Semiconductor processing system including vaporizer and method for using same

a technology of semiconductors and processing systems, applied in the direction of casings/cabinets/drawers, loudspeakers, coatings, etc., can solve the problems of deterioration of vaporizing efficiency, nozzle clogging and/or spray abnormalities, and increase in residues, so as to achieve stably the effect of semiconductor processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

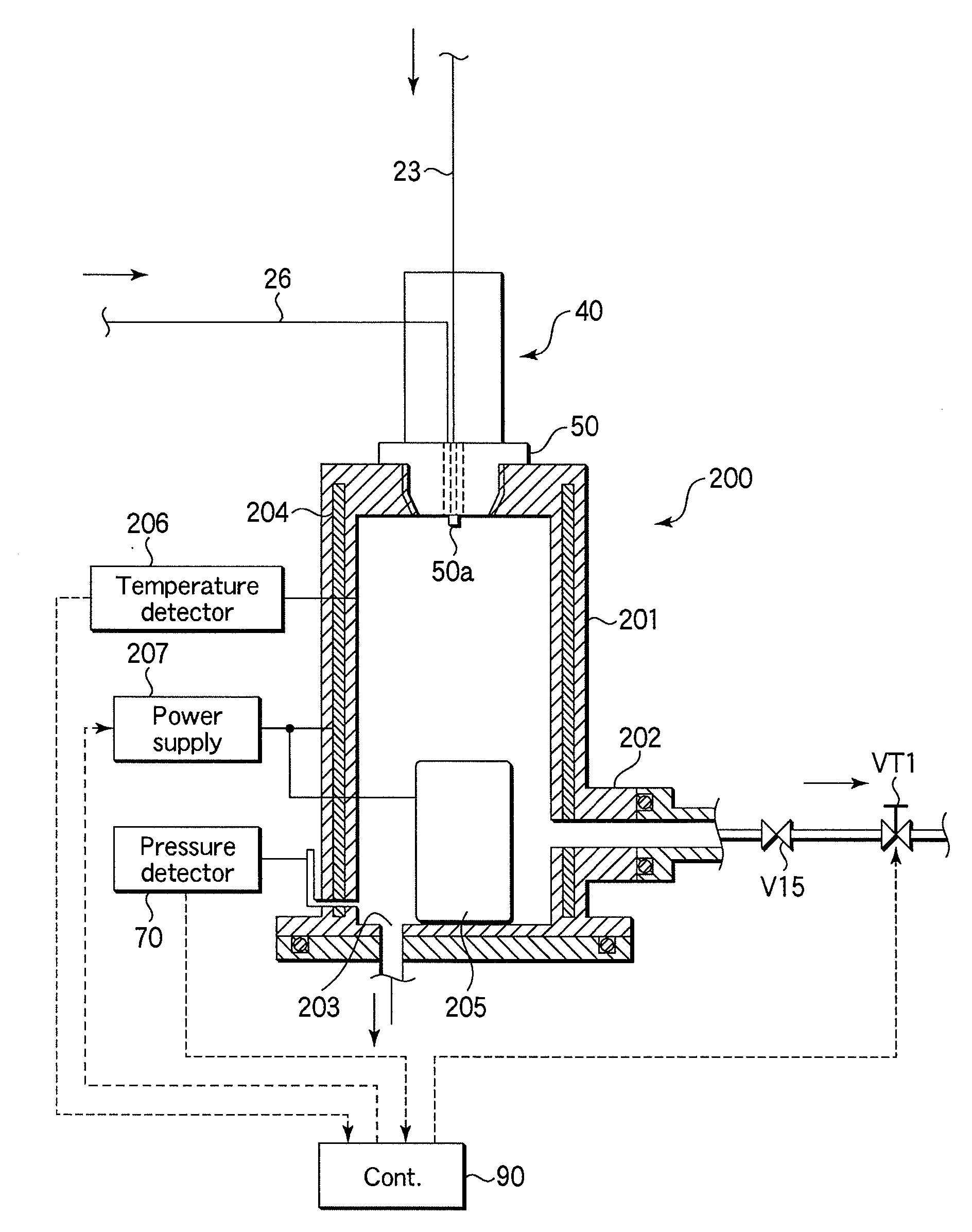

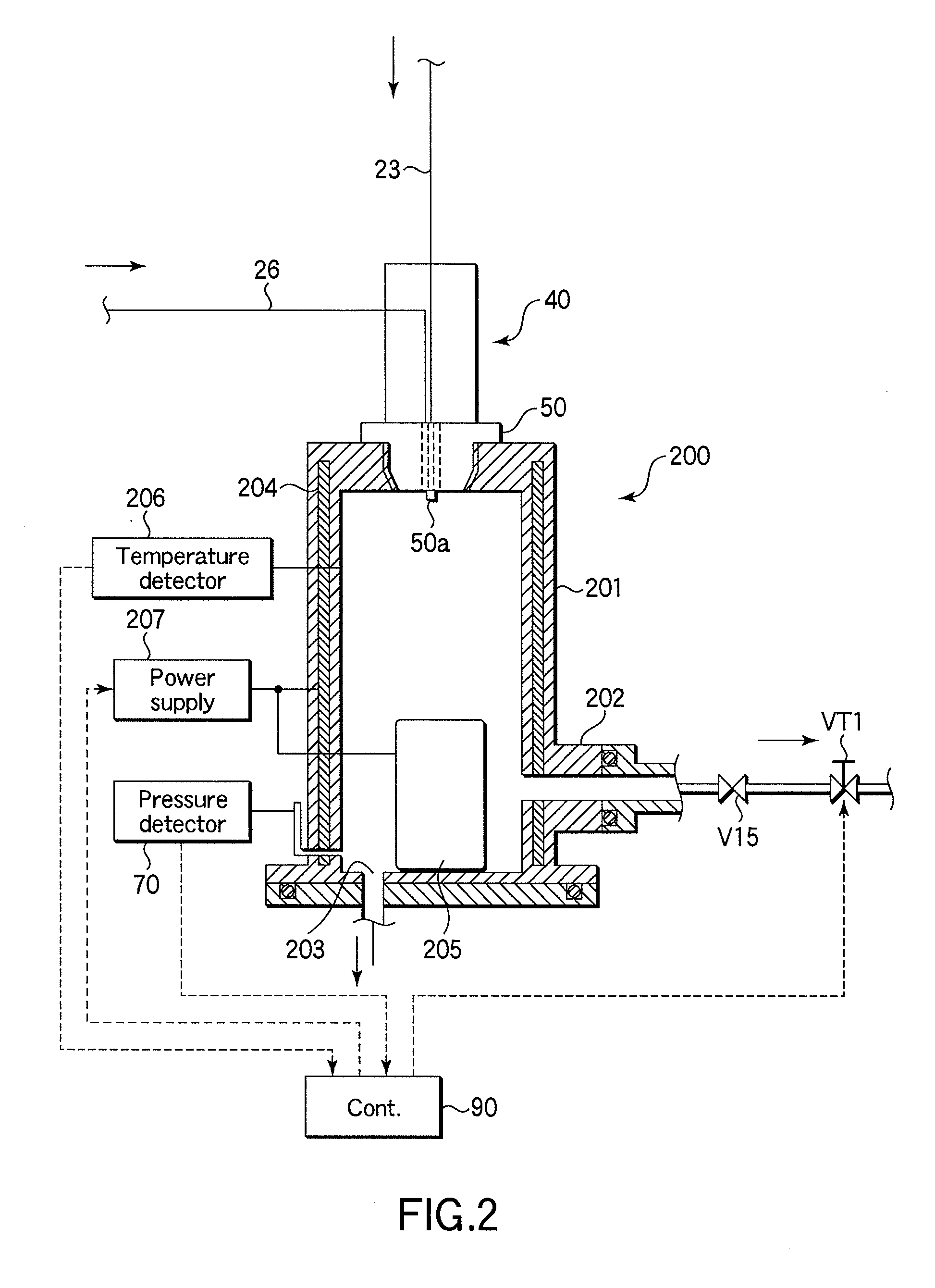

[0019]FIG. 1 is a structural view schematically showing a semiconductor processing system (film formation system) according to a first embodiment of the present invention. FIG. 2 is a sectional side view showing a vaporizer used in the gas supply apparatus of the system shown in FIG. 1. As shown in FIG. 1, the film formation system 1 according to this embodiment includes a film formation processing apparatus (semiconductor processing apparatus) 10 for performing a predetermined film formation process on target substrates, such as semiconductor wafers (which may be simply referred to as wafers), and a gas supply apparatus 20 for supplying a predetermined process gas into the film formation processing apparatus 10.

[0020]For example, the film formation section 10 comprises a low-pressure CVD apparatus of the batch type having a vertical reaction tube 11 used as a reaction chamber (process chamber). A wafer boat 12 that can support a number of wafers W is loaded and unloaded into and fr...

second embodiment

[0047]FIG. 4 is a structural view schematically showing a semiconductor processing system according to a second embodiment of the present invention. The film formation system 101 according to the second embodiment is arranged to control the pressure inside the vaporizing chamber by adjusting the