Liquefied gas treatment system for vessel

a gas treatment system and liquefied gas technology, applied in the direction of vessel parts, combustion air/fuel air treatment, liquid fuel feeders, etc., can solve the problems of large amount of power consumption, complicated control of the entire system, and bog burning in gas combustion units (gcus) or in atmosphere, so as to save initial installation cost and operation cost, reduce the amount of bog consumed in gcus or the like, and save energy consumption in the reliquefaction apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

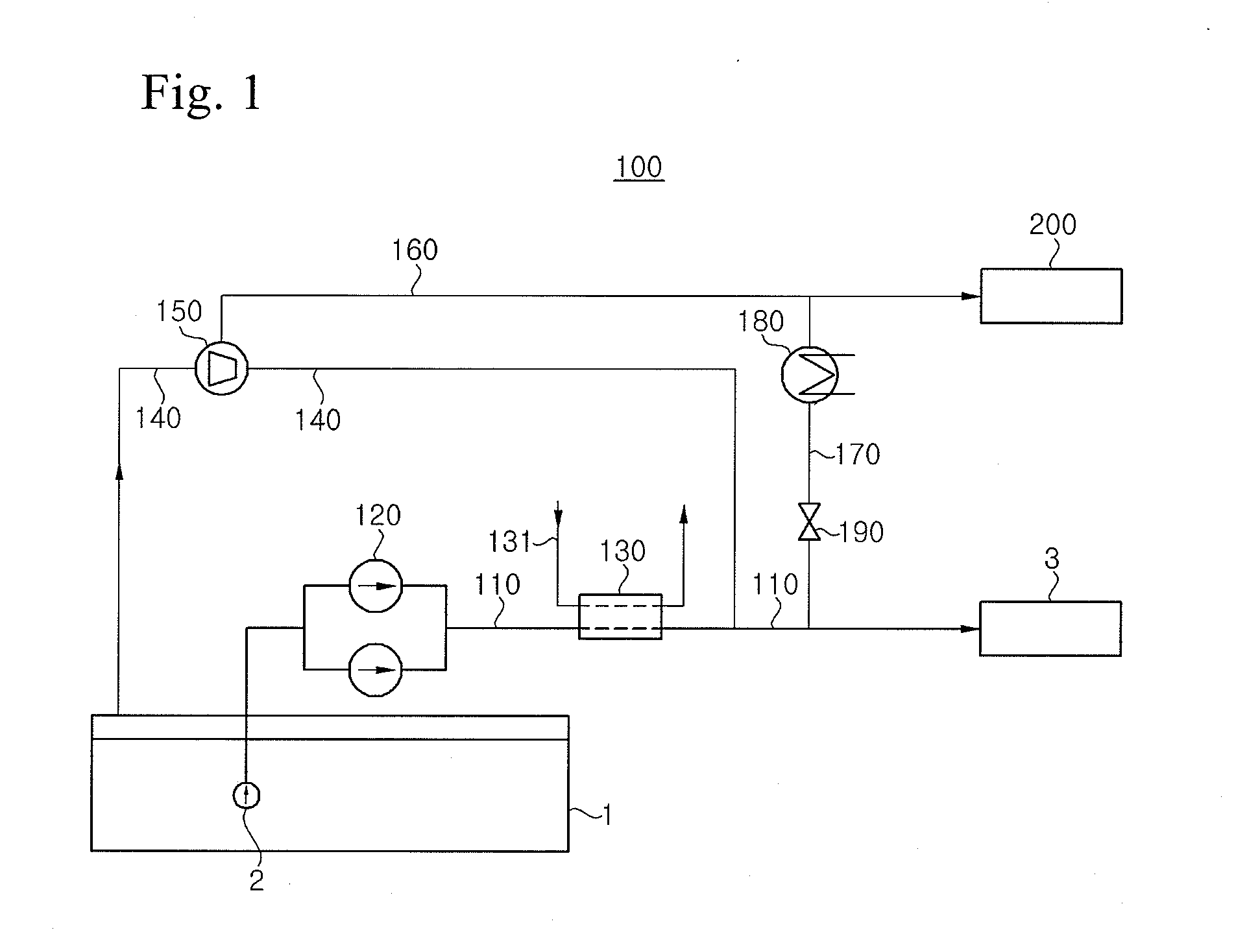

[0055]FIG. 1 is a configuration diagram illustrating a liquefied gas treatment system for a vessel according to the present invention. The liquefied gas treatment system of the present embodiment may be applied to an LNG carrier equipped with an ME-GI engine as a main propulsion engine (that is, propulsion means using LNG as fuel).

