Binding bag bottom dust removal filter bag with protection structure

A technology to protect the structure and buckle the bag, which is applied in the filtration of dispersed particles, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of the filter bag being unable to continue to undertake the filtration work, the wear and tear of the filter material at the bottom of the bag, and the fatigue damage. The effect of solving the problems of wear damage and fatigue damage and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025]Example 1

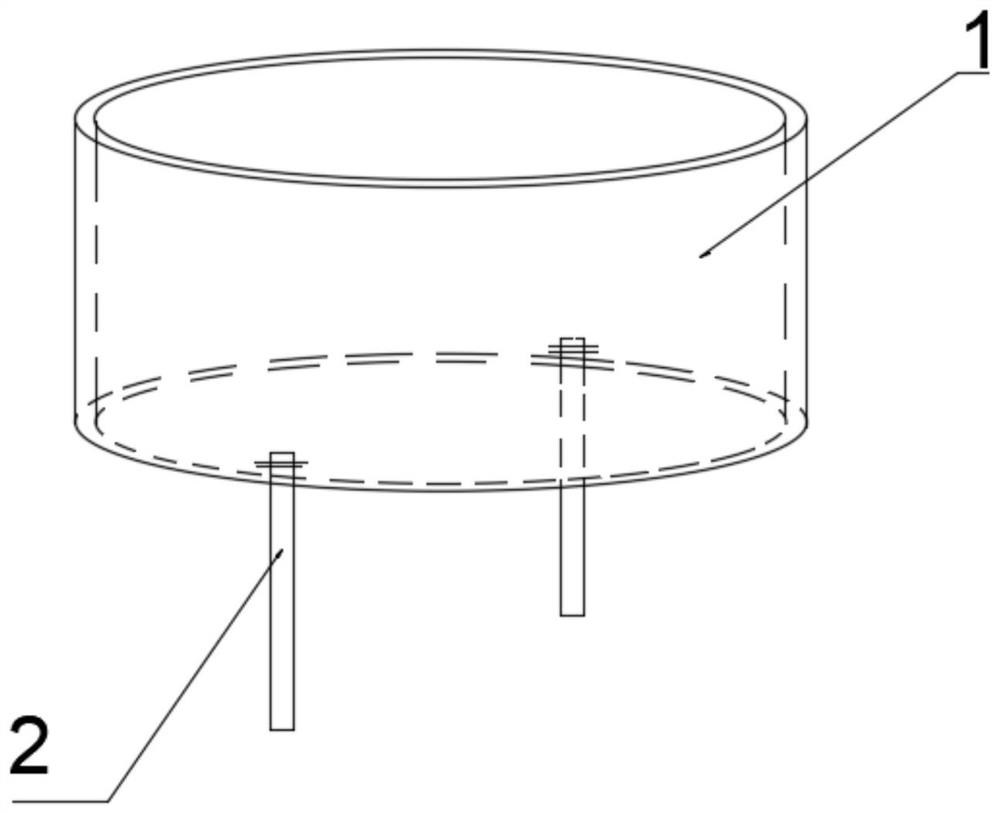

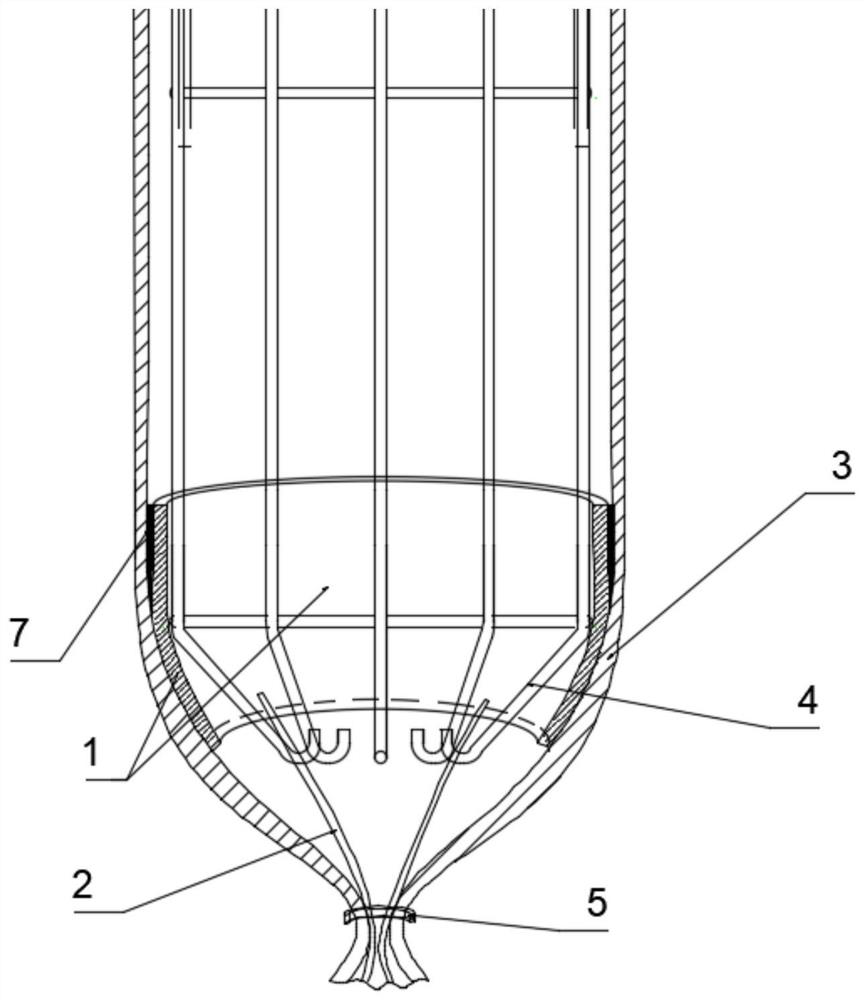

[0026]An additional layer of protective material 1 is added inside the bottom of the part filter bag. Such asfigure 1 As shown, the protective material 1 is made of a filter material that produces a dust filter bag, and the protective material 1 is made as a cylindrical shape, and the cylindrical diameter of the protective material 1 is slightly smaller than the filter bag cylindrical bag diameter, and the protective material 1 is in the dust filter bag. The height in the axial direction of the cylindrical bag is 10 cm. Two connecting belts 2 are sewn on the protective material 1, and the connecting belt 2 is made of filter material. The adhesive gel 7 is applied to the protective