Expansion pipe necking method

An expansion tube and necking technology, applied in the field of shrinking expansion tube, can solve the problems of affecting the sealing effect of the connection between the workpiece and the external connector, insufficient product structural strength, and distortion of the workpiece by extrusion force, so as to achieve convenient connection strength and sealing effect. , convenient for industrial application, uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

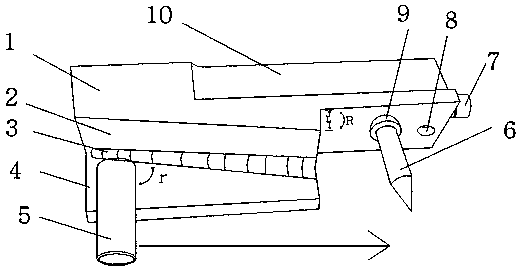

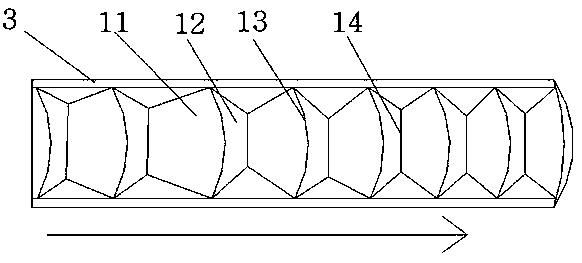

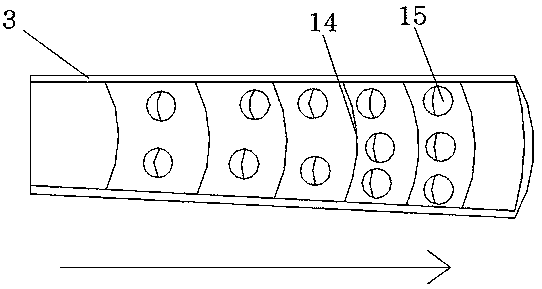

[0029] Such as Figure 1-4 Shown: a shrinking method of the expansion tube 5, the wall thickness of the expansion tube 5 is 5mm, and the inner diameter is 20mm, the expansion tube 5 is formed by impacting the workpiece with a mold, and the workpiece is heated to 500-1800°C. The workpiece is softened, and the strength of each impact is less than 100 kgf.

[0030] Preferably, the impact force is 5-50 kg force; more preferably, the impact force is 30 kg force. When the impact force is too small, the shrinking effect on the expansion tube 5 is poor, and the processing time is long and the efficiency is low. When the impact force is greater than 100 kg When the force is applied, the shrinkage force is too large, which is not conducive to uniform thickening. At the same time, the impact force can be adjusted according to the material of the expansion tube 5 and the degree of softening; while the impact is made, the expansion tube 5 moves slowly to the tail of the mold for relative m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com