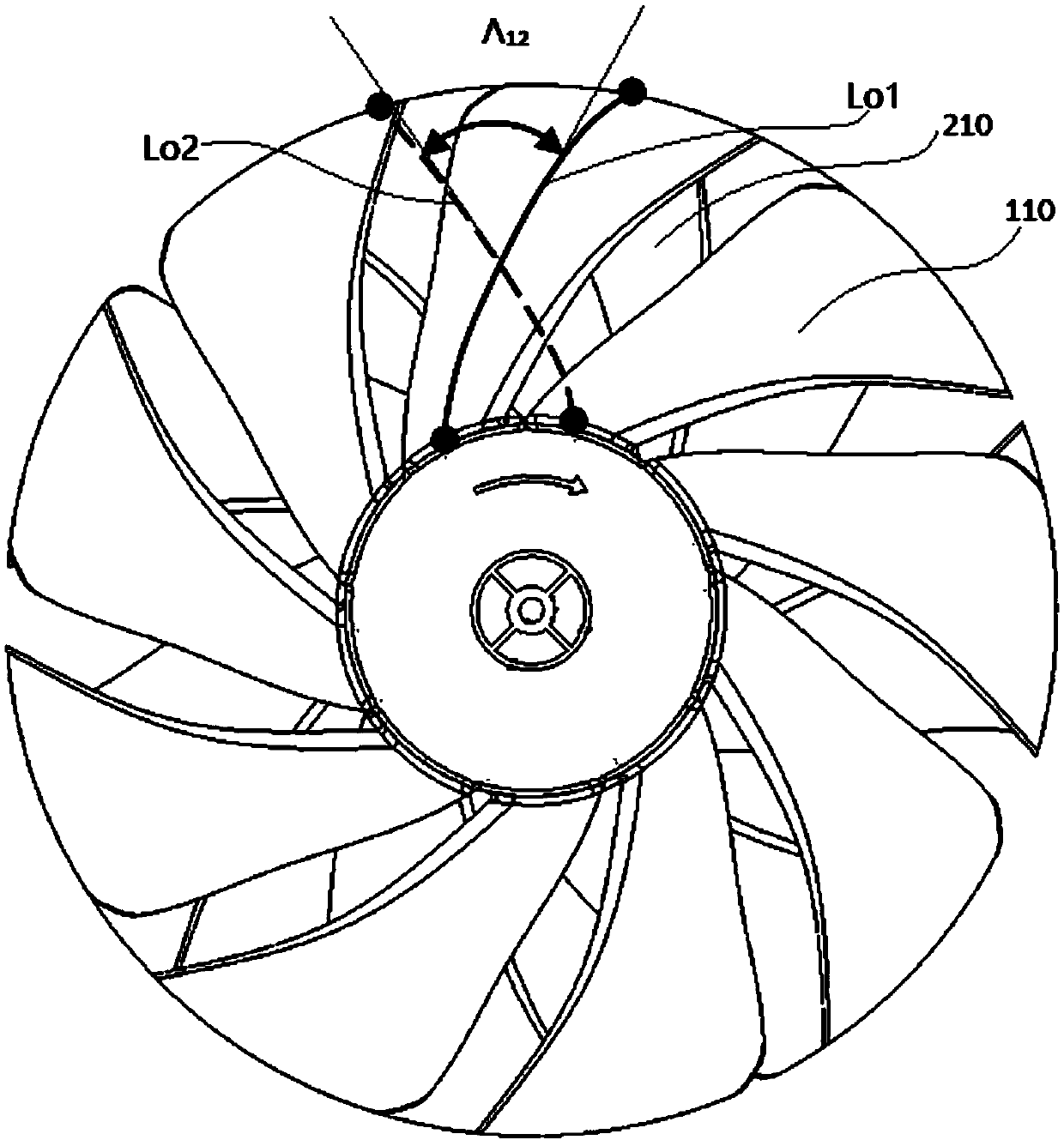

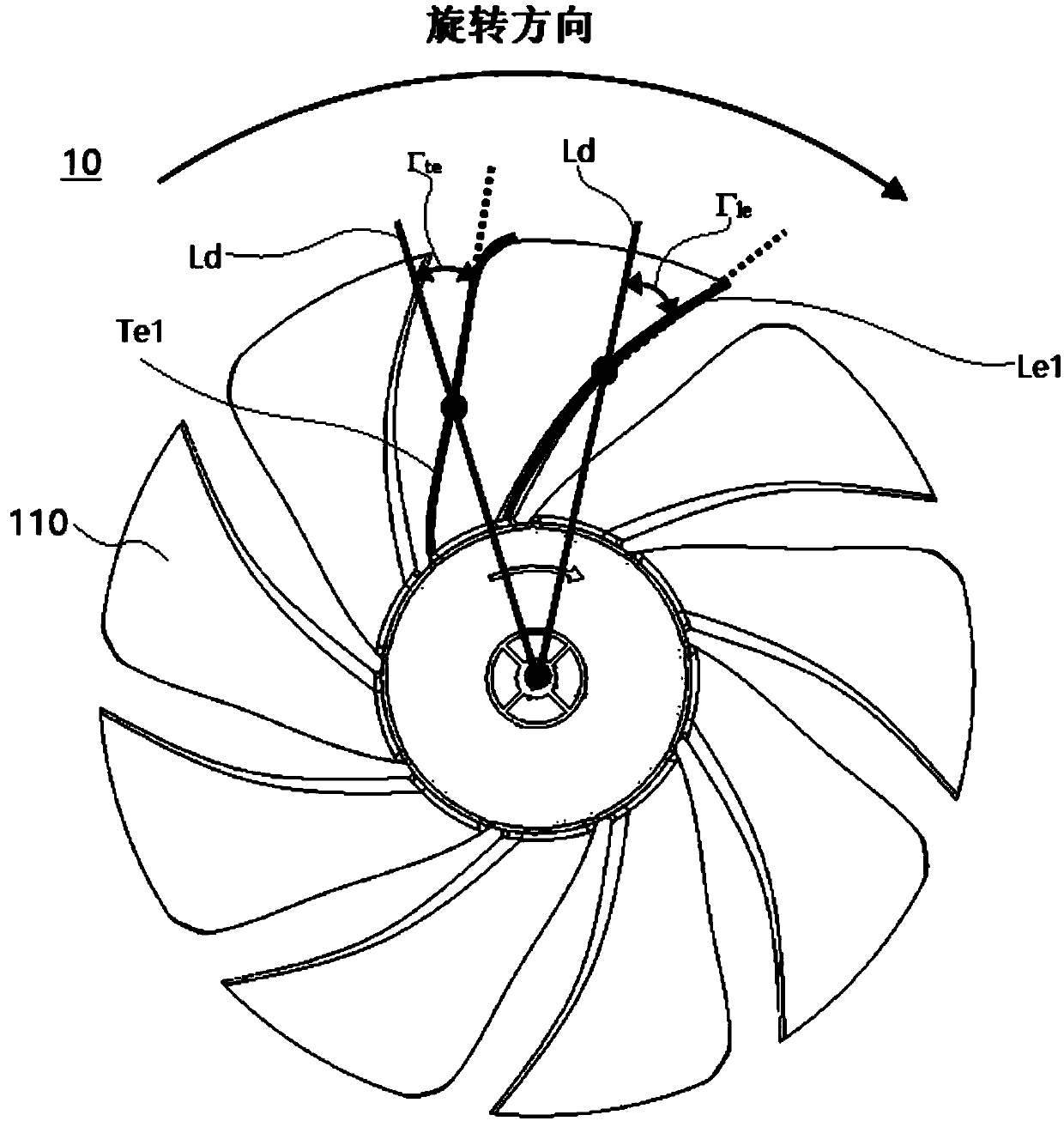

[0055] The counter-rotating fan 100 of this embodiment includes a first stage impeller 10 , a second stage impeller 20 , a first locking nut 30 , a second locking nut 40 , a first driving motor 50 and a second driving motor 60 . The first-stage impeller 10 and the second-stage impeller 20 are coaxial and spaced apart. The first locking nut 30 locks the first-stage impeller 10 on the first drive motor 50, and the second locking nut 40 locks the second-stage The impeller 20 is locked on the second driving motor 60 . The rotation directions of the first-stage impeller 10 and the second-stage impeller 20 are opposite. The first-stage impeller 10 includes a plurality of first blades 110 arranged in the circumferential direction. A leading edge Le1 and a first trailing edge Te1, both of the first leading edge Le1 and the first trailing edge Te1 are curved toward the direction of rotation in a radial direction from inside to outside, and the curved protrusion of the first leading edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com