Wear-resistant rotary feeder with labyrinth seal structures on rotor end surface

A rotary feeder, labyrinth sealing technology, applied in conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of poor rotor end face sealing, prone to reverse wind, short service life, etc., to achieve good sealing, The effect of reducing material shearing and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

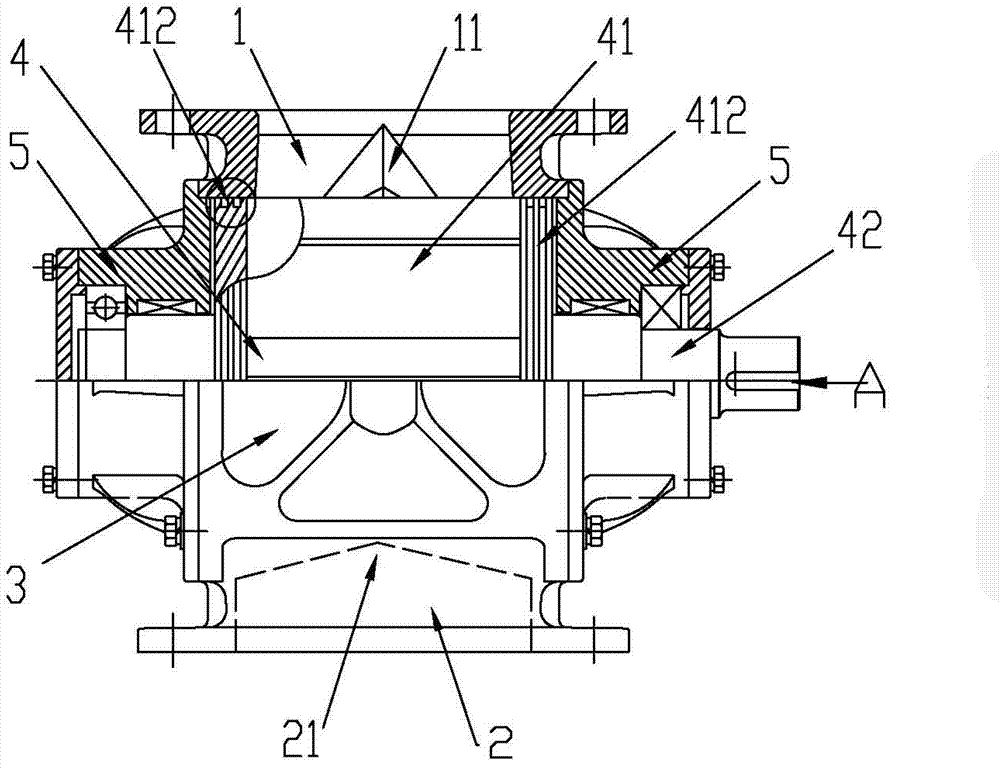

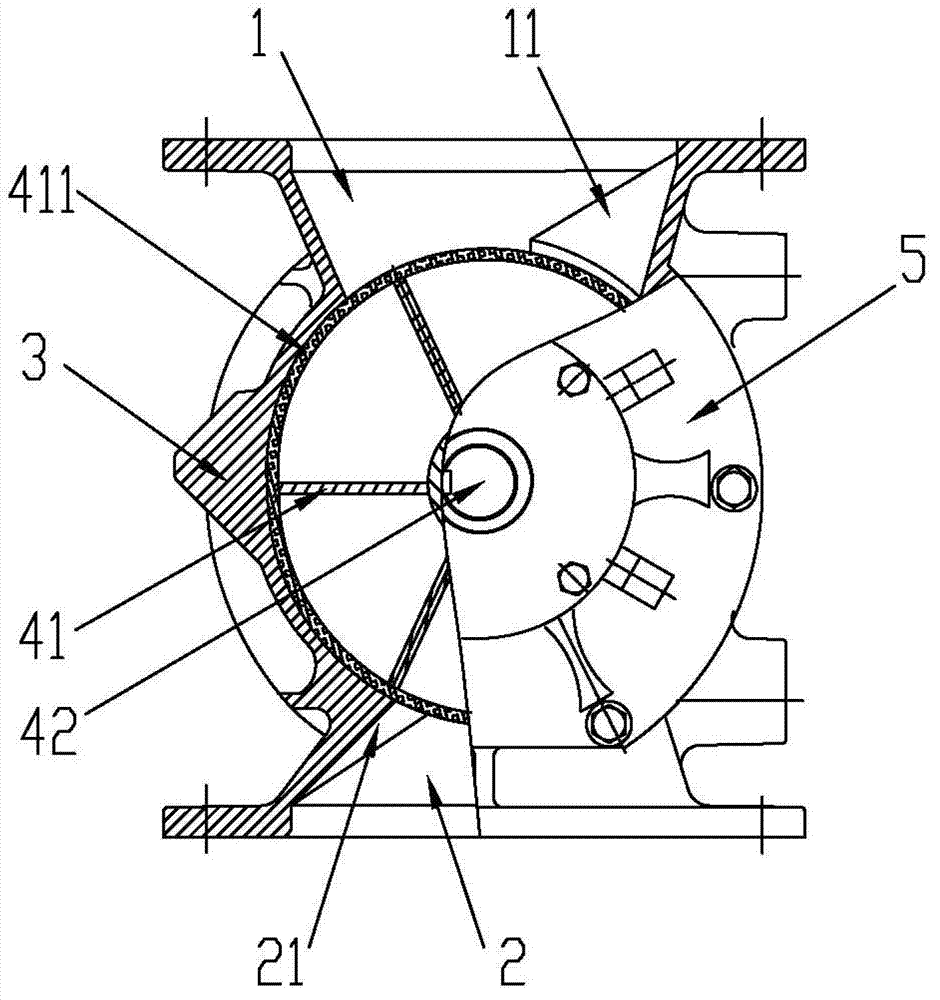

[0018] Such as Figure 1-4 As shown, the present invention is a wear-resistant rotary feeder with a labyrinth seal structure on the end face of the rotor, which includes a feed port 1, a discharge port 2, a housing 3, and a rotor 4 laterally installed inside the housing. The two ends of the body 3 