Cracking reaction kettle

A technology of cracking reaction and reactor, which is applied in the field of cracking reactor, which can solve the problems of discharge blockage, material hanging on the wall, temperature control, etc., and achieve the effect of saving time, increasing reaction time and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

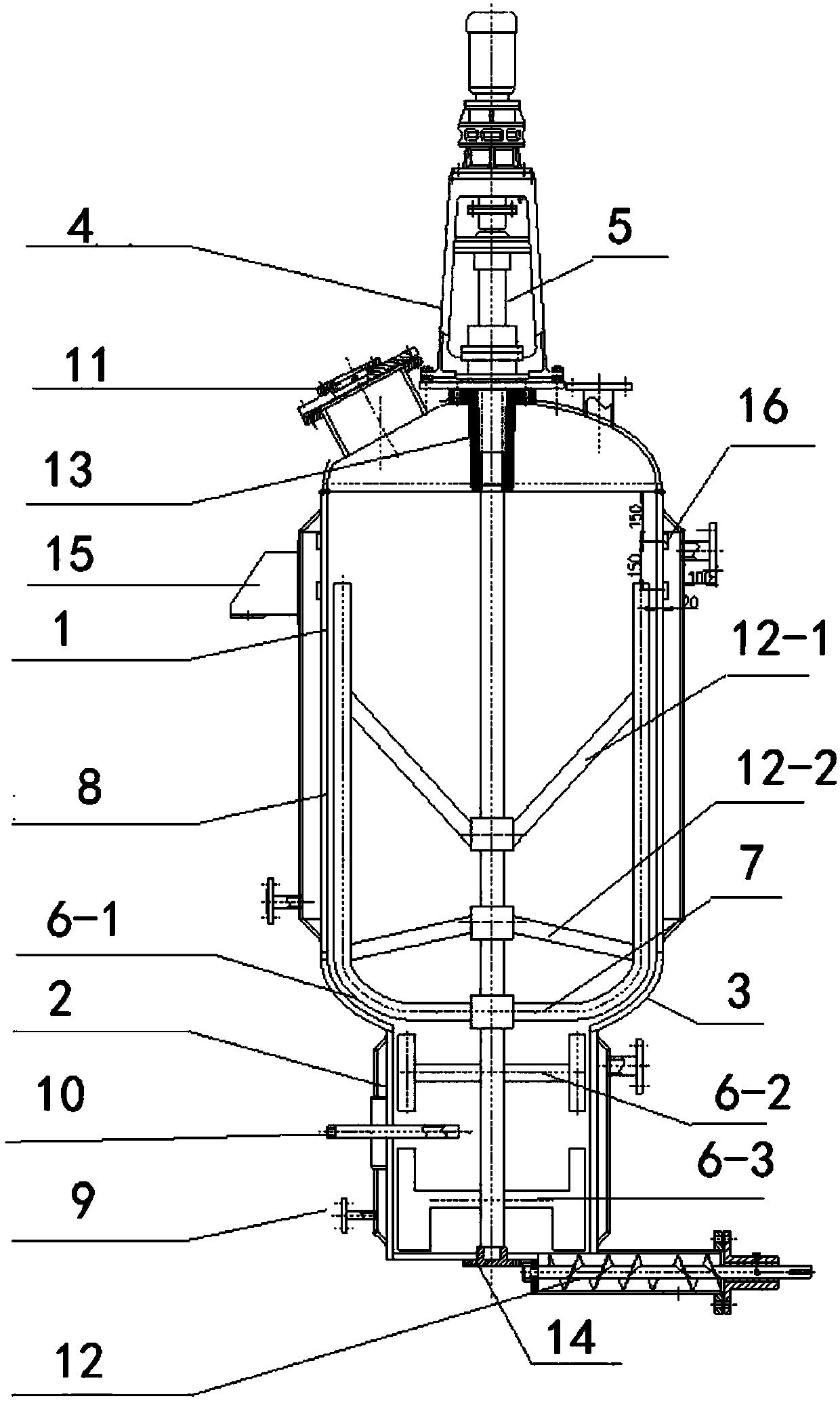

[0017] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

[0018] With reference to accompanying drawing, a kind of cracking reactor comprises reactor large cylinder 1 and reactor small cylinder 2, and the diameter of described reactor large cylinder 1 is greater than described reactor small cylinder 2, and described reactor large cylinder 1 The lower part is connected to the small cylinder body 2 of the reaction kettle through an elliptical head 3; the large cylinder body 1 of the reaction kettle is provided with a transmission device 4, and the transmission shaft 5 of the transmission device 4 extends into the large cylinder body of the reaction kettle and In the small cylinder of the reaction kettle, the transmission shaft 5 in the large cylinder 1 of the reactor is provided with a first stirring device 6-1, and the first stirring device 6-1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com