On-line rheological adjustment device and adjustment process of unpowered deep cone thickener

A deep cone thickening and adjusting device technology, which is applied to the feeding/discharging device, separation method, sedimentation and separation of the settling tank, etc., can solve the problems of poor rheological properties of slurry, slurry wall hanging, etc., and achieve rheological improvement , improve vibration efficiency, and solve the effect of slurry hanging on the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

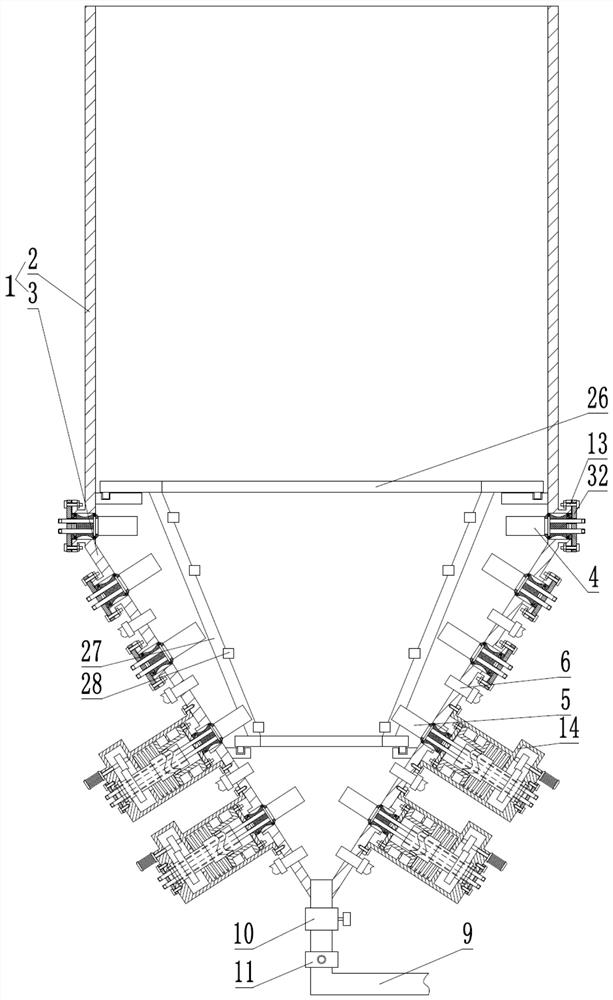

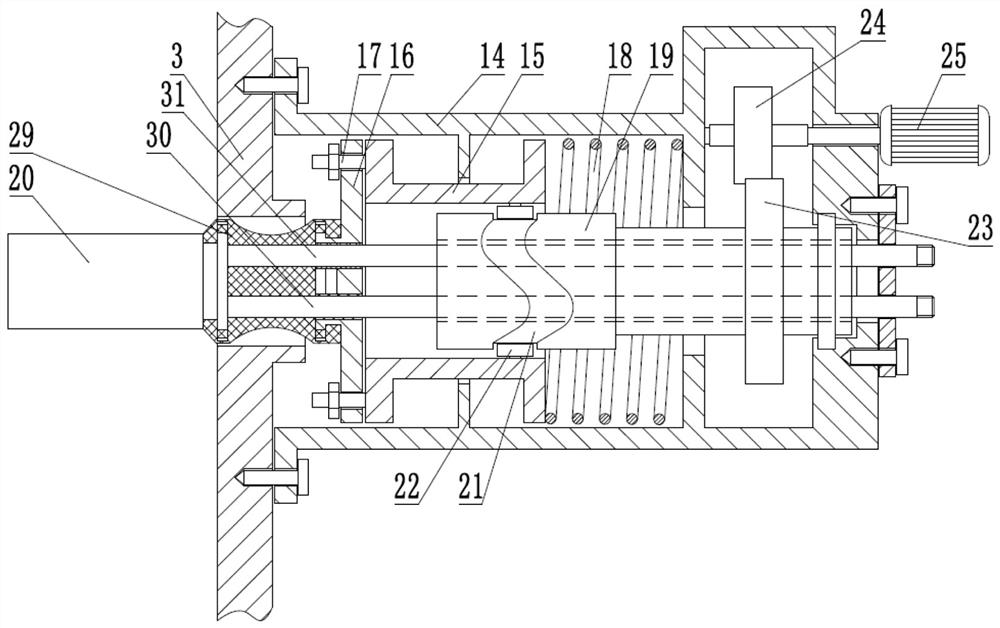

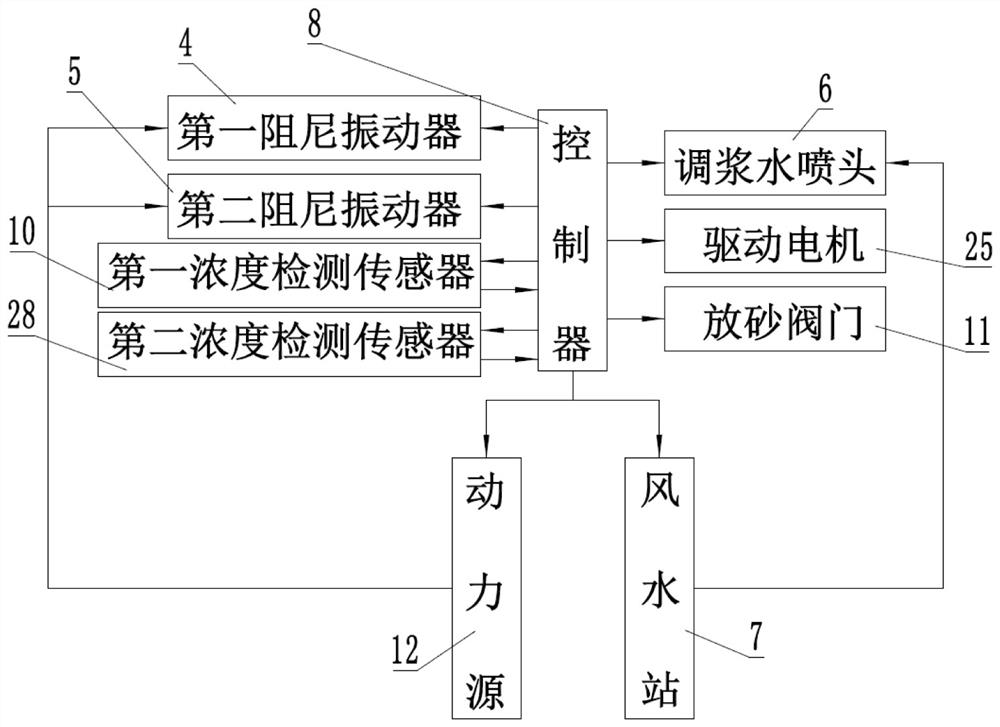

[0034] Such as Figure 1-Figure 3 Commonly shown, the non-powered deep cone thickener rheological on-line adjustment device includes a sand bin 1, and the sand bin 1 includes a straight barrel section 2 and a cone barrel section 3 arranged up and down, and the lower end of the straight barrel section 2 and the upper end of the cone barrel section 3 Several first damping vibrators 4 are installed on the warehouse wall, and several second damping vibrators 5 are installed on the warehouse wall at the lower end of the cone section 3, and each second damping vibrator 5 and the warehouse of the cone section 3 A position adjustment mechanism is arranged between the walls, and a number of mixing water nozzles 6 are installed on the warehouse wall of the cone section 3, and the position of each mixing water nozzle 6 is consistent with the first damping vibrator 4 and the second damping vibrator. The position of the vibrator 5 is corresponding, and all the mixing water nozzles 6 are co...

Embodiment 2

[0048] The rheological on-line adjustment process of the unpowered deep cone thickener includes the following steps:

[0049] S1. The settled mortar enters the lower end of the straight barrel section 2 and the cone section 3 of the sand bin 1, and the controller 8 controls the first damping vibrator 4 and the second damping vibrator 5 to start to drive the mortar to vibrate to avoid the mortar hanging wall.

[0050]S2. After the first concentration detection sensor 10 detects that the concentration of the mortar reaches a predetermined value, the controller 8 controls the sand discharge valve 11 to open, and the mortar in the cone section 3 is discharged from the sand bin 1 through the sand discharge pipe 9 .

[0051] S3. The second concentration detection sensor 28 monitors the concentration of the mortar in the cone section 3 in real time, and controls the opening and closing of the mixing water nozzle 6 and the position adjustment mechanism according to the monitored conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com