Catalyst carrier for olefin polymerization, catalyst for olefin polymerization and preparation methods and application of catalyst carrier and catalyst

A catalyst carrier and olefin polymerization technology, which is applied in the field of olefin polymerization, can solve the problems of poor carrier molding effect, difficult control of experimental conditions, unstable preparation results, etc., and achieve good product molding effect, reduce production costs, and increase stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] In a first aspect, the present invention provides a method for preparing a catalyst carrier for olefin polymerization, the method comprising:

[0032] 1) the magnesium halide shown in the general formula MgXY and the general formula R 1 The alcohol compound represented by OH and the optional inert liquid medium are contacted to form an emulsion;

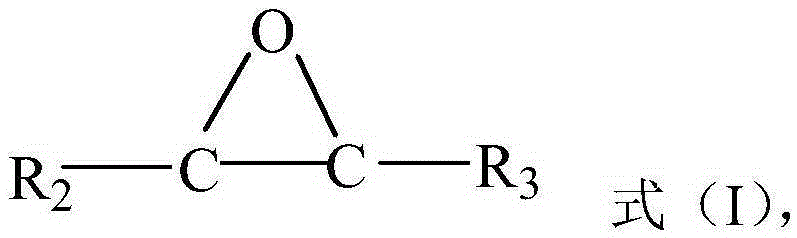

[0033] 2) The emulsion obtained in step 1) is contacted with the oxirane compound represented by the general formula (I) at a flow ratio of 1.5-6:1;

[0034] Wherein, in the general formula MgXY, X is chlorine or bromine, and Y is selected from chlorine, bromine, C 1 -C 14 Alkyl, C 1 -C 14 Alkoxyl, C 6 -C 14 Aryl or C 6 -C 14 A group consisting of aryloxy groups;

[0035] In general formula R 1 OH, R 1 for C 1 -C 12 Alkyl, C 3 -C 10 Cycloalkyl or C 6 -C 10 the aryl group;

[0036] The oxirane compound has a structure shown in formula (I):

[0037]

[0038] In formula (I), R 2 and R 3 each independently ...

preparation example 1

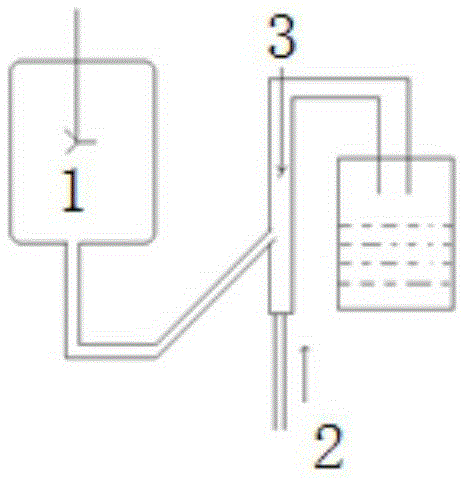

[0097] In a 0.6L reactor, add 0.08mol magnesium chloride and 1.7mol ethanol, and raise the temperature to 90°C with stirring. After 1 hour of constant temperature reaction, high-speed stirring (1800rpm) 0.5h, pressurized input pipeline, make the flow of described emulsion in described pipeline be 15mL / min, input flow from the inlet of another pipeline simultaneously is 5mL / min, temperature It is 90°C epichlorohydrin (the angle between the two pipes is 12°), and the two are mixed in the tubular area into the reaction kettle equipped with hexane. It was washed 5 times and dried in vacuum to obtain catalyst carrier Z1 for olefin polymerization.

[0098] The average particle diameter (D50) of the catalyst carrier Z1 for olefin polymerization is 70 microns, and the particle size distribution ((D90-D10) / D50) is 0.8. The particle shape of the catalyst carrier Z1 for olefin polymerization is relatively regular, the surface is smooth, basically spherical, the particle size distributio...

preparation example 2

[0103] In a 0.6L reactor, add 0.08mol magnesium chloride and 1.2mol ethanol, and raise the temperature to 65°C under stirring. After constant temperature reaction for 1 hour, stir at high speed (1800rpm) for 0.5h and then raise the temperature to 85°C, pressurize the input pipeline, so that the flow rate of the emulsion in the pipeline is 20mL / min, and at the same time, the input flow rate from the inlet of another pipeline is 5mL / min, epichlorohydrin at a temperature of 85°C (the angle between the two pipes is 12°), the two are mixed in the tubular area into the reaction kettle filled with hexane, after the delivery is completed, press filter, and press The filtered product was washed 5 times with hexane and dried in vacuum to obtain the catalyst carrier Z2 for olefin polymerization.

[0104] The average particle diameter (D50) of the catalyst carrier Z2 for olefin polymerization is 72 microns, and the particle size distribution ((D90-D10) / D50) is 0.8. The particle shape of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle diameter | aaaaa | aaaaa |

| Average particle diameter | aaaaa | aaaaa |

| Average particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com