Skid-mounted decompression system

A technology of system application and mechanical control system, which is applied in the field of coal chemical and petrochemical equipment, can solve the problem of wear and tear. It takes a few hours and a few months at the longest to perform switching maintenance, large safety hazards, and high maintenance costs. Achieve high degree of automation, reduce cracking, high reliability and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

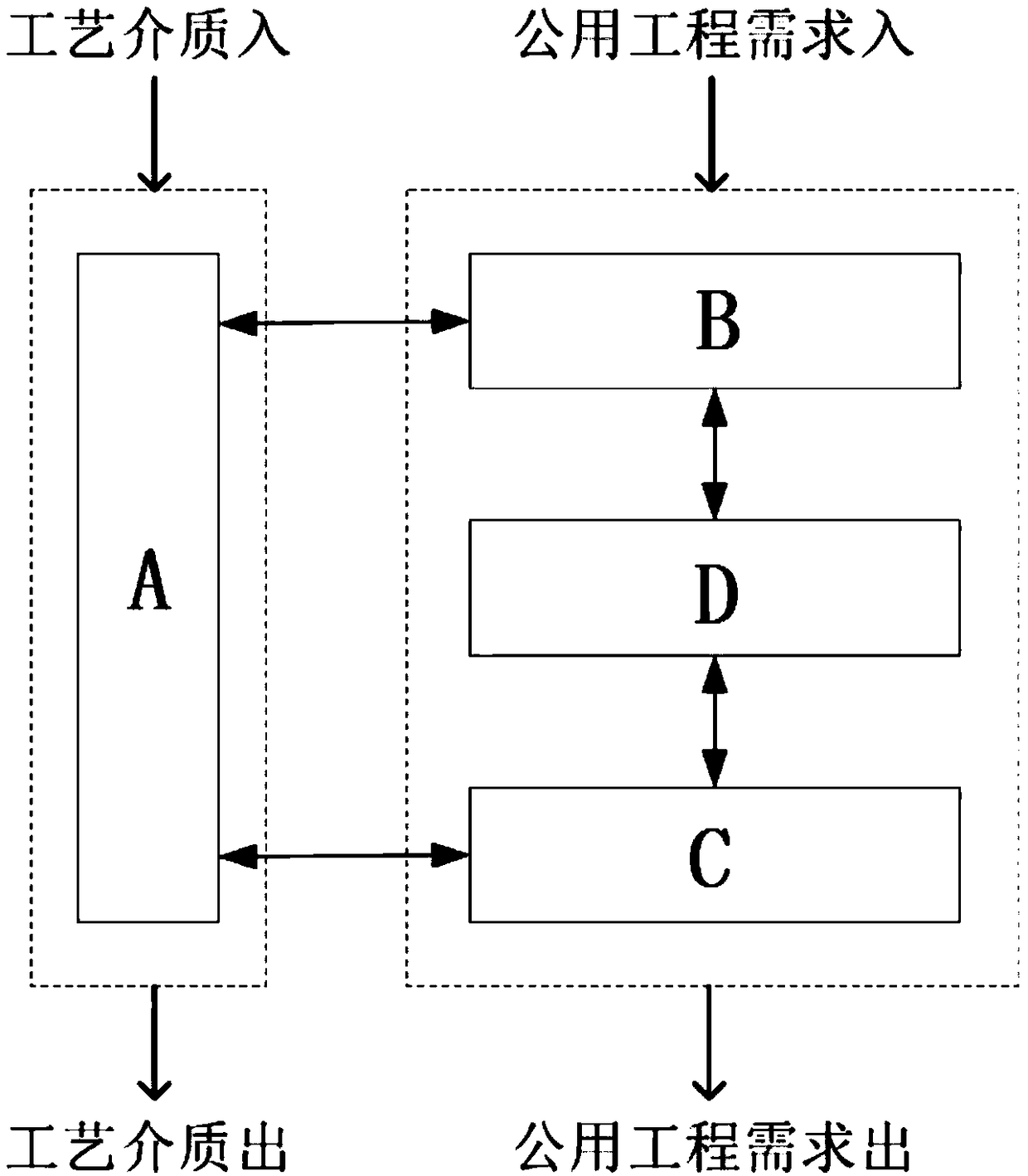

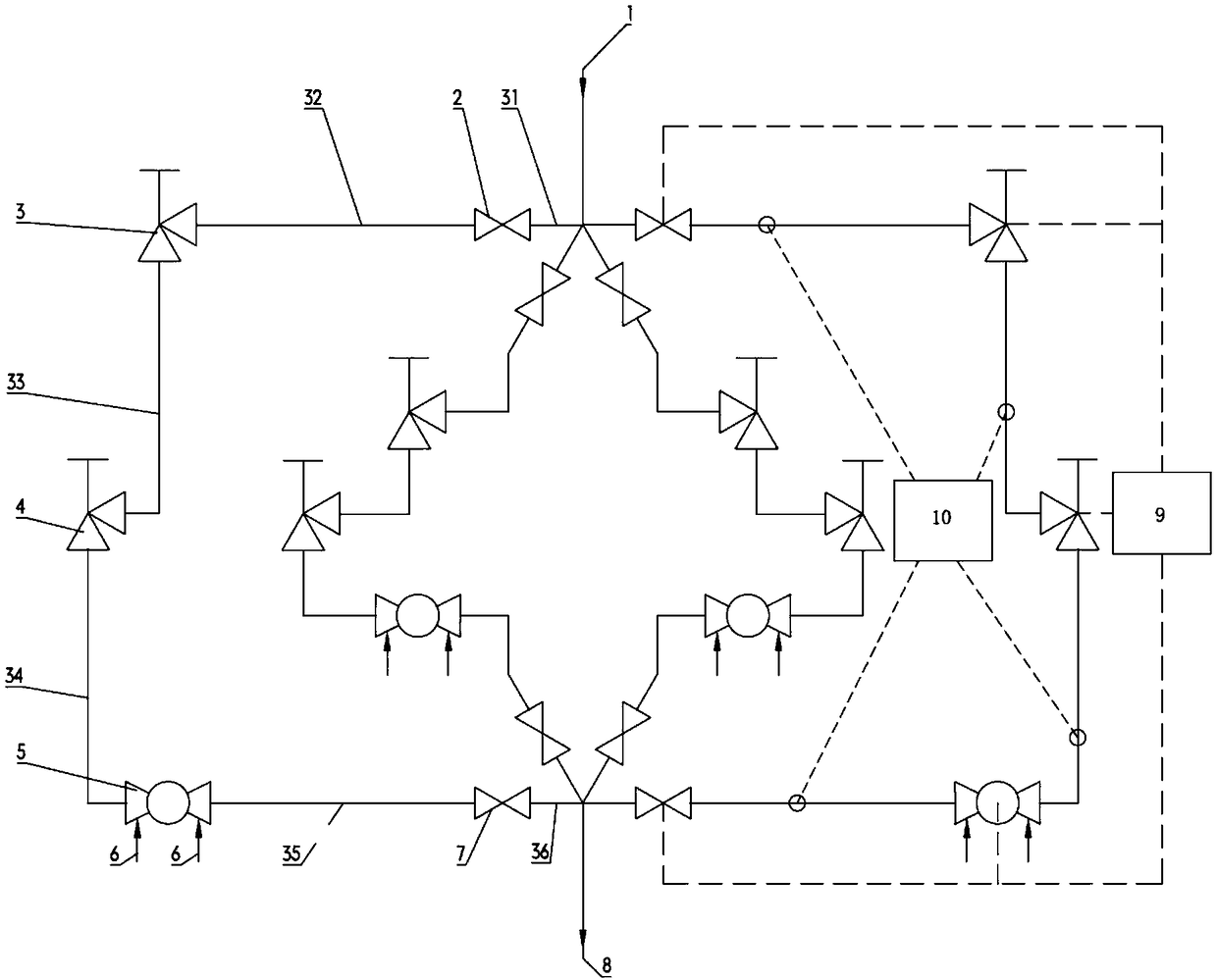

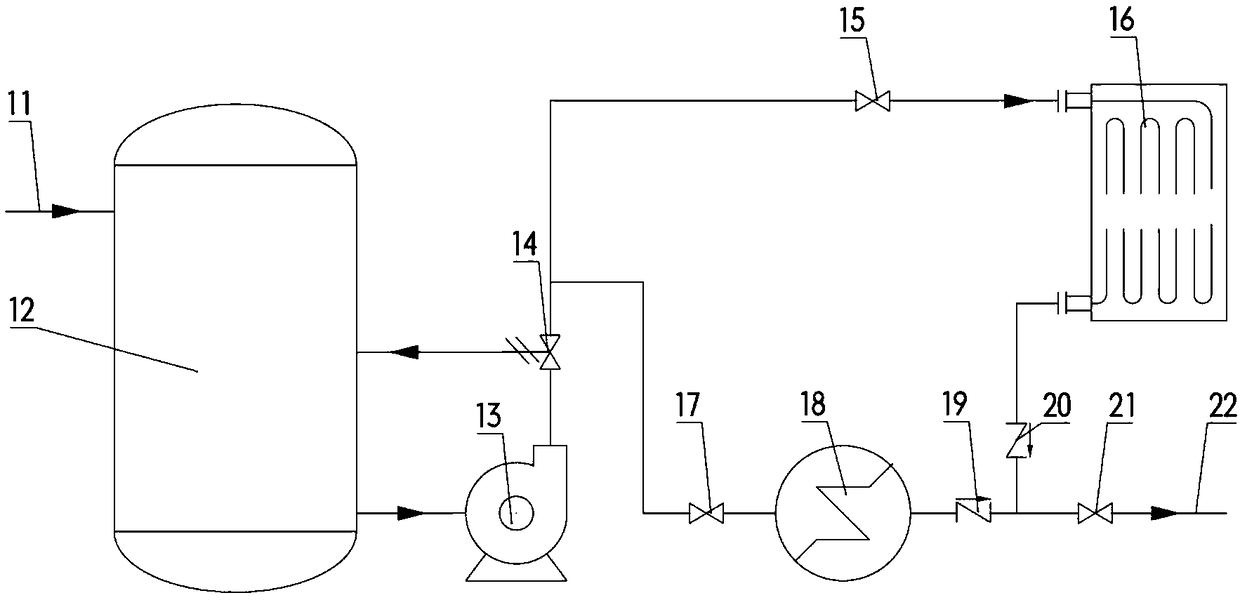

[0054] The invention relates to a skid-mounted decompression system, which is applied to coal chemical and petrochemical equipment. The decompression system includes a main process module, a mechanical control system, a thermal balance system and an intelligent control system. Such as figure 1 As shown, the process medium enters the main process module in the decompression system of the present invention. Under the instruction of the intelligent control system, the mechanical control system outputs torque, and each valve performs an action switch or adjusts the opening, thereby realizing the decompression of the process medium, and then Flow from pressure reducing system. At the same time, the needs of public works including oil, gas, steam, water, electricity, etc., enter the mechanical control system, intelligent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com