[0056]Referring to FIG. 1, the liquefied gas treatment system 100 according to the present embodiment includes a fuel supply line 110 and a BOG line 140. The fuel supply line 110 is configured to provide a passage for transferring LNG from a cargo tank 1 to a main engine 3 as a propulsion system. The BOG line 140 is configured to provide a passage for transferring BOG generated from the cargo tank 1 to the main engine 3. In addition, the liquefied gas treatment system 100 using BOG according to the present embodiment supplies LNG to the main engine 3 as fuel through the fuel supply line 110 by an LNG pump 120 and an LNG vaporizer 130, supplies BOG to the m...

second embodiment

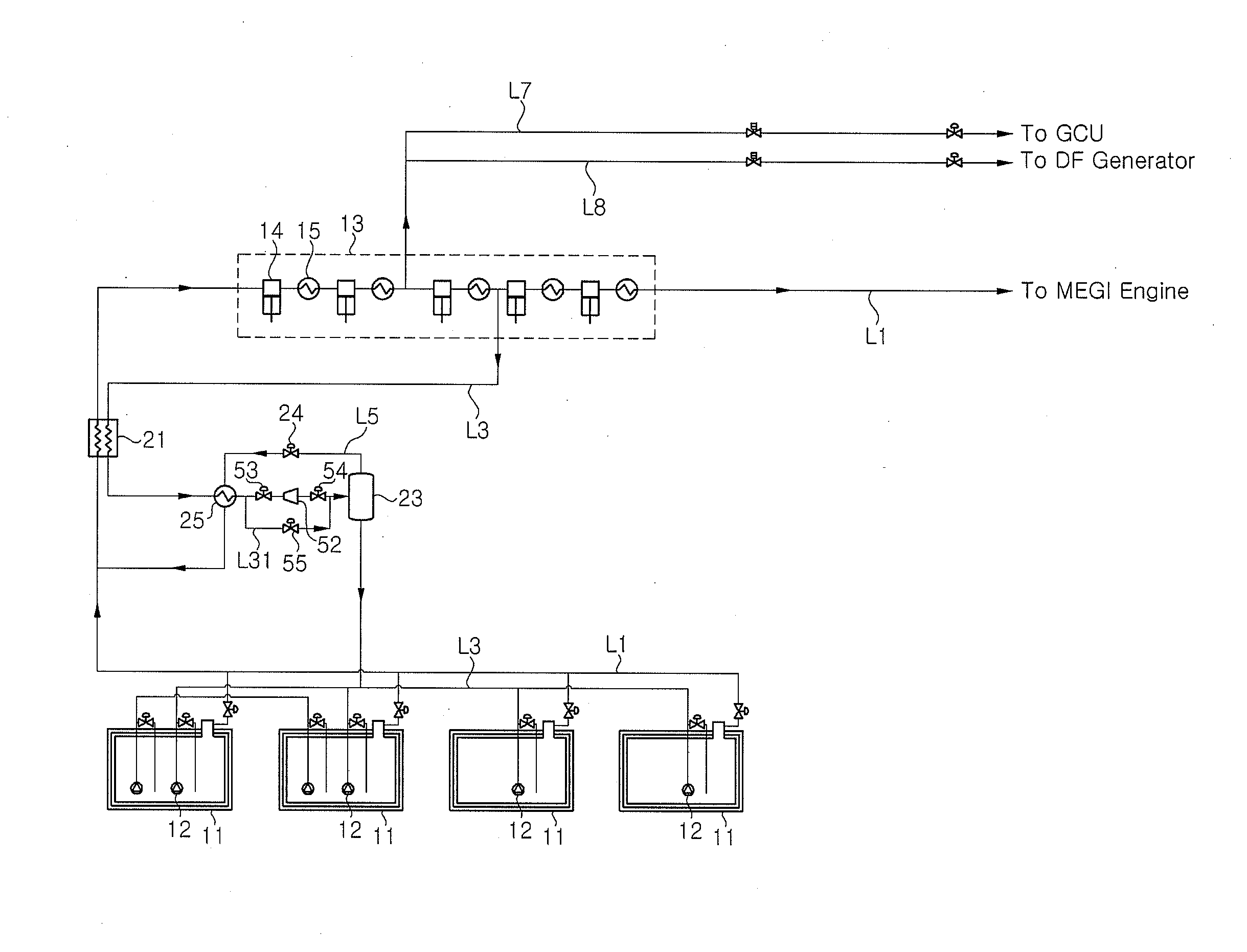

[0070]FIG. 2 is a schematic configuration diagram illustrating a liquefied gas treatment system for a vessel according to the present invention.

[0071]Although FIG. 2 illustrates an example in which the liquefied gas treatment system of the present invention is applied to an LNG carrier equipped with a high pressure natural gas injection engine capable of using natural gas as fuel (that is, propulsion means using LNG as fuel), the liquefied gas treatment system of the present invention can also be applied to any type of vessels (LNG carrier, LNG RV, and the like) and marine plants (LNG FPSO, LNG FSRU, BMPP, and the like), in which a liquefied gas cargo tank is installed.