flow rate of the solvent supplied to the liquid material supply line 23 by use of the flow rate regulator (serving as pressure adjusting means) M3 disposed on the solvent supply line 22c. Accordingly, this arrangement is an alternative to the arrangement of the first embodiment which controls the pressure by use of the regulator valve VT1 disposed on the process gas supply line 30. When the film formation system 101 is normally performs a process, it operates in the same way as the film formation system 1 according to the first embodiment.

[0048]Specifically, when a film formation process is started, the opening degree of the flow rate regulator M3 is set at zero so as not to supply the solve...

third embodiment

[0050]FIG. 5 is a structural view schematically showing a semiconductor processing system according to a third embodiment of the present invention. The film formation system 1001 according to the third embodiment is arranged to control the pressure inside the vaporizing chamber by adjusting the flow rate of the carrier gas supplied into the vaporizing chamber by use of the flow rate regulator (serving as pressure adjusting means) M4 disposed on the carrier gas supply line 26. Accordingly, this arrangement is an alternative to the arrangement of the first embodiment which controls the pressure by use of the regulator valve VT1 disposed on the process gas supply line 30. When the film formation system 1001 is normally performs a process, it operates in the same way as the film formation system 1 according to the first embodiment.

[0051]Specifically, when a film formation process is started, the opening degree of the flow rate regulator M4 is set at 50%, so as to supply the carrier gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| boiling temperature | aaaaa | aaaaa |

| hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com