Hydrocracking method for producing chemical materials

A technology for hydrocracking and chemical raw materials, which is applied in the fields of hydroprocessing process, petroleum industry, and hydrocarbon oil treatment, etc. It can solve the problem of reducing the aromatic potential and selectivity of heavy naphtha fractions, affecting the long-term operation of hydrocracking units, Increase the volume of the device and the amount of catalyst, etc., to achieve the effect of low nitrogen content, light distillation range, and difficult dehydrocoking reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

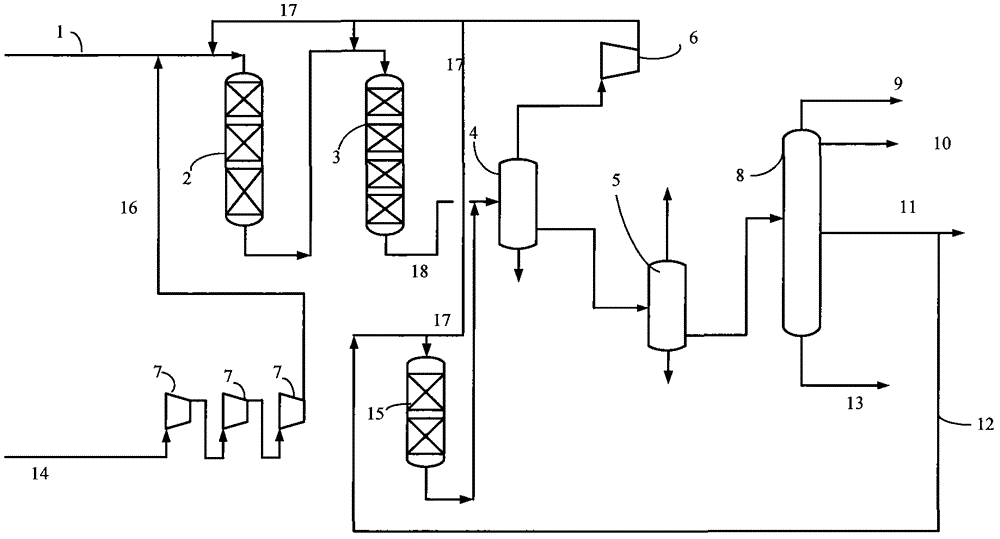

Method used

Image

Examples

Embodiment 1

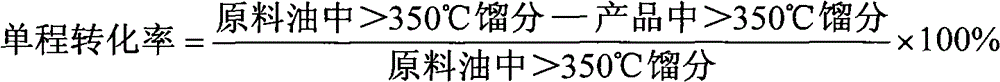

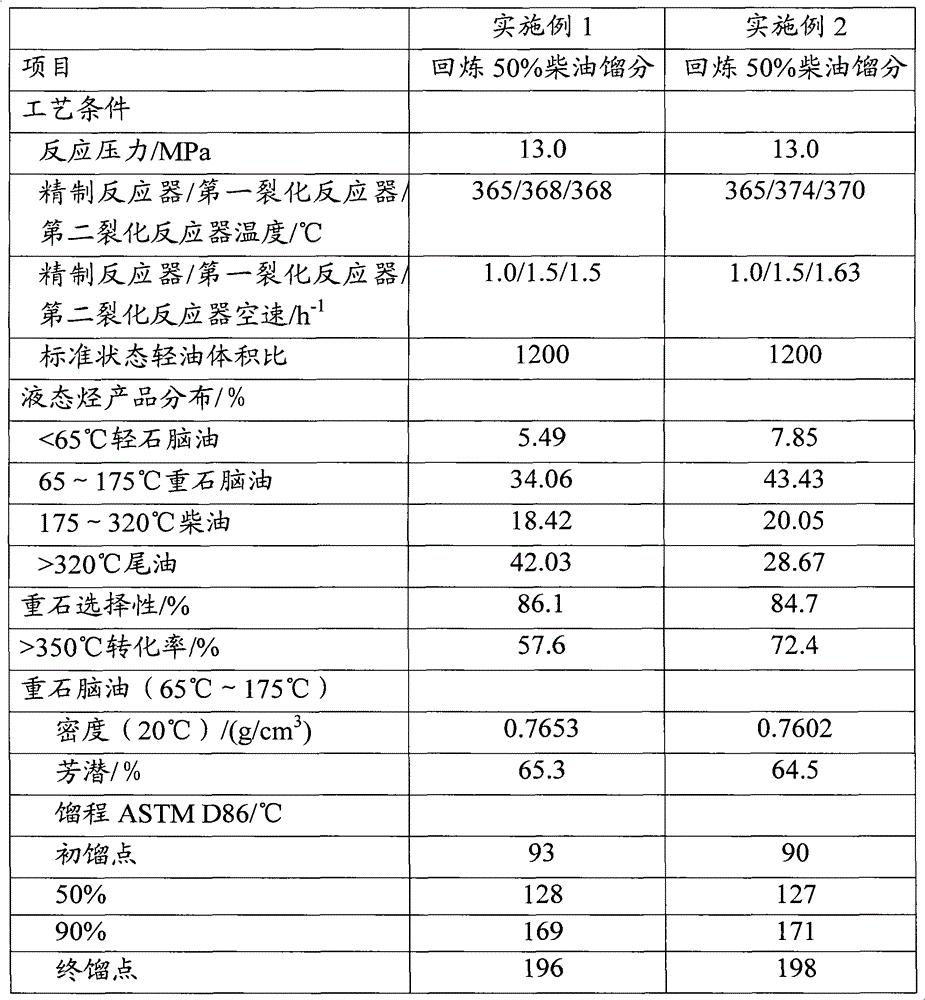

[0047] Using the method provided by the present invention, at a reaction pressure of 13.0MPa, a reaction temperature of a hydrotreating reactor of 365°C, and a space velocity of 1.0h -1 ; The reaction temperature of the first hydrocracking reactor is 368°C and the space velocity is 1.5h -1 ; The temperature of the second hydrocracking reactor is 368°C and the space velocity is 1.5h -1 Under the reaction conditions that the volume ratio of hydrogen to oil in a reverse inlet standard state is 1200, the hydrocracking test is carried out using raw material A (the catalyst used in the second hydrocracking reactor is a low metal loading hydrocracking catalyst II). During the test, 50% (accounting for the total volume of diesel fraction at 175-320°C) of the diesel fraction was recycled to the inlet of the second hydrocracking reactor. The test results are shown in Table 2.

[0048] As can be seen from Table 2, under the condition that the first hydrocracking reactor > 350 DEG C conv...

Embodiment 2

