Upgraded ebullated bed reactor with increased production rate of converted products

A technology for ebullated bed reactors and conversion products, which is applied in the field of ebullated bed hydroprocessing methods and systems, and can solve the problems of asphaltene and carbon slag, which are difficult to handle, fouling, and limit downstream processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

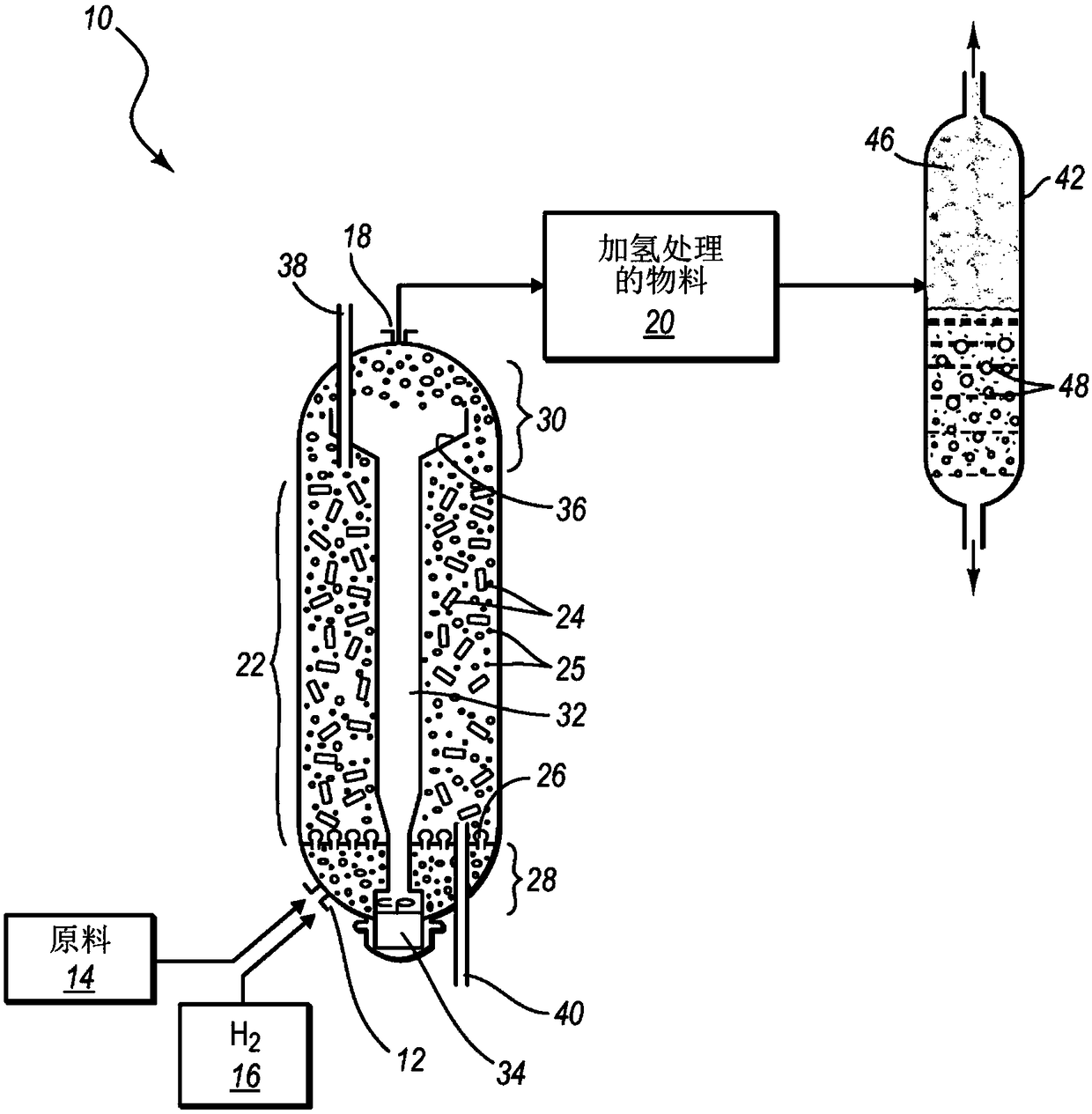

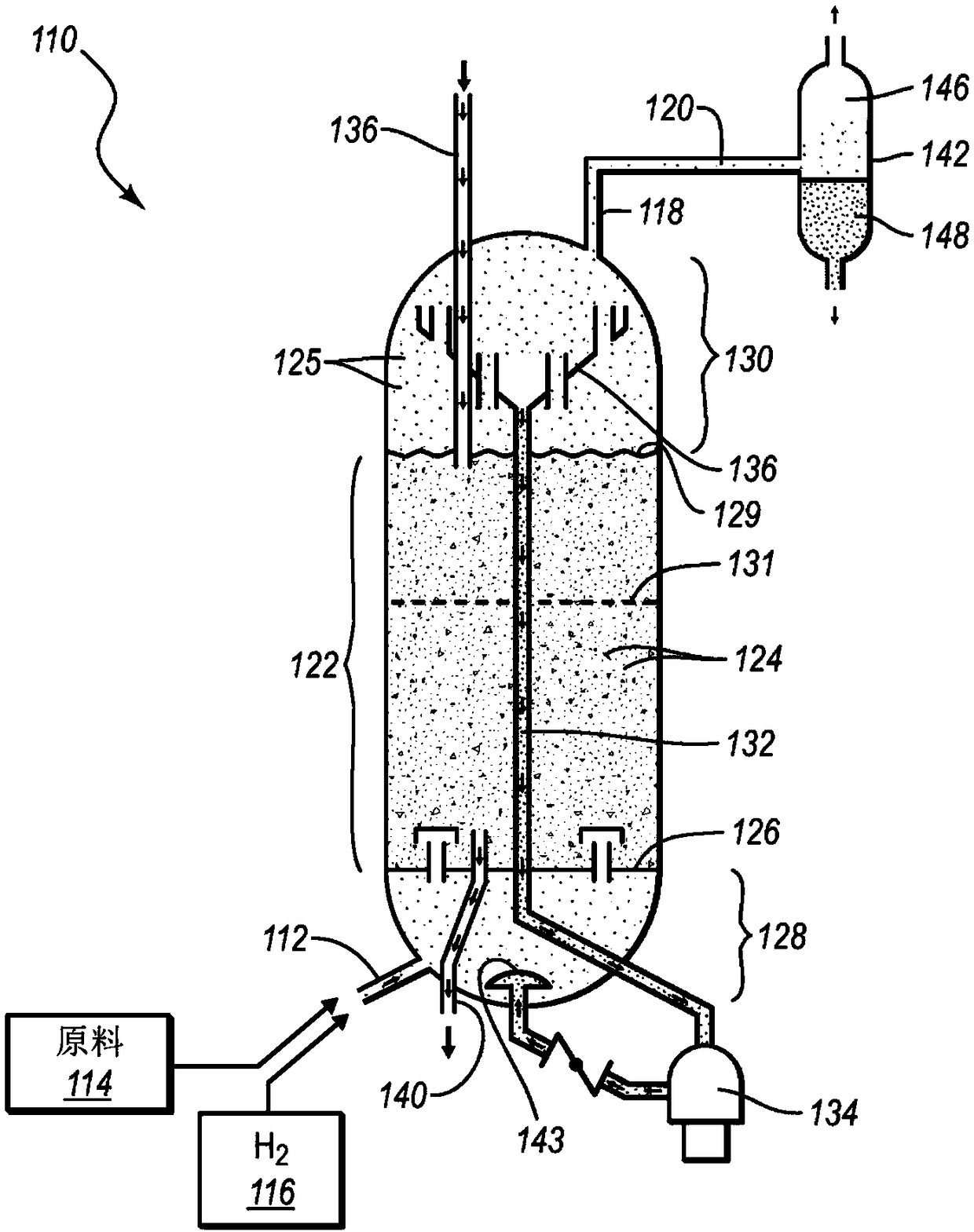

[0142] Examples 1-4 were carried out in the above-mentioned pilot plant and tested the ability of an upgraded ebullating bed reactor using a dual catalyst system to produce a relatively high conversion while maintaining or reducing deposit formation. Increased conversion includes higher resid conversion, C 7 Asphaltene conversion and micro carbon residue (MCR) conversion. The heavy oil feedstock used in this study was Ural vacuum residue (VR). As described above, the conditioned feedstock is prepared by mixing an amount of catalyst precursor mixture with an amount of heavy oil feedstock into a final conditioned feedstock containing the desired amount of dispersed catalyst. The exception to this is the test where no dispersed catalyst was used, in which case heavy vacuum gas oil was substituted for the catalyst precursor mixture in the same proportion. Feed the prepared raw materials into Figure 5 A pilot plant system that operates with specific parameters. Relevant proce...

Embodiment 1

[0147] Example 1 was a baseline test in which Ural VR was hydrotreated at a temperature of 789°F (421°C) and a resid conversion of 60.0%. In Example 2, the temperature was raised to 801°F (427°C) and the resid conversion (based on 1000°F+, %) increased to 67.7%. This resulted