Dual-blade denoising blower fan

A dual-blade, noise reduction technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as environmental noise pollution, strong noise, etc., and achieve the effect of reducing rotational noise, improving efficiency, and smoothing speed distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

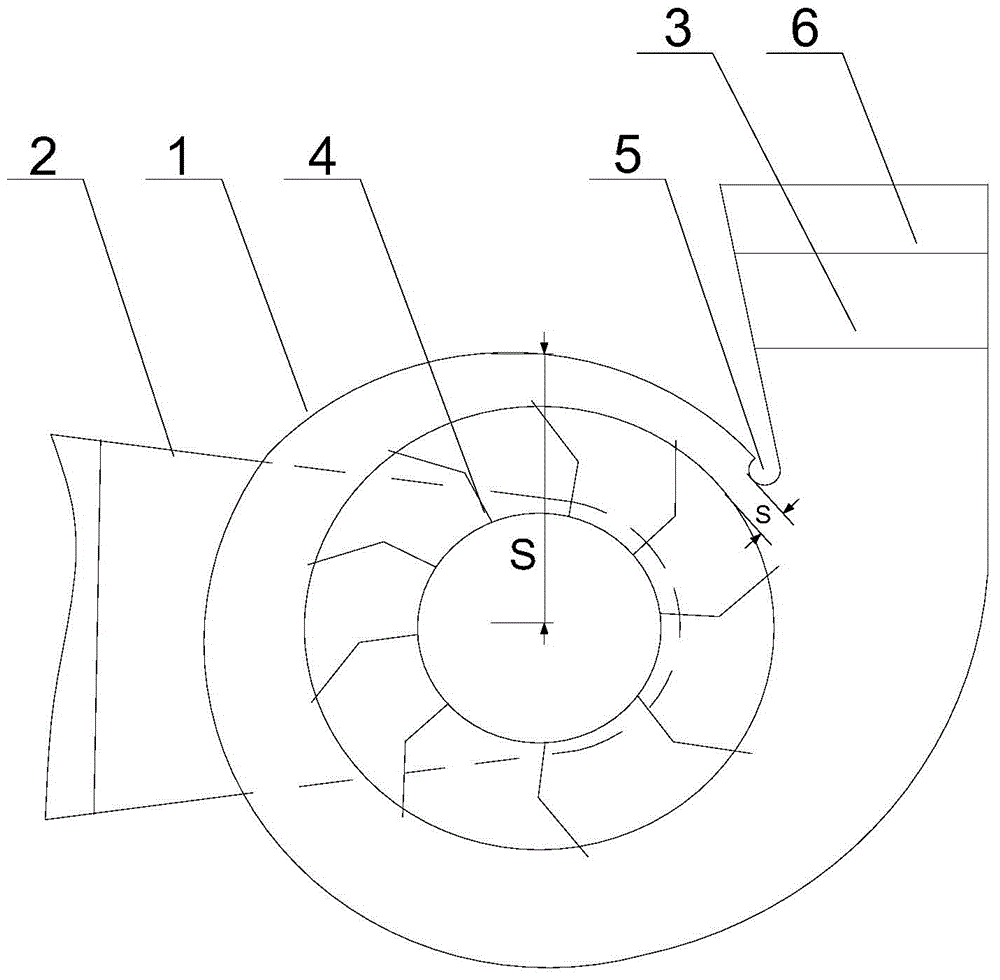

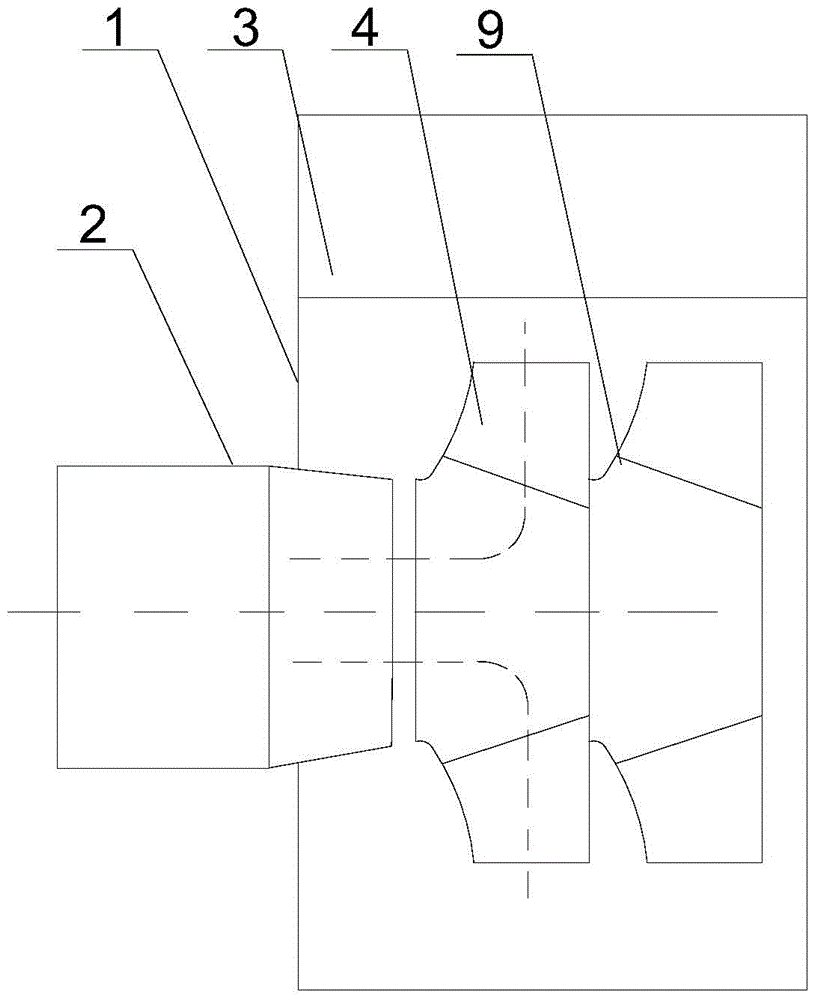

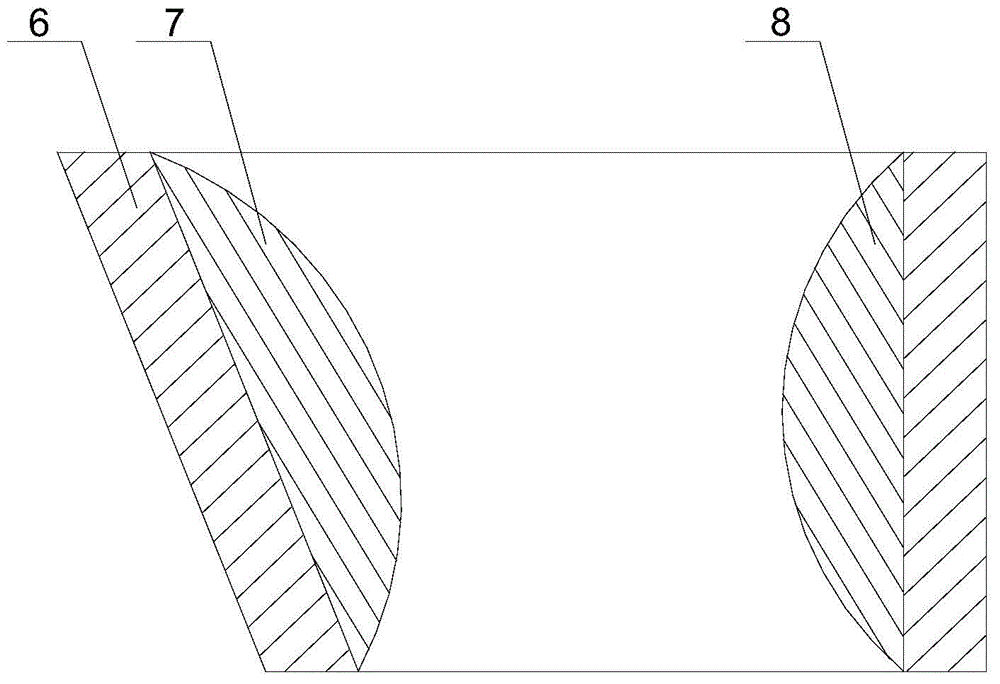

[0024] Such as Figure 1 to Figure 3 As shown, this embodiment includes a volute 1 and a first impeller 4 fixed in the volute 1, and the two sides of the volute 1 are respectively provided with a horizontal air inlet 2 and a vertical air outlet 3. A volute tongue 5 is arranged between the volute 1 and the air outlet 3, and a muffler tube 6 is threadedly connected to the end of the air outlet 3, and on the half inner wall of the muffler tube 6 on the side close to the volute tongue 5 A first sound-absorbing member 7 is installed, and a second sound-absorbing member 8 is fixed on the remaining half of the inner wall of the sound-absorbing cylinder 6. The longitudinal sections of the first sound-absorbing member 7 and the second sound-absorbing member 8 are arc-shaped, and The distance between the highest point of the first silencing element 7 and the inner wall of the silencing cylinder 6 is A, and the distance between the highest point of the second silencing element 8 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com