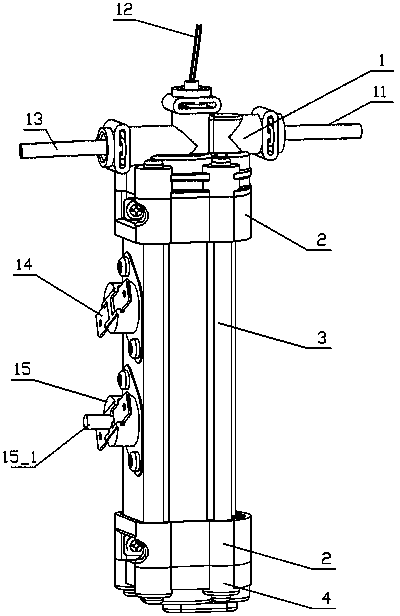

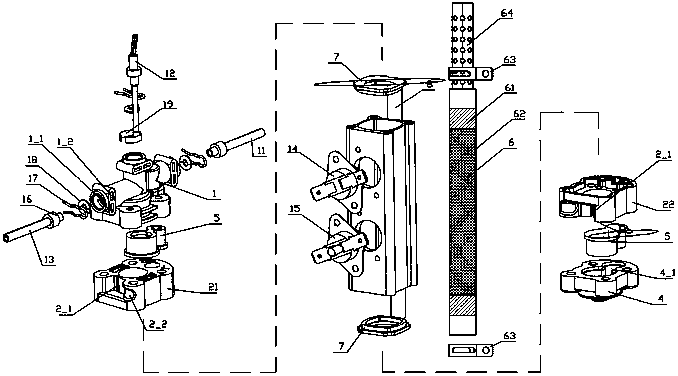

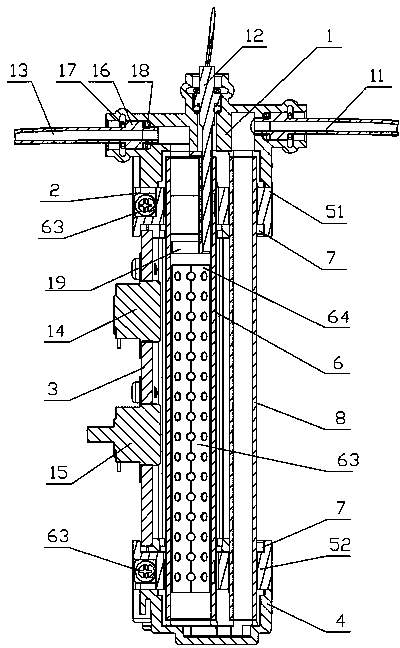

Pressure type liquid quick heater

A pressure-type, quick-heater technology, applied in beverage preparation devices, household appliances, applications, etc., can solve problems such as insufficient dissolution of coffee powder, large temperature drift of temperature-sensing probes, and accelerated aging of internal components, etc., to achieve rapid disassembly Install, solve the effect of hot temperature rise and increase power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0057] The installation method of the temperature-sensing probe, the automatic reset thermostat, and the manual reset thermostat of Embodiment 2 and Embodiment 3 is the same as that of Embodiment 1, and the structure of the heating pipe is the same as that of Embodiment 1, and silica gel is installed at each connection port. sealing ring.

[0058] The invention can be used as a heater in pressure coffee machines, water boilers, humidifiers and other products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com