material 1, and the protective material 1 applied after the adhesive glue 7 is placed inside the bottom of the cylindrical bag that has not been raised, and the protective material 1 and the bottom of the bag are pressed. The inner filter is fixed. ,

[0027]Then use the connection belt 2 with ...

Example Embodiment

[0029]Example 2

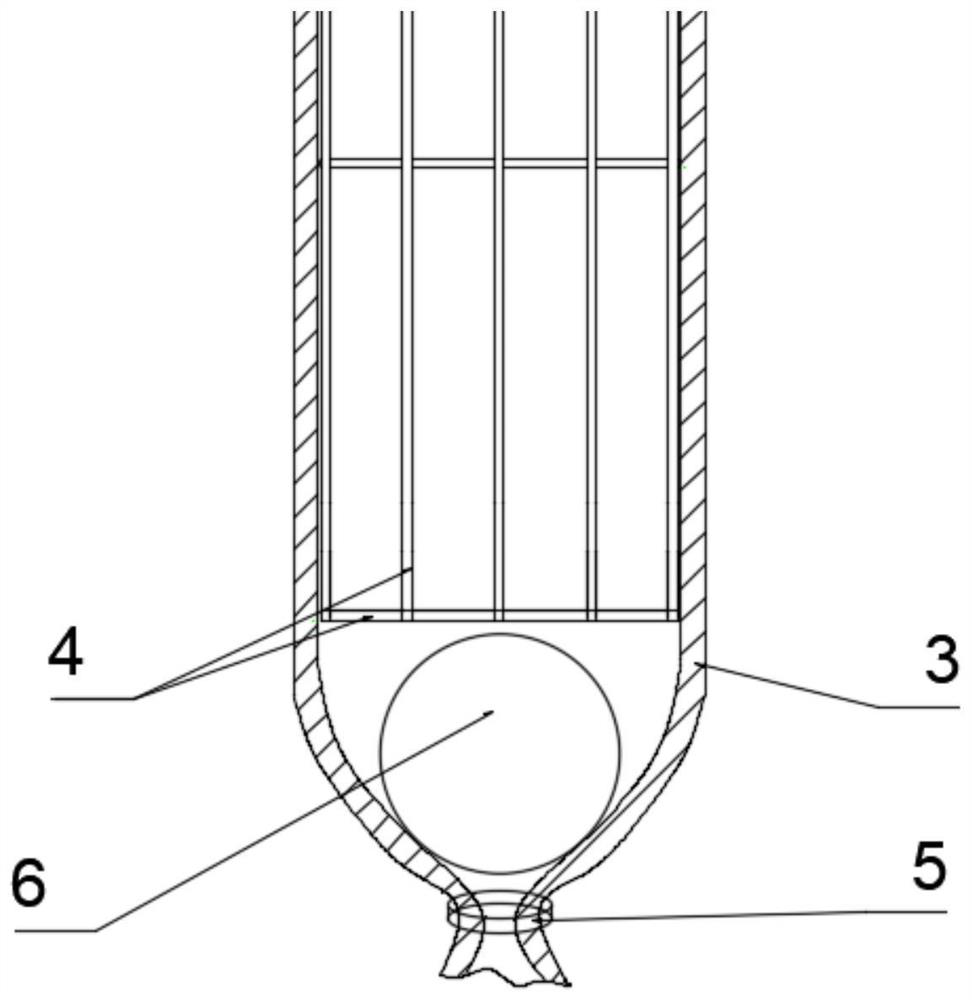

[0030]Such asimage 3 As shown, the filler 6 is provided inside the bottom of the bag, and the filler 6 is a hollow plastic ball product, and places it in the bottom of the bag under the bottom of the dust filter bag, and then loads the conventional flat bag cage 5. After adding the filler 6, the filter bag is in the filtration and spraying, the contact friction problem between the bottom and the bag cage is weakened, and the bag bottom filter is effectively removed, and the bag bottom filter is prevented. The bending causes fatigue damage, producing a damaged opening and cannot continue to undertake the problem of filtration work, and effectively extend the life of the filter bag.

Example Embodiment

[0031]Example 3

[0032]With the example 2, the distinction between the filler 6 in Example 3 was composed of a waste filter material that produced a dust filter bag, by 8 cord bundle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com