An active top tooling

A tooling and cutting-edge technology, applied in the direction of fine working devices, working accessories, manufacturing tools, etc., can solve the problems of poor carrying capacity of ordinary heavy-duty tops, short service cycles, high rework rate, etc., to achieve superior machining accuracy and carrying capacity, The effect of preventing water and garbage from entering the interior and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

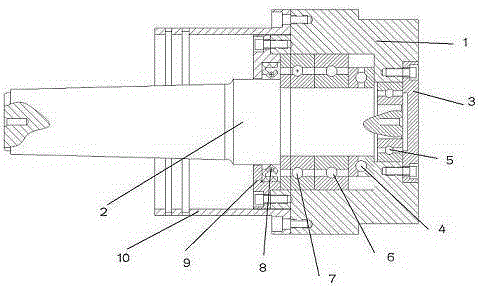

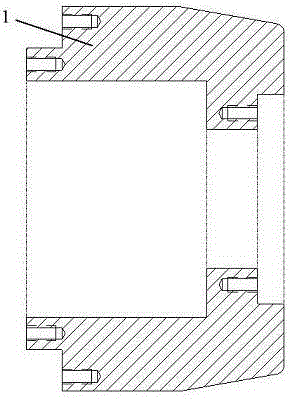

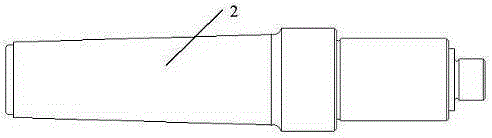

[0020] Such as Figure 1-6 The movable top tooling shown includes: top sleeve 1, top shaft core 2, end cover 3, thrust bearing 4, No. 1 deep groove ball bearing 5, No. 2 deep groove ball bearing 6, No. 3 deep groove ball bearing 7 , Skeleton oil seal 8, bearing end cover 9, waterproof sleeve 10;

[0021] The model of the top shaft core 2 is Mohs No. 5#; the top sleeve 1 and the top shaft core 2 are made of 40Cr standard steel.

[0022] Tail end cover 3, bearing end cover 9, waterproof cover 10 are the steel products of No. 45 standards.

[0023] Such as Figure 6 As shown, the tail end cap 3 is a hollow circular pie shape, with a diameter of 71mm and a thickness of 9mm;

[0024] Such as Figure 5 As shown, the bearing end cover 9 has a thickness of 16 mm and a diameter of 102 mm, and its hollow ring includes two rings with diameters of 51 mm and 70 mm respectively.

[0025] Such as Figure 4 As shown, the inner circle of the waterproof cover 10 is provided with two 4mm w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com