are provided with end caps 5, and the end caps 5 are fixed on both sides of the housing 3 by bolts. The inner wall surface of the housing 3 is coated with a wear-resistant layer 31, and the inner wall surface of the housing is durable. The grinding layer is made of high-hard wear-resistant material, which can improve the wear resistance of the inner wall of the shell, and avoid the frequent contact between the inner wall and the material during the material transmission process, and the serious wear of the inner wall of the shell.

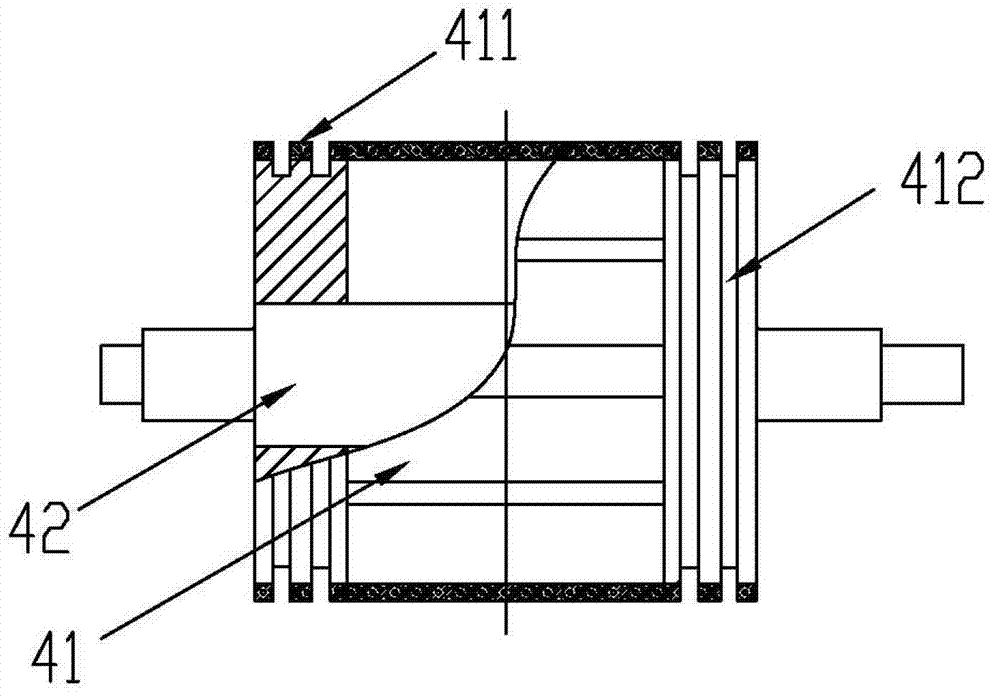

[0019] The rotor 4 includes an impeller 41 and a rotating shaft 42, the rotating shaft 42 is arranged at the center of the impeller 41, and one end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com