[0055]Adopt the method provided by the present invention, control the first hydrocracking reactor > 350 ℃ conversion rate 72%, under reaction pressure 13.0MPa, hydrorefining reactor reaction temperature 365 ℃, space velocity 1.0h -1 ; The reaction temperature of the first hydrocracking reactor is 374°C and the space velocity is 1.5h -1 ; Under the reaction condition that the volume ratio of hydrogen to oil in a reverse inlet standard state is 1200, the hydrocracking test is carried out by using raw material A (the second hydrocracking reactor is filled with hydrocracking catalyst II). 50% of the 175-320°C diesel fraction was recycled to the inlet of the second hydrocracking reactor. The reaction temperature of the second hydrocracking reactor was 370°C. The product distribution and product quality data of heavy naphtha are listed in Table 2. It can be seen from Table 2 that under the conditions of the first hydrocracking reactor>350°C conversion rate of about 72%, the yield of...

Embodiment 3

[0057] Adopt the method provided by the present invention, control first hydrocracking reactor > 350 ℃ conversion rate about 59%, at reaction pressure 13.0MPa, hydrotreating reactor reaction temperature 365 ℃, space velocity 1.0h -1 ; The reaction temperature of the first hydrocracking reactor is 369°C and the space velocity is 1.5h -1 ; Under the reaction condition that the volume ratio of hydrogen to oil in a reverse inlet standard state is 1200, the hydrocracking test is carried out by using raw material A (the second hydrocracking reactor is filled with hydrocracking catalyst II). 100% of the obtained 175-320°C diesel fraction is recycled to the inlet of the second hydrocracking reactor. The reaction temperature of the second hydrocracking reactor is 377°C. The product distribution and product quality data of heavy naphtha are listed in the table 3. It can be seen from Table 3 that under the conditions of the first hydrocracking reactor > 350 °C conversion rate of about 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com