[0072]In the liquefied gas treatment system for the vessel according to the second embodiment of the present invention, NBOG generated and discharged from a cargo tank 11 storing liquefied gas is transferred along a BOG supply line L1, is compressed in a compressor 13, and is then supplied to the high pressure natural...

third embodiment

[0092]FIG. 5 is a schematic configuration diagram illustrating a liquefied gas treatment system for a vessel according to the present invention.

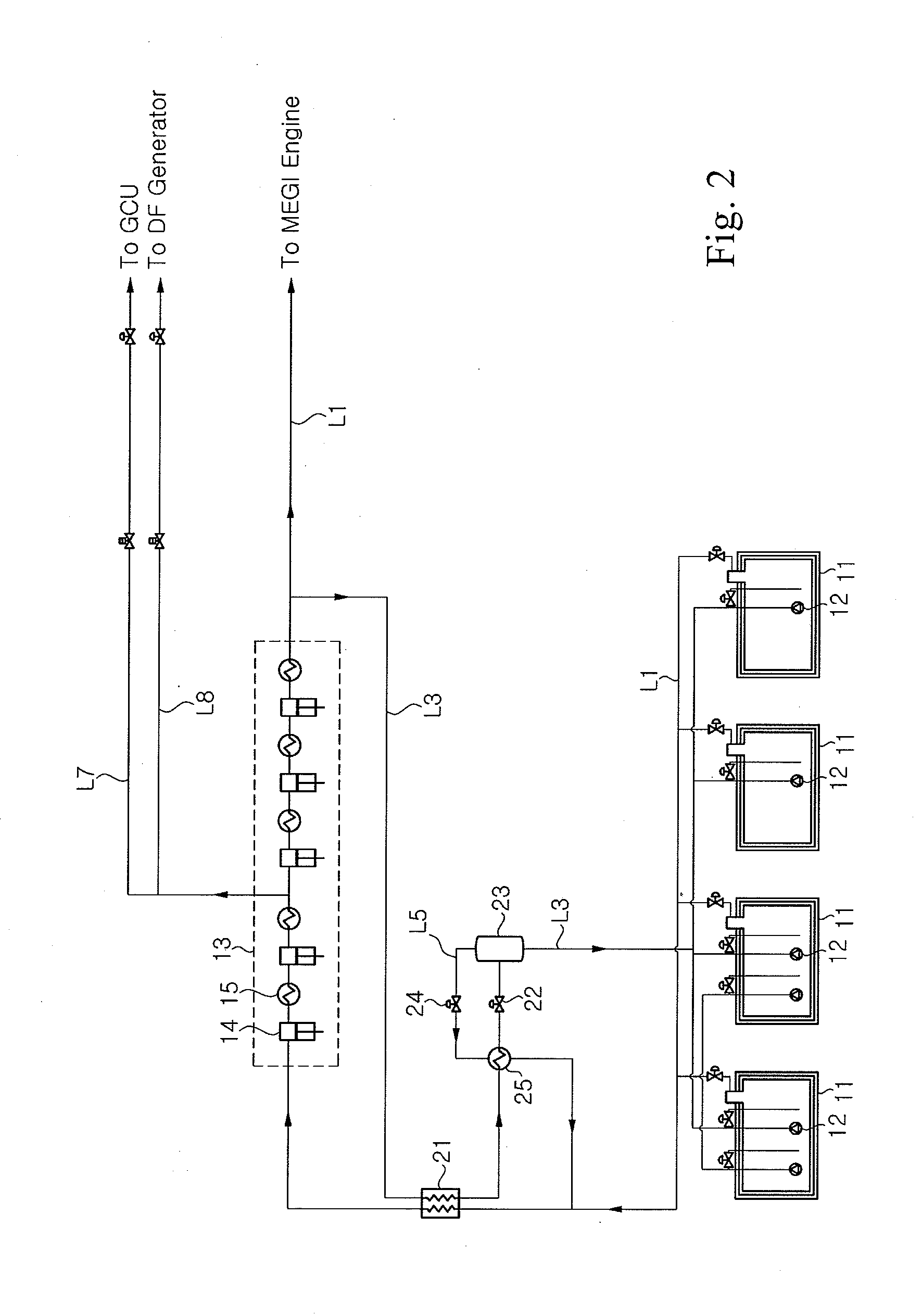

[0093]The liquefied gas treatment system according to the third embodiment differs from the liquefied gas treatment system according to the second embodiment in that LNG can be used after forcible vaporization when an amount of BOG necessary for the ME-GI engine or the DF generator is larger than an amount of BOG generated naturally in the cargo tank 11. Hereinafter, only a difference from the liquefied gas treatment system of the second embodiment will be described in more detail. In addition, the same reference numerals are assigned to the same elements as those of the second embodiment, and a detailed description thereof will be omitted.

[0094]The liquefied gas treatment system for the vessel according to the third embodiment of the present invention is identical to that according to the second embodiment in that NBOG generated and dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com