Preparation method of animal-plant mixed fat cream powder

A technology of mixing fat and cream powder, which is applied in the production/processing of edible oil/fat components, edible oil/fat, etc., can solve the problems of occupying refrigeration storage equipment, poor cooking performance, and increased cold chain storage costs, etc. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present invention proposes the optimal ratio combination of ingredients. After experimental design and repeated verification, the results prove that the optimal ratio combination of cream, fully hydrogenated vegetable oil, emulsifier and stabilizer proposed by the present invention, through appropriate processing technology, finally obtained After rehydration, cream powder has the best whipping effect. The combination of ingredients is as follows:

[0027] Refined vegetable oil 10-35%; cream 5-20%; compound emulsifier: 1.2-10.0%; glucose syrup: 30-55%; compound thickener: 0.01-0.6%. The fluctuation range of raw materials corresponds to different formulas and cream powder varieties.

Embodiment 2

[0029] A method for preparing animal and plant mixed fat cream powder, comprising the following steps:

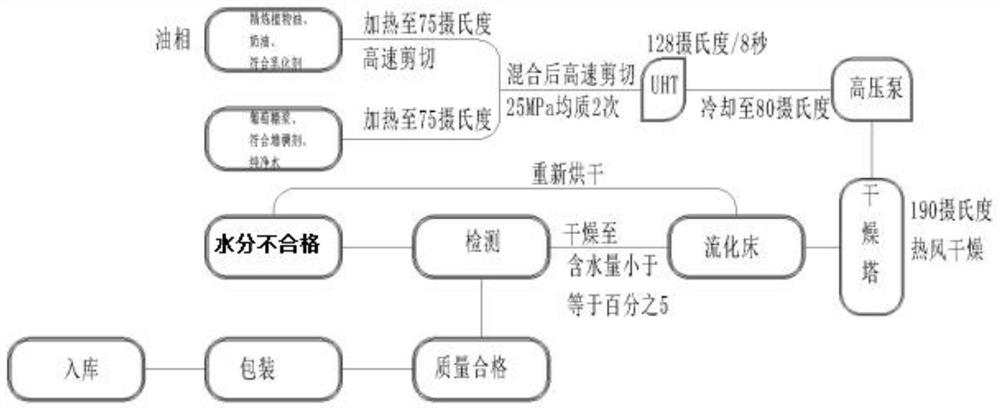

[0030] Please refer to the process flow chart: heat the refined vegetable oil, butter and compound emulsifier of the oil phase raw materials, and perform high-speed shearing to obtain the main material for use; add glucose syrup and compound thickener to pure water and heat to obtain auxiliary materials for use; After the main material and auxiliary materials are mixed, they are subjected to high-speed shearing and homogenized twice at 25MPa; then the mixture is sterilized at a high temperature in a UHT sterilizer, and then cooled to 80 degrees Celsius; then it is transported to a drying tower by a high-pressure pump for drying Add the dried material to the fluidized bed for fluidization and drying; pack the material that meets the quality standard into the warehouse; re-dry the material that does not meet the moisture requirement, and return to step S6 for reprocessing.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com