Lubricating method for sectional material rolling

A profile and lubricating fluid technology, applied in the direction of metal rolling, metal rolling, rolls, etc., can solve the problems of difficult control of product size specifications, many factors affecting the lubrication effect, complex deformation, etc., to improve product surface quality and reduce rolls Consumption, improve the effect of rolling rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

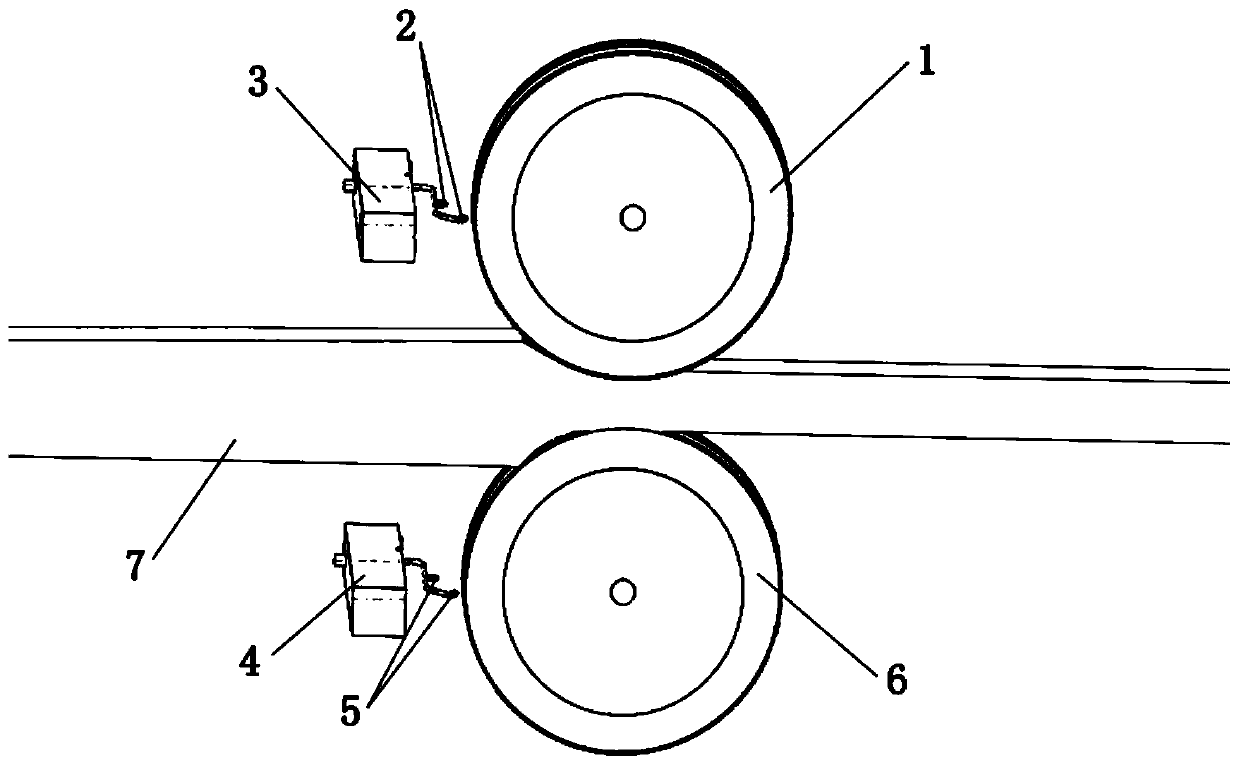

[0015] See figure 1 , the upper and lower nozzles 2 and 5 are respectively fixed at the beams 3 and 4 of the upper and lower rolls of the UF rolling mill, and two fan-shaped water nozzles are respectively arranged on the upper and lower nozzles 2 and 5, and the fan-shaped water nozzles connect the upper and lower rolls 1 and 6 Full coverage, in order to achieve the purpose of full hole spray.

[0016] The on-site net ring water pipeline is used for water supply, and the flow control valve controls the water flow; the raw liquid adopts the pump motor frequency conversion speed regulation method, and the raw liquid flow is controlled by controlling the motor speed.

[0017] The raw liquid and water are mixed in a mixer to form a lubricating liquid of a certain concentration, and the lubricating liquid is sprayed onto the surfaces of the upper and lower rolls 1 and 6 through fan-shaped water nozzles to achieve the purpose of lubricating the profile 7.

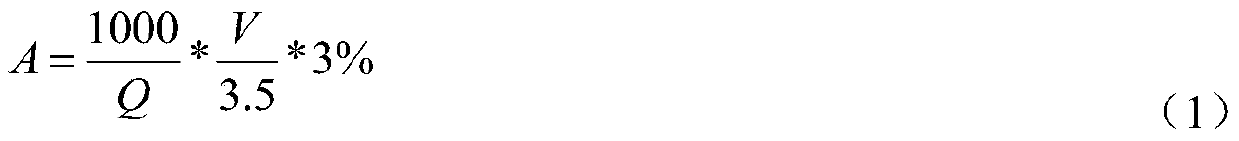

[0018] Set the formula ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com