Oil injector capable of adjusting oil outlet volume

An oil injector and oil output technology, which is used in quantitative devices, engine lubrication, engine components, etc., can solve the problems of limited adaptable temperature range, inaccurate quantitative, unstable performance, etc., and achieve a wide applicable temperature range and quantitative Precise oil injection and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

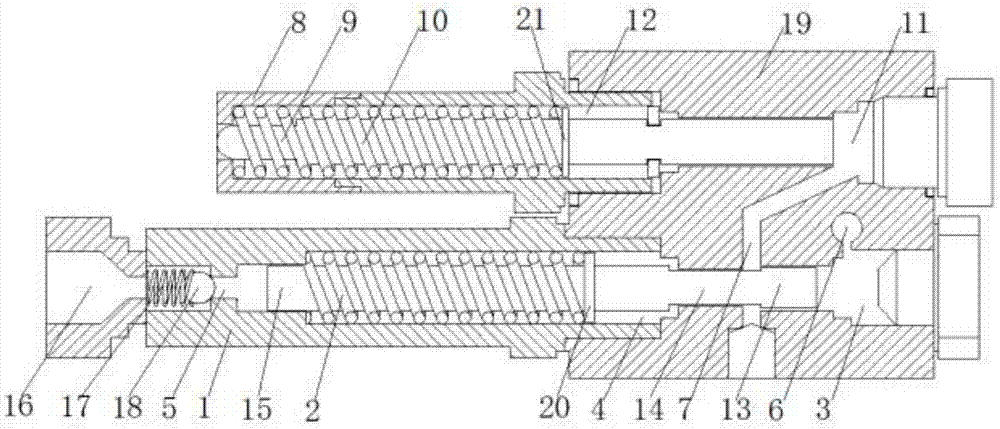

[0026] combine figure 1 As shown, the invention discloses an oil injector with adjustable oil output, which includes an oil injection unit and an oil storage unit. The oil injection unit includes a main measuring cylinder 1, a main measuring plunger and a first spring 2. The main measuring cylinder 1 includes a first chamber 3, a second chamber 4 and a third chamber which are sequentially communicated along its axis. The chamber 5, the main measuring plunger is arranged in the main measuring cylinder barrel 1 . The main volume plunger includes a first segment shaft 13, a second segment shaft 14 and a third segment shaft 15 which are sequentially distributed along the dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com