in a significant increase of 0.78% to 1.22% in product IP-375 deposits (separator substrate basis, wt%) and 0.67% to 0.98% in product IP-375 deposits (feed oil basis, wt%), C 7 Asphaltene conversion ranged from 40.6% to 43.0%, and MCR conversion ranged from 49.3% to 51.9%. This indicates that the heterogeneous catalysts used alone in Examples 1 and 2 cannot withstand an increase in temperature and conversion without a significant increase in deposit formation.

[0148] In Example 3 using a dual catalyst system including dispersed catalyst (providing 30 ppm Mo), the reactor temperature was increased to 801°F (427°C) and the resid conversion increased to 67.0%. The feed rate was slightly increased from 0....

Embodiment 3

[0149] The dual catalyst system of Example 3 is also significantly better than the heterogeneous catalyst used alone in Example 2, including the addition of C 7 Asphaltene conversion was further increased from 43.0% to 46.9%, and MCR conversion was further increased from 51.9% to 55.2%, while product IP-375 deposits (separator substrate basis, wt %) were significantly reduced from 1.22% to 0.76 %, and significantly reduced product IP-375 deposits (feed oil basis, weight %) from 0.98% to 0.61%.

[0150] In Example 4 using a two-catalyst system including dispersed catalyst (providing 50 ppm Mo), the reactor temperature was 801°F (427°C), the conversion was 65.9%, and the feed rate was 0.25 (LHSV, volumetric feed / volume reactor / hour). Compared with Example 1, the product IP-375 deposit (separator substrate basis, weight %) decreased significantly from 0.78% to 0.54%, and the product IP-375 deposit (feed oil basis, weight %) decreased from 0.67% Significantly down to 0.45%. In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com