Method of hydrogenating liquefied petroleum gas to prepare ethylene cracking feed

A technology for liquefied petroleum gas and ethylene cracking, which is applied in the petroleum industry, hydrotreating process, and hydrocarbon oil treatment. The effect of the operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

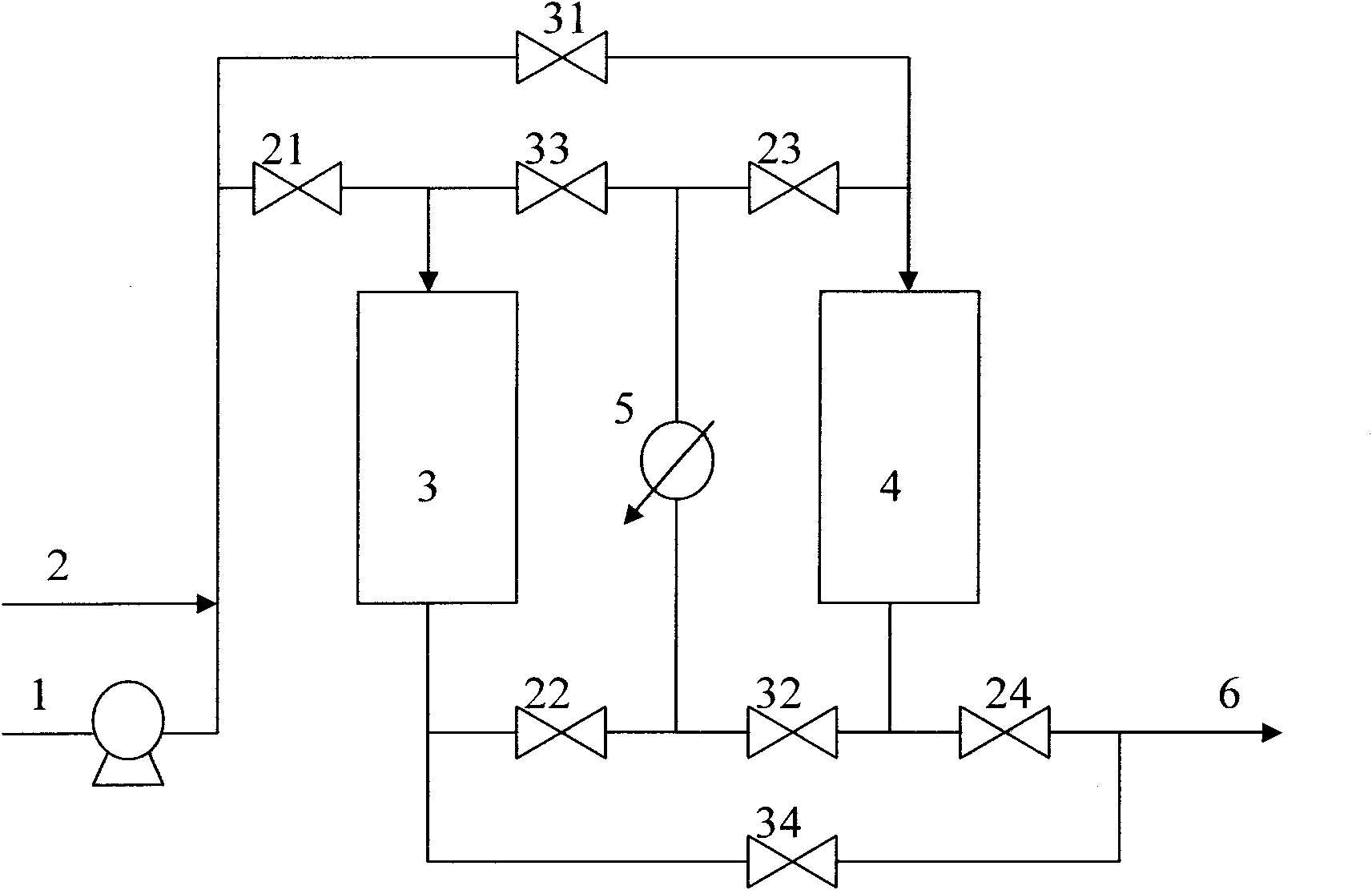

[0032] Take 100ml of FH-40C catalyst, and put it into two stainless steel reactors with an inner diameter of 25mm and a length of 1200mm. Reaction raw materials: hydrogen is electrolytically purified hydrogen with a purity >99%; the C4 fraction is obtained from Fushun Petroleum No. 2 Plant, and its composition is shown in Table 3. The reaction is upper feed, the reaction material flows out from the bottom of the reactor, and enters the separator after cooling, the tail gas is discharged from the top of the separator, the liquid phase at the bottom is regularly sampled, and the composition is analyzed by gas chromatography. During normal operation, the reaction material first enters the first reaction section 3, and then enters the second reaction section 4. The operation mode of the valves is: 21, 22, 23, 24 are opened, and 31, 32, 33, 34 are closed. The specific reaction conditions and results are listed in Table 4.

[0033] Table 3 Composition of industrial carbon four frac...

Embodiment 1

[0039] The stability experiment of embodiment 1. When the reaction temperature rise in the first stage drops by 10°C (that is, when the reaction temperature rises to 110°C), the operation of the first reaction stage and the second reaction stage is switched, that is, the reaction materials enter the second reaction stage first, and then enter the first reaction stage. In the reaction section, other operating conditions remain unchanged, and the operation mode of the valve is: 21, 22, 23, and 24 are closed, and 31, 32, 33, and 34 are opened. At this time, the temperature rise of the reaction section that is first in contact with the reaction material returns to 120°C, while the second reaction section (originally the first reaction section) has a low total temperature rise and a high inlet temperature, so the reaction can still be achieved without raising the temperature. Requirements, that is, without other changes, the recovery of the activity of the reaction system can be re...

Embodiment 3

[0043] The stability experiment of embodiment 3. When the temperature rise of the first stage of reaction drops by 30°C (that is, when the reaction temperature rises to 110°C), the operation of the first reaction stage and the second reaction stage is switched, that is, the reaction material enters the second reaction stage first, and then enters the first reaction stage. In the reaction section, other operating conditions remain unchanged. At this time, the temperature rise of the reaction section that is in contact with the reaction material first returns to 130°C, and the reaction control index can be reached by only increasing the reaction temperature by 2°C in both reaction sections.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com