Efficient energy-saving sewage treatment device

A sewage treatment device, high-efficiency and energy-saving technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Maintenance and other problems, to avoid the loss of cold source, save investment and space occupation, and facilitate maintenance and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

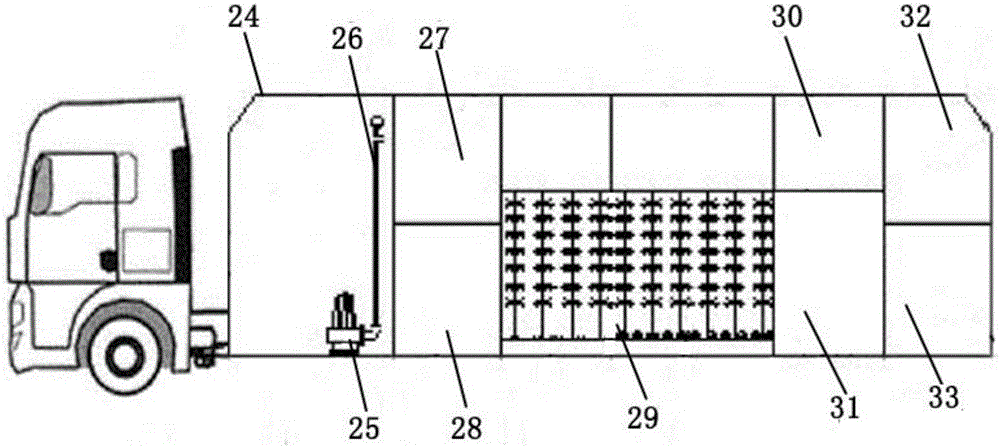

[0022] Such as figure 1 A high-efficiency and energy-saving sewage treatment device shown is transformed from a car as a whole, including a compartment 24, sewage treatment equipment installed in the compartment 24, and an engine energy recovery system. The compartment 24 includes a plurality of reaction chambers. The sewage treatment equipment includes a pump 25, a solid-liquid separation tank 27, a grease trap 28, a biochemical tank 29, a filter tank 30, a sedimentation tank 31, a clear water return tank 32 and a disinfection tank 33 connected successively by a pipeline 26, and the sewage is in the above order Process them sequentially.

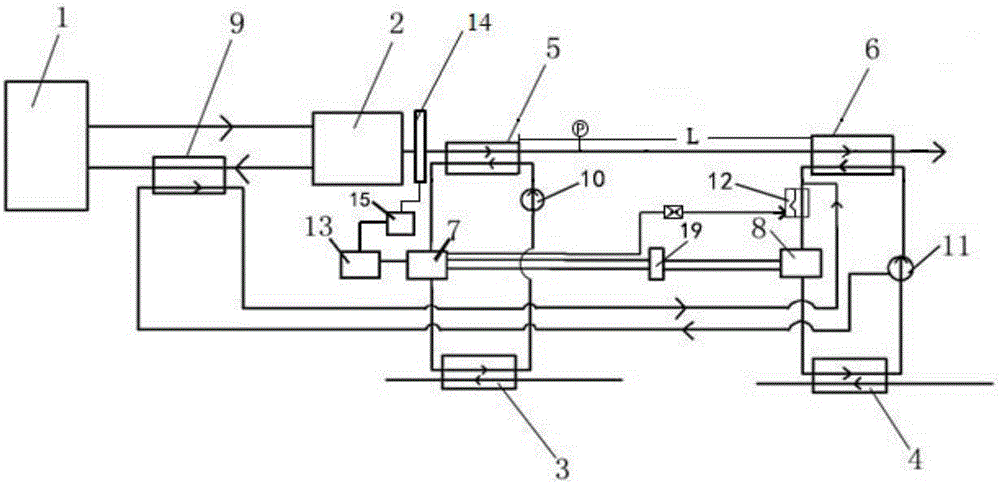

[0023] Such as figure 2 As shown, the engine energy recovery system is used to recover the energy of automobile engine exhaust, which includes a radiator 1, an engine 2, a return water evaporator 9, a high-temperature heat exchange circuit, a low-temperature heat exchange circuit, a battery pack 13, an inverter and a frequency conversion ...

Embodiment 2

[0033] Such as figure 1 A high-efficiency and energy-saving sewage treatment device shown is transformed from a car as a whole, including a compartment 24, sewage treatment equipment installed in the compartment 24, and an engine energy recovery system. The compartment 24 includes a plurality of reaction chambers. The sewage treatment equipment includes a pump 25, a solid-liquid separation tank 27, a grease trap 28, a biochemical tank 29, a filter tank 30, a sedimentation tank 31, a clear water return tank 32 and a disinfection tank 33 connected successively by a pipeline 26, and the sewage is in the above order Process them sequentially.

[0034] Such as figure 2 As shown, the engine energy recovery system is used to recover the energy of automobile engine exhaust, which includes a radiator 1, an engine 2, a return water evaporator 9, a high-temperature heat exchange circuit, a low-temperature heat exchange circuit, a battery pack 13, an inverter and a frequency conversion ...

Embodiment 3

[0044] Such as figure 1 A high-efficiency and energy-saving sewage treatment device shown is transformed from a car as a whole, including a compartment 24, sewage treatment equipment installed in the compartment 24, and an engine energy recovery system. The compartment 24 includes a plurality of reaction chambers. The sewage treatment equipment includes a pump 25, a solid-liquid separation tank 27, a grease trap 28, a biochemical tank 29, a filter tank 30, a sedimentation tank 31, a clear water return tank 32 and a disinfection tank 33 connected successively by a pipeline 26, and the sewage is in the above order Process them sequentially.

[0045] Such as figure 2 As shown, the engine energy recovery system is used to recover the energy of automobile engine exhaust, which includes a radiator 1, an engine 2, a return water evaporator 9, a high-temperature heat exchange circuit, a low-temperature heat exchange circuit, a battery pack 13, an inverter and a frequency conversion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com