Guide rail type piston rack for electro-hydraulic switch machine

A switch machine, guide rail technology, applied in mechanical equipment, components with teeth, portable lifting devices, etc., can solve the problems of friction surface wear, affecting the service life of switch oil cylinders, etc. The effect of reducing the driving power and reducing the starting pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

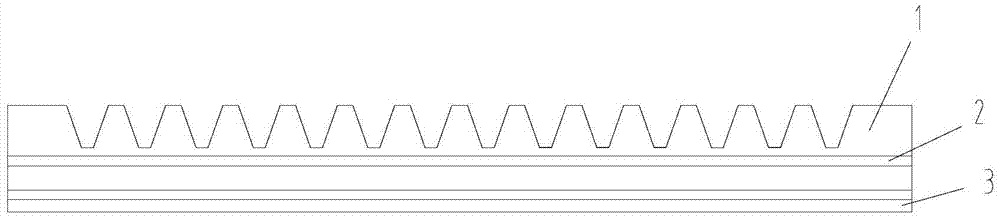

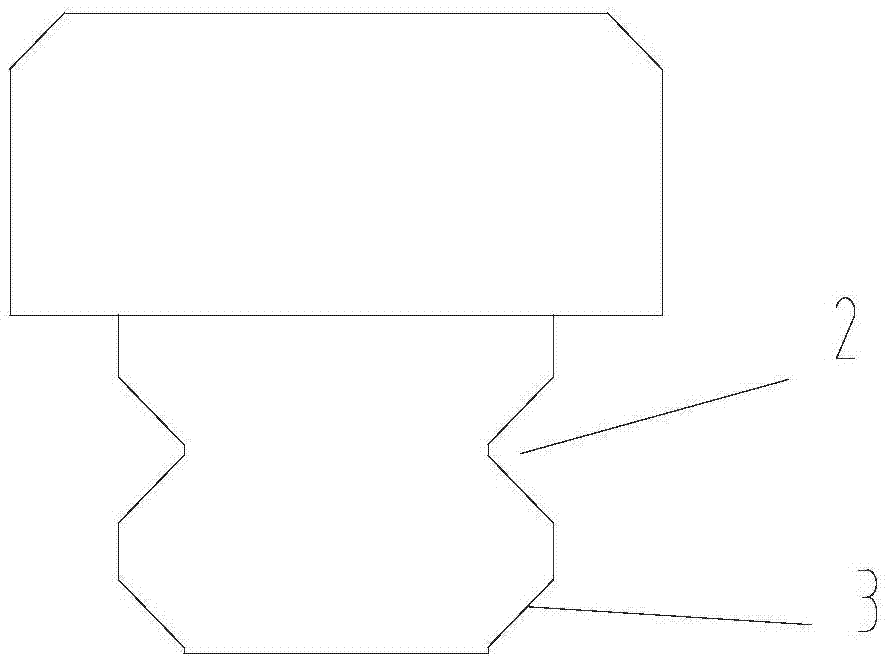

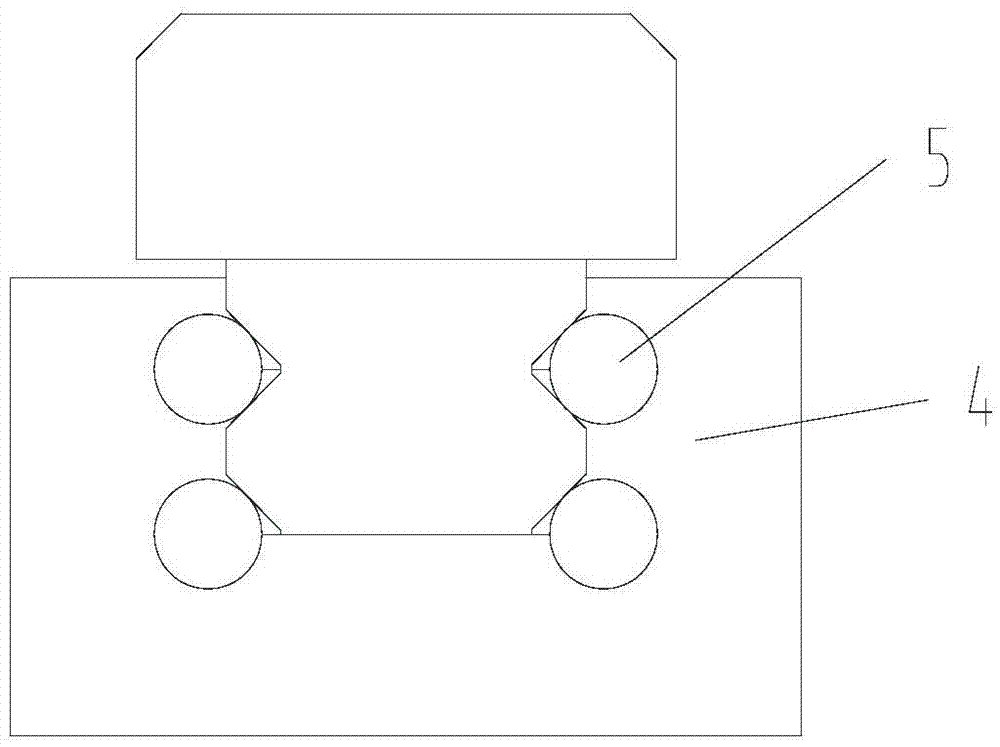

[0012] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as Figure 1 to Figure 3 As shown, a guide rail type piston rack for an electro-hydraulic switch machine includes a rack body 1, the two sides of the rack body are respectively provided with V-shaped grooves 2 along the length direction of the rack, and the rack The lower part of the body is provided with an inclined surface 3, the rack body is slidingly fitted with the inner wall 4 of the oil cylinder seat, grooves are respectively provided on the inner wall of the oil cylinder seat corresponding to the V-shaped groove and the inclined surface, and the A steel ball 5 is arranged in the groove. The V-groove is filled with grease. The guide rail type piston rack used in the oil cylinder of the present invention changes the previous sliding friction into rolling friction. The friction force is also re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com